Plastic Injection Molding Company - plastic molding company

Author:gly Date: 2024-10-15

Our specialized press-to-press transfer technique allows us to mold 360-degrees. It’s ideal when your application requires molding over metal inserts such as fasteners and magnets or other substrates such as structural reinforcements.

We design and manufacture most trim and fabrication tooling, as well as assembly fixtures, in-house. We’ll occasionally build prototype and production molds in-house, but we’ve found it’s usually more cost-effective to design in-house and partner with a dedicated, US-based moldmaker for the manufacturing.

Our two-shot injection molding company is located in Bad Axe, Michigan. You can drop us a note online, give us a call at 989-269-9791 or email us at plasticsales@geminigroup.net.

In the final stage of the project trial samples have been approved, and your product is ready for large scale production.

They purchased their own factory in 1996. The company has continued to expand with the major part of the business flowing from commercial and industrial clients. The directors are involved in all levels of the business – taking concepts from the design stage to development, tooling and finally manufacture. IMP has a long history of taking an idea from concept through development, to manufacture.

With decades of experience in two-shot injection molding, we’ve optimized our processes to drive cost out and maximize value for our customers. Our rapid prototyping, advanced molding techniques, and material expertise streamlines the production process from conception to production.

Our prototyping systems are fast and affordable, allowing you to critique the design and begin market testing within ten days of completion of your design.

Make informed decisions before full-scale production with our rapid prototyping capabilities. We evaluate the design and identify potential issues quickly and cost-effectively to speed up the product development process.

The initial briefing will focus on the products intended application whilst considering both it’s mechanical and financial viability.

From concept to production, our tailored design and engineering capabilities deliver cost-effective solutions for two-shot injection molded parts. We have the experience and confidence to take full design responsibility or serve as a design partner.

The two-shot injection molding process combines two different plastic resins in one machining cycle. To realize the full benefits of this process, you should choose two compatible materials that can form a molecular bond while simultaneously meeting the functional requirements of your part. Learn about the most common two-shot injection molding materials in our Two-Shot Design Guide, or contact us if you need help choosing compatible materials.

Two-shot injection molding eliminates the need for secondary processes such as welding and assembly. As such, piece prices tend to be lower for two-shot molded parts compared to multi-component single-shot assemblies. The tooling for two-shot, on the other hand, tends to be more complex and costly than single-shot. Therefore, two-shot injection molding is most cost-efficient for high-volume productions. Request a quote today to see if two-shot molding is the right solution for you.

Our two-shot injection molded parts contribute to the success of major industrial sectors, including automotive, lawn & garden, heavy equipment, and consumer products. Explore the wide range of uses for our two-shot injection molding solutions.

All tooling made by International Moulded Plastics is guaranteed and maintained free of charge while you continue to use us as your moulder.

Our two-shot injection molding company is ISO 14001:2004, ISO/TS 16949:2009, and WBENC certified. View our Certifications page.

International Moulded Plastics have long been regarded as a plastic custom moulding company that gets the difficult things done. As a leading plastic injection moulding with extensive experience, you can be confident that your new project design will be handled with all your specific requirements in mind from tool design, selecting the appropriate plastic material to the final manufacture of your part.

There are hundreds of materials suitable for two-shot injection molding and thousands of ways to adjust, blend, and fine-tune them. Our material experts can help you choose compatible materials that will form a molecular bond while simultaneously meeting the requirements of your part.

Two-shot injection molding is the ideal process for complex parts. As such, part design often requires a high level of refinement and sophistication. That’s why we’ve developed a Two Shot Design Guide. It provides the foundation you’ll need to start designing for the two-shot molding process.

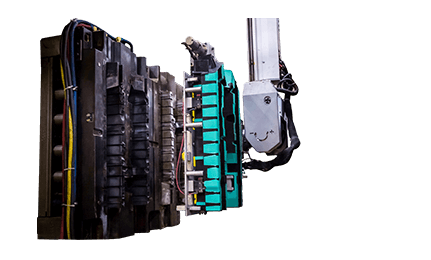

Our expertise lies in two-shot overmolding and insert molding. In addition, we utilize in-house secondary processes and high levels of automation to lower labor costs and improve accuracy and lead times. Our team can determine the optimal processes for your part.

Two-shot design can deliver a competitive advantage far above other molding processes, especially for complex parts. Learn the benefits of the process and explore the special design requirements needed to make it work in this free guide created by engineers, for engineers.

We’ve worked with hundreds of materials and additives, so we can accurately predict how processing will affect appearance. This expertise allows for precise color-matching and replication of design intent, enhancing visual appeal and brand identity.

We typically work with large customers such as automotive OEMs, Tier 1s, and Tier 2s. The majority of our accounts have volumes of at least 10,000 parts annually and have an annual buy over $100,000. If this sounds like you, we should connect.

This breadth of experience enables us to evaluate multiple processes and materials and recommend the optimal combination for your unique application.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly