PlasTech Molding Solutions overview - Explorium.ai - plastech molding solutions

Author:gly Date: 2024-10-15

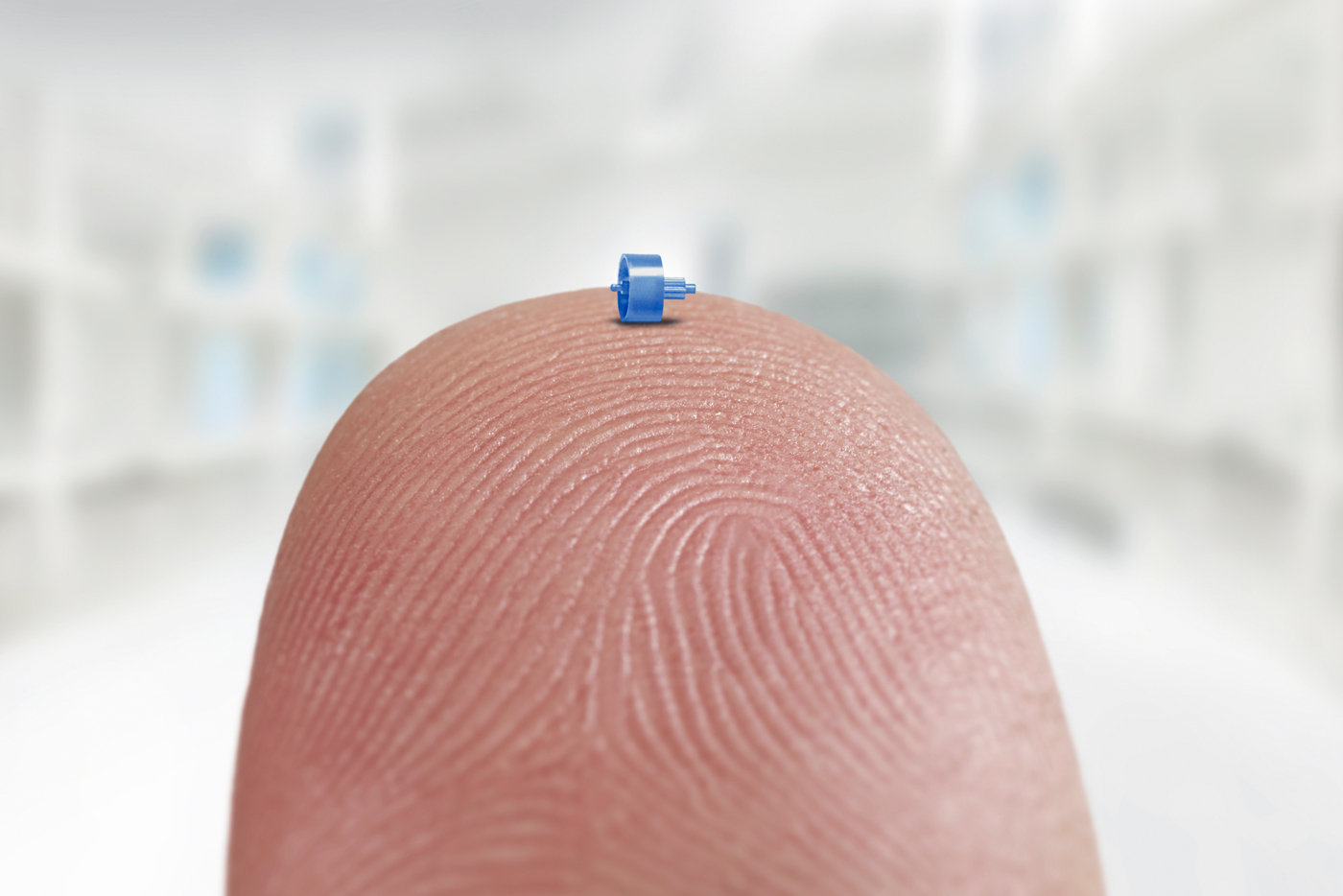

An electronics client approached LOR-TECH Plastics, LLC for the molding of an actuator that would be used within an electrical connector application. For this actuator, the client specified using Delrin® acetal resin because it bridges the gap between metals and ordinary plastics with its dimensional stability and fatigue resistance. We used an existing mold to create the .400" long actuator that had an outer diameter of .100". We have also produced actuators in six other sizes for this client.

SMC's micro molding capabilities yield 10,000 parts per pound of resin. Micro parts are considered less than 0.003 cubic inches and fall between 0.140 x 0.140 x 0.155 inches.

LOR-TECH Plastics, LLC has the expertise to produce injection molded components in a variety of plastic materials across a broad range of industries in. Please contact us to learn more about our services and offerings.

Copyright ©2023 SMC Ltd. All rights reserved. SMC and the SMC logo are registered trademarks of SMC Ltd. Privacy and Cookie Policy UnitedHealthcare’s Transparency in Coverage

At SMC we understand that precision matters when it comes to micro molded medical parts. We manufacture even the smallest parts while still holding precise tolerances.

True micro-molded parts can be smaller than the pellet of resin used, allowing multiple parts to be made from one resin pellet. Our efficient material and tooling techniques deliver exceptional yields of 10,000 parts per pound, including the runner. While miniature parts are the next step larger in physical size, they often have micro features. Knowing how to inspect and package micro and miniature components, assures parts to specification from the molding operation to the end device.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly