Multi-Shot Or Double-Shot Injection Moulding - two shot plastic injection moldin

Author:gly Date: 2024-10-15

Rubber molding is a process of transforming uncured rubber or an elastomer into a usable product by transferring, compressing, or injecting raw rubber material into a metal mold cavity...

We offer quality new and used plastic molds, injection molding molds, blow moulding moulds and dies for plastic household products, kitchenware, and other plastic products. To contact Chinese mould makers, manufacturers and suppliers of plastic injection moulds, extrusion T Dies, extrusion profile dies, hot runner molds, air rings, PET moulds, compression moulds, molds for rotomoulding write to us at sales@plastemart.com

Password must be between 4 and 15 characters long, and may consist of hyphen (-), underscores (_), dot (.), and asterix (*).

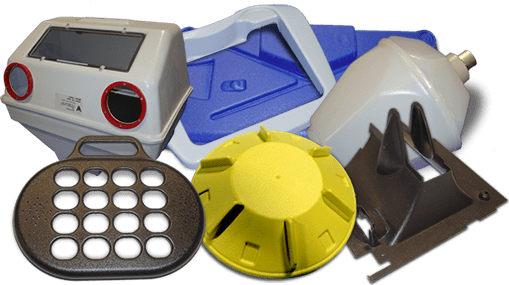

Plastic processes differ greatly in both the way they form plastic products and in the shape and structural integrity of the products they manufacture. Blow molding, for example, is nearly the sole method by which plastic bottles for beverages, household cleaners, and cosmetic products are made, as well as a range of low-cost toys and parts with low to medium performance. The extrusion process creates linear profiles, strips, and sheets with high structural integrity useful in many construction siding, trim, and furniture applications. Vacuum forming, or thermoforming, forms trays, linings, and thin plastic packaging from heated plastic sheets, while dip molding forms a variety of soft molds and plastic coatings. Other plastic molding processes use casts, or dies; injection molding squeezes melted (or plasticized) plastic resin into a closed mold, forming a solid plastic object, while rotational molding uses a type of gyroscope to evenly coat the inside of a mold, creating hollow parts with high impact resistance.

Contract manufacturing is a business model in which a company hires a contract manufacturer to produce its products or components of its products. It is a strategic action widely adopted by companies to save extensive resources and...

Metal stamping is a coldworking process that transforms sheets of metal into specific, preset shapes. It uses specialized tooling which involves the stroke of the punch that brings conformational change to the metal sheet...

Plastic Molding Manufacturing Companies | Contract Manufacturing Companies | Home | Request for Quote | Photo Gallery | Privacy Policy/Terms of use | List of Companies | Sitemap

Plastic injection molding, or commonly referred to as injection molding, is a manufacturing process used in the mass fabrication of plastic parts. It involves an injection of molten plastic material into the mold where it cools and...

Die casting is a high pressure metal casting process that forces molten metal into a mold. It produces dimensionally accurate precision metal parts that have a flawless smooth finish...

Password must be between 4 and 15 characters long, and may consist of hyphen (-), underscores (_), dot (.), and asterix (*).

The manufactured demand definition, often known as on-demand manufacturing or manufacturing on demand (MOD), is a relatively new idea in the manufacturing industry. In an on-demand manufacturing system, goods are only...

Metal fabrication is the process of turning sheet metal and other flat metals into predetermined forms. The process begins with sheet metal no thicker than a quarter inch. The metal is malleable enough to take on various shapes at...

Plastic molding processes vary greatly in cost. High-end plastic molding processes, such as rotational molding and injection molding, provide precision three-dimensional plastic parts with structural integrity and impact resistance a few other processes or materials can provide. On the other end of the spectrum, blow molding and dip molding processes offer very affordable options for long runs and mass production of containers and household commodity items. A wide range of plastic materials is molded through these processes, although some processes are more effective with certain polymers than others.

Forging is a metal working process that manipulates, shapes, deforms, and compresses metal to achieve a desired form, configuration, or appearance outlined by a metal processing design or diagram...

Screw machined parts are complex pieces that are typically cylindrical and threaded and a screw machined product is a family of automatic lathes for small to medium-sized components. Screws, bolts, pins, fittings...

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly