Overmolding material compatibility: a quick guide - plastic overmolding

Author:gly Date: 2024-10-15

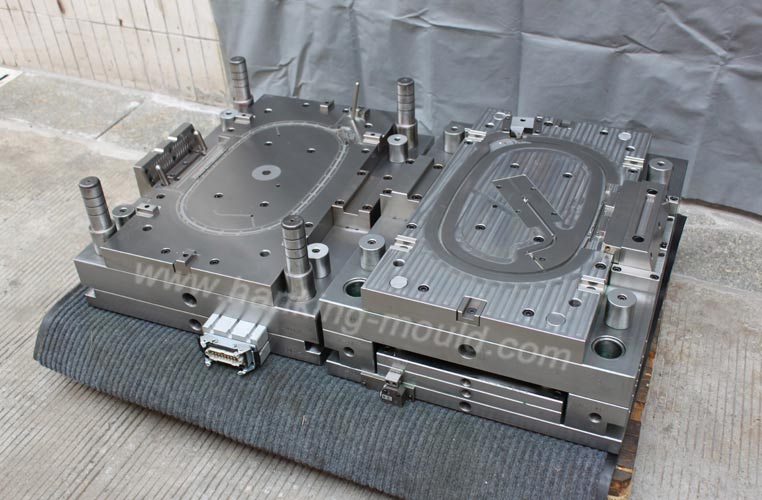

The plastic injection mold industry is an important part of the national high-tech industry and a valuable technical resource. We optimize the structural design of the mold system and make it more intelligent, improve the forming process and mold standardization of the part, improve the precision and quality of the mold manufacturing, and reduce the amount of grinding and polishing of the surface of the part. Our plastic injection mold can be the development trend of mold production technology in the next decades.

The industrial mold is an unbeatable benefit amplifier. Machining products with molds greatly improve production efficiency, and also saves raw materials, reduces energy consumption and costs, and maintains high product consistency. It includes side plate mould, pinpoint plate mould, three plate mould, reverse gating mould and stack mould.

Hanking Plastic Injection Moulds includes automotive mold, electronic mould, home appliance mould, medical mould, insert molding, industrial mould, prototype mold, 2K mould, multi-cavity mould and precision mould, and they can be applied in various lines such as industry, automotive, environment, electronic, and consumers.

An individual or company needs to work with the right team in this process, including an expert in engineering, to ensure they have the right kind of functionality they need with the type of design they want.

The process may require the designer to build more than one physical prototype to verify that there are no errors or flaws and ensure that the physical plastic prototype replicates the final product sold to customers.

A person or company can work with plastic experts at this stage to help make a 3D prototype to ensure that the plastic product design can be engineered for production.

After creating a virtual prototype, the person or company should build the physical one. The skills of a professional designer will be required in this stage.

Prototype mould is made for pre-testing of large production, such as product structure, part function analysis and produces small lot parts for other process verification. It can reduce errors in design and risks in the development, and reduce the time for training users, which improves the system's practicality, correctness and user satisfaction.

As the population is increasing, the medical segment is one of the fastest-growing markets, including disposable medical products as well as medical equipment internal parts.

Household appliances plastic parts basically include interior plastic parts mold and the exterior plastic housing and case, which we use on a daily basis.

The first step in creating a plastic prototype is to create a product concept or design. The concept can be written down or sketched on paper if one has many ideas running through their mind to help visualize the prototype in greater detail.

For those brainstorming a new part, prototyping is an essential process to achieving success. Developing a functional plastic prototype will help you find and test different types of plastic, so you can choose one with the strength, durability, color and cost that will suit your product.

Plastic electronic enclosures are used throughout our daily lives, such as remote control housing, plug plastic housing, electrical machine plastic cover, router housing, office appliances case, adapter charger housing mould, terminal block, mobile phone housing, terminal devices, computers products.

The demand for plastic parts in the automotive industry is increasing day by day. No matter how extreme the operating temperatures are and how harsh the chemicals, Hanking can provide a variety of engineering-grade thermoplastics.

Mold creation is the most critical stage in plastic prototyping. After the concept and design have been engineered, the actual molds can be made. Prototype injection molding is used in the process and involves the production of actual injection molded parts for functional testing.

There are three key steps in developing a plastic prototype, and each step requires a team of creative engineering minds.

There are two types of plastic prototypes, namely visual and functional. A visual prototype is made to give a company an idea of what the final product will look like. It does not have to function as the final product, and 3D printing is the quickest and cheapest way to develop it. A functional prototype is developed to function like the desired finished product, including the material used and the mechanics of how it works.

The concept creation stage involves brainstorming and sketching the design on paper. With advances in technology, engineers and artists can utilize CAD design software to create a digital rendering of the product.

One should ensure the important parts of the sketch are detailed, including the parts that are vital to the functionality of the product. Those who are not artistic can hire an artist to draw the sketch for them, as the clearer the drawing, the better the final product will be.

Engineering Resource Center says after creating a CAD model, “a digital mock-up of the product showing what the product is meant to look like, how the parts fit together, and how the product as a whole will function,” the CAD model can then be taken to a prototype injection molder to be made.

A computer aid design (CAD) software specialist can help put together a 3D prototype after being briefed on the concept or design as the work is done using various CAD software.

Once created, the design can be brought to a specialized plastic injection molder to determine the next steps. Some manufacturers, like K&B Molded Products, can perform the entire process in-house from design to prototype to tooling and beyond.

In HanKing Mould, we have a complete set of high-precision measurement equipment, they are all of the strict size requirements, product consistency, complex structure and durability. Our precision mould can offer full dimension FAI measurement reports. We have high-quality injection plastic molding molds for sale, contact us now.

K&B has a proven 6-stage process that provides full-service solutions. We help companies navigate plastic injection molding methods to streamline products and processes, save money and work smarter. We don’t just manufacturer the right parts, we evaluate the full process, helping companies deliver and outperform the competition.

At present, more than 90% of plastic products in our daily life are injection molded. The market prospect, capacity, and application are large and wide. The following are the basic review of plastic injection moulds' classifications.

The company may also work with a sales and marketing expert with knowledge of what appeals to a specific audience to start the marketing process and get a feel of how receptive the market is even at the idea-building stage. It allows the team to improve the product further depending on the feedback.

The second step in creating a plastic prototype is to develop a virtual prototype. The team should turn the design sketches from the first step into a three-dimensional (3D) model that will be used to make a real prototype. The company can use 3D to create the virtual prototype to help see how the final version of the design will look like. The company will need a skilled prototype designer to assist in this step.

A person or individual may also need a manufacturing specialist to help identify whether the parts needed can be created, and how complicated the process will be.

Insert molding refers to a molding process in which we prepare an empty cavity on two or more mold-specific metals, and metal material inserts into a mould and then injecting the plastic resin, and the molten material is bonded to the insert, cooled and solidified.

The multi-cavity mould can produce multiple workpieces in one injection cycle for increased efficiency. It comprises a multi-cavity of the same plastic part and a multi-cavity of different plastic parts.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly