Murray Plastics: Custom Plastic Injection Molding Company - plastic mold manufac

Author:gly Date: 2024-10-15

Plastic coating is the application of liquid polymers or plastic onto the surface of a workpiece through dipping/immersion. The result is a thick plastic finish for protective and decorative purposes. This gives the material additional...

Thermoforming is the process of heating thin plastic sheets to its forming temperature and stretching it over a mold which takes its shape. After cooling and setting of the molded plastic sheet, each part will be separated from its batch to form a single unit or product...

We can work with numerous materials and allow you to choose the best type for your application. Our production team is well-versed with many resins, such as Nylon, Ryton, PBT, LCP and many other formulations. With our custom plastic injection molding services, we can provide exactly what your industry requires

Our facility features cutting-edge machinery, including a six-axis robotic arm with laser displacement capabilities, ensuring maximum accuracy with a true position tolerance of ±0.002 inches. This advanced technology not only improves the quality of our products but also streamlines our manufacturing processes, allowing us to meet tight deadlines without compromising on quality.

High-Quality Injection Molding Tailored to Your Needs At New Concept Technology, we pride ourselves on being a leader in high-quality injection molding services. Our state-of-the-art facility is equipped with advanced robotic technology that enhances the precision and efficiency of our injection molding processes. This commitment to innovation allows us to deliver superior products that meet the diverse needs of our clients across various industries. Advanced Technology for Precision Our facility features cutting-edge machinery, including a six-axis robotic arm with laser displacement capabilities, ensuring maximum accuracy with a true position tolerance of ±0.002 inches. This advanced technology not only improves the quality of our products but also streamlines our manufacturing processes, allowing us to meet tight deadlines without compromising on quality. We can work with numerous materials and allow you to choose the best type for your application. Our production team is well-versed with many resins, such as Nylon, Ryton, PBT, LCP and many other formulations. With our custom plastic injection molding services, we can provide exactly what your industry requires Learn What Injection Molding Is

Closed cell foam is a type of foam where the “cells” are tightly pressed together and enclosed. It contrasts open cell foam, such as polyurethane, with interconnected open cells. With closed-cell foam, because none of the cells...

© Plastic Molding Manufacturers will keep your information private and secure. We will not share your email address with any third parties.

For over twenty years Custom Plastics & Innovations Inc. (CPI) has worked with many industries and sectoral groups including the automotive, electronics, medical, bio-tech, consumer products, business machines and industrial products. We are a single-source supplier of molds and plastic parts to the manufacturing sector.

Polyurethane molding is the process of fabricating or manufacturing plastic parts by introducing a urethane polymer system into a tool or mold and allowing it to cure. Like any other type of plastic, the excellent processability...

Fiberglass molding is a method for forming complex and intricate parts using fiberglass resin. Though there are several reasons for producing parts and components from fiberglass, the most pressing reasons are the...

Blow molding is a type of plastic forming process for creating hollow plastic products made from thermoplastic materials. The process involves heating and inflating a plastic tube known as a parison or preform. The parison is placed between two dies that contain the desired shape of the product...

Plastic injection molding, or commonly referred to as injection molding, is a manufacturing process used in the mass fabrication of plastic parts. It involves an injection of molten plastic material into the mold where it cools and...

New Concept Technology is your go-to company when you need high-quality injection molding. Our team will work with you to customize your order, ensuring you receive the perfect solution for your project. Reach out to us for a free quotation, and one of our team members will contact you.

When you partner with us, you receive more than just injection molding. Our customers experience many advantages, including:

At New Concept Technology, we pride ourselves on being a leader in high-quality injection molding services. Our state-of-the-art facility is equipped with advanced robotic technology that enhances the precision and efficiency of our injection molding processes. This commitment to innovation allows us to deliver superior products that meet the diverse needs of our clients across various industries.

There are various ways to mold plastic objects, but injection molding offers manufacturers several benefits, such as the following:

Rotational molding, commonly referred to as "rotomolding", is a plastic casting technique used to produce hollow, seamless, and double-walled parts. It uses a hollow mold tool wherein the thermoplastic powdered resin is heated while being rotated and cooled to solidify...

Our Benefits When you partner with us, you receive more than just injection molding. Our customers experience many advantages, including: Unmatched quality: We only use high-quality materials for our products so that our customers receive durable solutions. Remarkable customer service: We prioritize our customers, always going above and beyond to meet their needs and exceed their expectations. Competitive turnarounds: Our team has an efficient injection molding process, allowing them to deliver prompt results. Abundant services: We are a single-source supplier that provides an extensive array of services and handles every aspect of production. Precise products: Our robotic system ensures precision, accuracy and a tight tolerance. Why Use Injection Molding? There are various ways to mold plastic objects, but injection molding offers manufacturers several benefits, such as the following: Ideal process for mass manufacturing: We can streamline the injection molding process to mass-produce your items in a short period. Cost efficiency: Since we can mass-produce injection molding items, there is a lower production cost. Reduced waste: Injection molding produces less waste than other production processes, such as CNC machining, which reduces manufacturing costs. Consistent results: One major benefit of injection molding is that it provides consistency and reliability for high product volumes.

Custom Plastics & Innovations, Inc. | Plastic Molding Manufacturers | Home | Privacy Policy/Terms of use | List of Companies | Sitemap

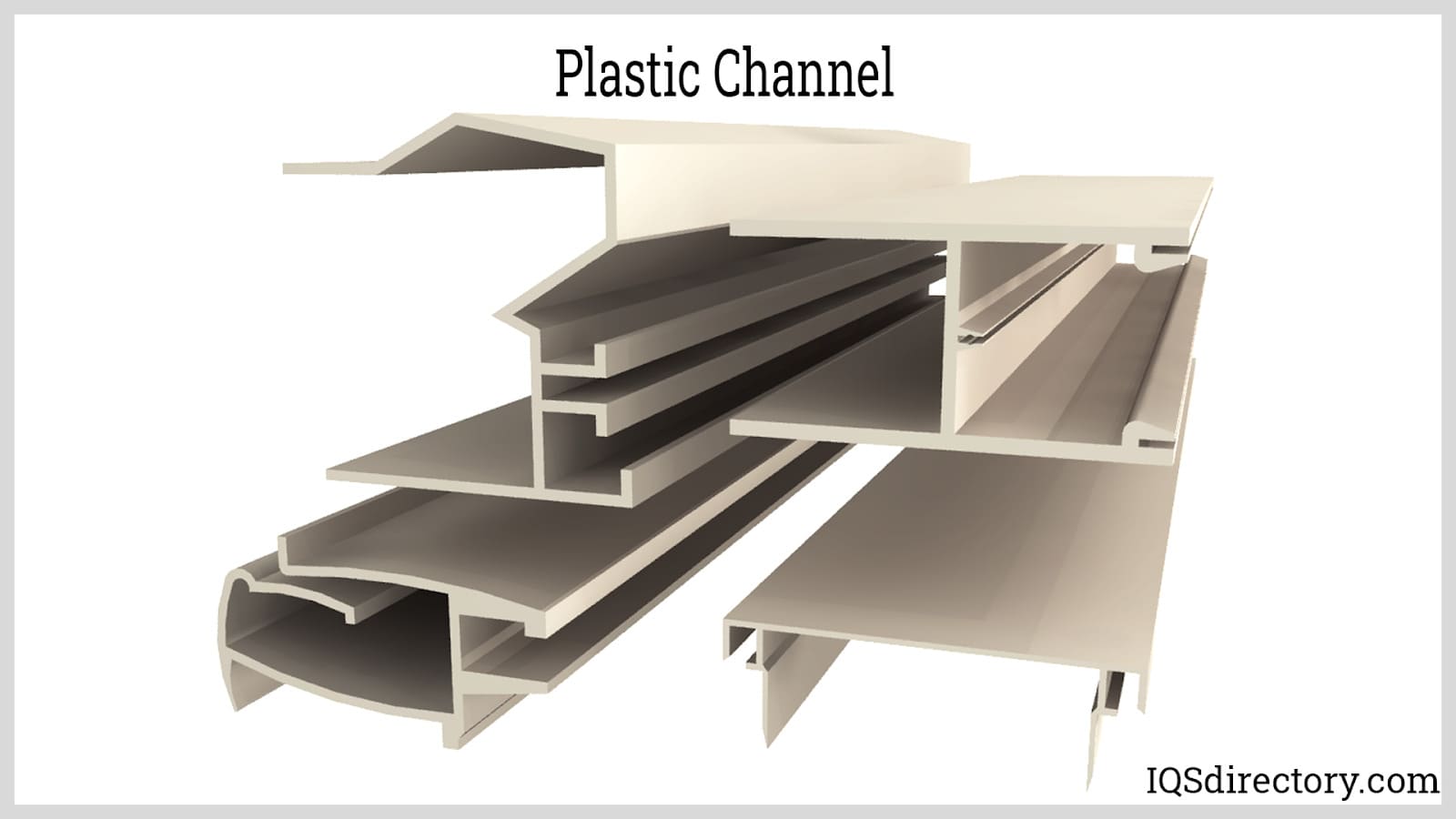

Plastic fabrication is the process of designing, manufacturing, and assembling a product made out of plastic material or composites that contain plastic. There are numerous plastic fabrication methods known today, considering the...

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly