Plastic Injection Molding Contract Manufacturing - contract injection molding

Author:gly Date: 2024-10-15

Procure materials faster, build products more cost-effectively, and ship directly to customers with the breadth and scale of our global supply chain network.

Short-run production services also enable requirements for automation, assembly, and preliminary production needs including clinical trial volumes.

Plastic overmolding services are widely used for combining materials with disparate properties – such as hard and soft plastics, or metal and plastic combinations. The primary advantage with overmolding is the ability to create products with improved ergonomic features, enhanced aesthetics, and optimized strength for the given application.From consumer electronics and mobile devices to automotive interiors and hand tools, overmolding is an extremely popular method for enhancing molded products for comfort, usability, and longevity. Plastic overmolding is essentially the two-shot molding operation, but completed in two separate molding runs: the first for the substrate material, the second for the secondary material. While this method still requires two tools, they are typically of a reduced cost & complexity when compared to two-shot molding.

Our experience producing plastics for the healthcare market includes medical device components, laboratory consumables, medical disposables, pharmaceutical packaging, and delivery devices. Our expertise means you can produce and deliver the highest level of quality and compliance to your customers, every time.

As the leading medical device manufacturer for volume production, we produce highly specialized plastic components and medical devices with the quality and regulatory readiness you need. We have facilities dedicated to the production of medical devices that are ISO 13485:2016 certified, FDA 21 CFR Part 820 compliant, and equipped with ISO Class 7 and 8 clean rooms.

Our single-source, standardized quality management system has subsystems for medical device production. Facilities that make medical devices are FDA registered and ISO 13485 certified with ISO Class 7 and 8 clean rooms.

Measure and correct dimensional issues during manufacturing of electrode making, grinding, and milling with our Self-Correcting Manufacturing (SCM) technology.

We recognize that advanced plastics play a key role in the future of product development. From consumer products to critical healthcare devices, plastics can set your product apart. Flex supports our customers through product design, tooling, assembly, packaging, and logistics, delivering reliable production outcomes through consistent quality control processes at every production stage.

Developmental tooling is critical to ensuring your components and products are highly manufacturable. Our dedicated engineering team partners with you every step of the way, starting with a working template for high-cavitation production molds.

Topics: Plastic Injection Molding Defects, Plastic Types, Quality, Texture, Choosing the right plastic injection molder

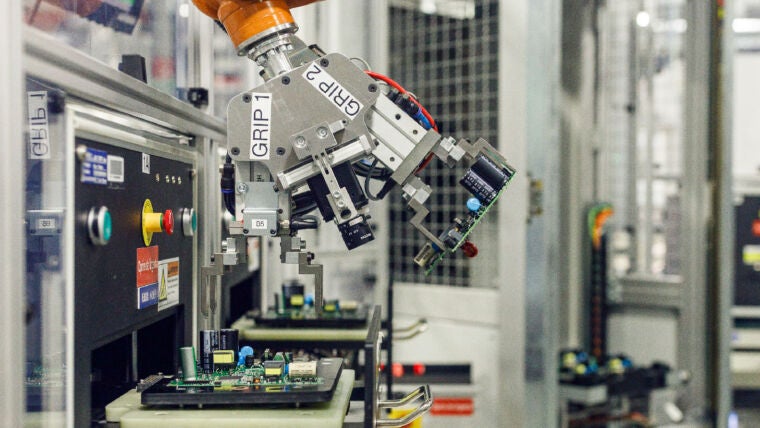

Set a new pace for operations with less effort. High-speed clean room assembly and packaging, in-house automation design and engineering, vertically integrated manufacturing of the molding process, and high-speed tool room automation all create efficiencies not possible with manual assembly.

Flex specializes in expert plastic injection molding, allowing us to provide complex plastic components in high volume at a low cost. Whether you require intricate multi-material parts or streamlined consumer packaging solutions, our advanced capabilities and expertise are ready to support your project needs.

Our expertise in complex injection molding and mold fabrication for consumer goods and plastic packaging solutions enables us to deliver myriad capabilities: developmental tooling for high-tolerance and rapid pre-production tooling, ultra-high-precision, high-cavitation tooling, high-volume plastic injection molding, automation, assembly, and more.

You can lower your Total Cost of Ownership (TCO) while improving customer satisfaction through faster, more reliable product delivery.

Our expertise in plastics custom mold manufacturing speeds production, cuts downtime, and streamlines the production of complex plastic components through our interchangeable core and cavity components.

AIM Processing is an experienced American manufacturer specializing in custom injection molding services and multi-material molding solutions. An ISO 9001:2015 registered domestic manufacturer based in the Denver, Colorado region, our company is committed to uncompromising quality, consistency, and responsive customer service.

Make our ultra-high-precision injection molding expertise yours. You can depend on our experience manufacturing plastics in healthcare devices, such as drug delivery devices, patches, inhalers, auto-injectors, syringe barrels and plunger rods, plastic implantable devices, and laboratory consumables.

Our Advanced Process Validation allows you to establish optimum processing parameters and validation criteria for FDA and other regulated specifications.

We deliver innovative, reliable, and scalable plastic molding solutions that enhance your products and brand, starting with materials selection and processing to help you select the right materials to meet application requirements, manufacturability, and environmental factors.

Multi-material injection molding has become increasingly popular across many different product applications, allowing us to create complex plastic products which take advantage of more than one material. For example, on handheld products, handles, and grips, we can use a much sturdier base material overmolded with a soft, ergonomic plastic to drastically improve comfort and the overall end user experience.

We use cookies on this site to enhance your user experience. You can learn more about our use of cookies and your choices here. By interacting with this page, you are giving your consent for us to set cookies. Dismiss

Through a combination of evaluating your products prior to investing in production molds and taking advantage of short-run production opportunities, you can get to market faster with a proven design.

We leverage our extensive experience and cutting-edge technology to deliver customized tooling design and fabrication solutions that meet the highest standards of quality, efficiency, and cost-effectiveness. Whether you require complex multi-material molds or high-volume production capabilities, we’ll make sure your components and products are highly manufacturable so you go to market with only proven designs.

We uphold rigorous quality control and testing procedures to guarantee that every mold meets the highest standards and use simulation software for the part and old design to optimize and prevent problems before the mold is build. We also use Finite Element Analysis (FEA) for products and assemblies to assess structural, acoustic, electromagnetic, and thermal performance.

Essentially, multi-material molding services let us combine multiple optimized plastics in a single molding product. There are three primary methods for multi-material injection molding, which we discuss below along with some of the advantages of each.Of course, choosing the most suitable method depends on the specific application requirements, material compatibility, and production considerations. Get in touch with the experts at AIM Processing and we’ll help you choose the most efficient, cost-effective method for your unique products.

As the leading medical device manufacturer for volume production, we have helped top multinational medical and pharmaceutical companies go to market.

We can help you with sterile assembly automation sized for multi-year demand, as well as a modular approach to final assembly. So you can scale your output as demand changes.

Your end result? Cost-effective, high-volume production of finished goods. And more importantly, you can minimize — or even eliminate — the potential for introducing human contaminants into your medical-grade products.

And along the way, your efforts support a sustainable future thanks to our partnerships with top certified suppliers using environmentally friendly practices.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly