Pengetahuan Dasar Cetakan Injeksi - apa itu injection molding

Author:gly Date: 2024-10-15

To craft the mold, it needs to undergo accurate study, design, and testing. Many elements need to be taken into account for the mold. Here are some of the elements that need attention:

It differs from convection modeling in many ways, from the materials used to the mold created to the machine used in creating the product. This article tackles all you need to know about this technical process. By the end, you can assess if this is the molding process that you need for your next project.

Now that you’ve answered what precision injection molding is, you can check if you can apply it to some of your products. As stated above, it can also develop a wide variety of complex products.

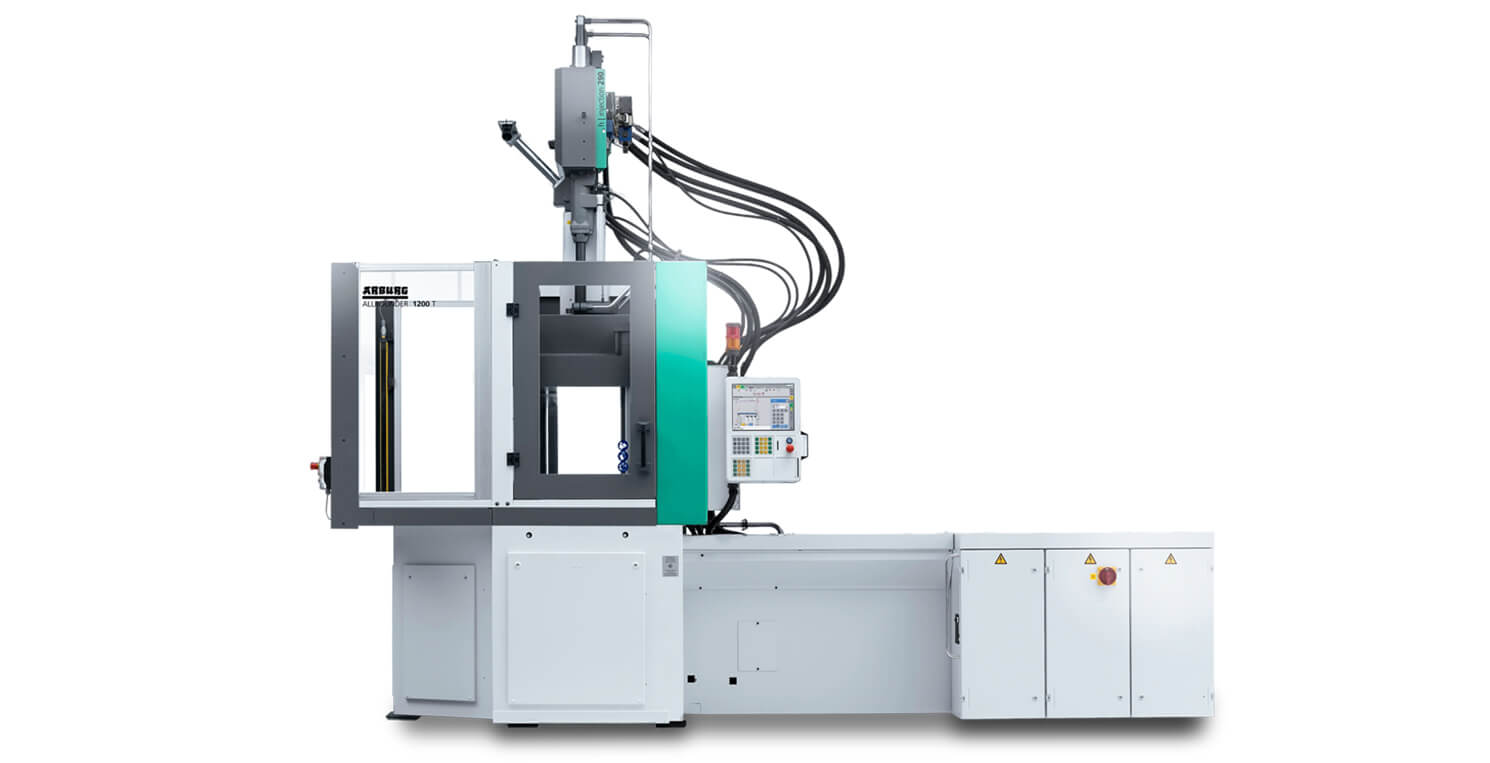

The entire process is automated and conducted through computers through an automatic handling system. It allows the producer to customize the process for the product needed to be molded.

A high-precision model is required when creating plastic parts that have tight tolerances. Each part made in a precise injection model needs to be identical. This process can only be applied to plastic parts that are placed and connected with other parts in a fixed form.

The precision made during this molding process is achieved through its mold. It needs to suit the design engineering requirements.

Products that are produced in precise injection molding are also comprised of complex geometric parts. These items have specific shapes that are needed for certain items in automotive, pharmaceutical, information technology, and medical fields.

Thanks to our experience in the plastic moulding sector, our continuous investment in R&D, and our know-how, we are the benchmark in the field of design and production of overmoulded gears.

But, what is precision injection molding? It is a highly technical process that makes use of precise molds. It is not used to develop whole products, instead, it develops more complex plastic parts.

The plastic components produced in precision injection molding require a tight tolerance. That means that the requirements for the product have precise and accurate procedures. When not followed, it can break inside the mold.

Metal insert injection molding has gained popularity in recent years as a cost-effective and efficient manufacturing process. This technique uses plastic molds to create products incorporating metal components, offering various advantages such as costs reduction and faster production times. In this article, we will describe the fundamentals of metal insert injection molding and explore its potential benefits for your business.

Out-sert moulding is a similar method to the traditional injection moulding process. The main difference is that out-sert moulding takes place on the local surface of a sheet metal.

All these applications have been developed internally with different plastics material such as PA46, POM, DELRIN, and PPA.

Polymer optics are used in precise injection molding. This is when CNC machining is used to mold the plastics into precise and calculated shapes. The machines have high pressure that helps improve the quality and precision of the plastic parts. They also manage to repeatedly create an accurate product.

Precise injection molding can cause plastics to shrink during the manufacturing process. That’s why its materials are different from other injection molding materials.

Precision injection models are made with tolerances between +/-0.02” and +/-0.01” or less. All elements mentioned are considered when considering the dimensions tolerance.

When materials have a high shrinkage capacity, they melt as they undergo the precise injection molding process. It ruins the product in the end.

An example of this would be ABS, a thermoplastic polymer. This kind of plastic can retain its elasticity while going through high temperatures. However, its shrinkage of +/-0.06 is still not appropriate for precision molding. Glass and other resin can be added to reach the desired shrinkage. These help the material absorb the excess heat while keeping the plastic stable.

Compared to plastic injection molding, this method produces precise plastic parts. It does not mass produce whole parts. These products that are made in the process replace high-precision metal parts from different industrial appliances.

Metal insert co-molding involves fixing a metal insert in the mold before injecting plastic. Despite its simplicity, there are important considerations for successful implementation:

Because of the precise products, the manufacturer should not rely on rapid tools for this method. Precise injection modeling is a slow and steady process that makes a high-precision tool.

If you’re interested in this process or other molding processes, message Richfields today. We offer various tooling solutions including precision injection molding. Don’t hesitate to reach out to learn more about how our services can help your next project.

The materials used for this molding process need to have a low shrinkage capacity. The shrinkage required is around +/-0.01” or +/-0.02”. However, many materials can’t reach this range.

Many molding processes are known to mass produce products that are used in daily life. However, various industries have parts and pieces that are too complex to be made with ordinary plastic injection moldings. A process called precision injection molding is used for such processes.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly