Mold Filling Simulation in SOLIDWORKS Plastics - injection molding solidworks

Author:gly Date: 2024-10-15

Click on the button below to be redirected to our contact us page and get in touch with an Injection Moulding specialist.

Injection molding is a widely used manufacturing process in the medical industry, offering numerous advantages for a variety of applications. Medical-grade plastics injection molding is used for medical devices, components, laboratory and facility equipment, and more. Among the key advantages of the injection molding process are its ability to meet the exacting specifications and regulatory needs of the medical industry, which we’ll discuss in further detail below.

Our experts can help facilitate your requirements anywhere along the product life cycle, from concept all the way through to manufacturing.

Medical suppliers have found that plastic injection molding medical parts, components and devices is one of the most effective ways to attain the quality and specifications they need in a cost-effective and efficient manner. Medical device plastic injection molding is used for applications such as:

With these tips in hand, you’ll be able to make an informed decision about the material and process that’s best for your medical device or component manufacturing.

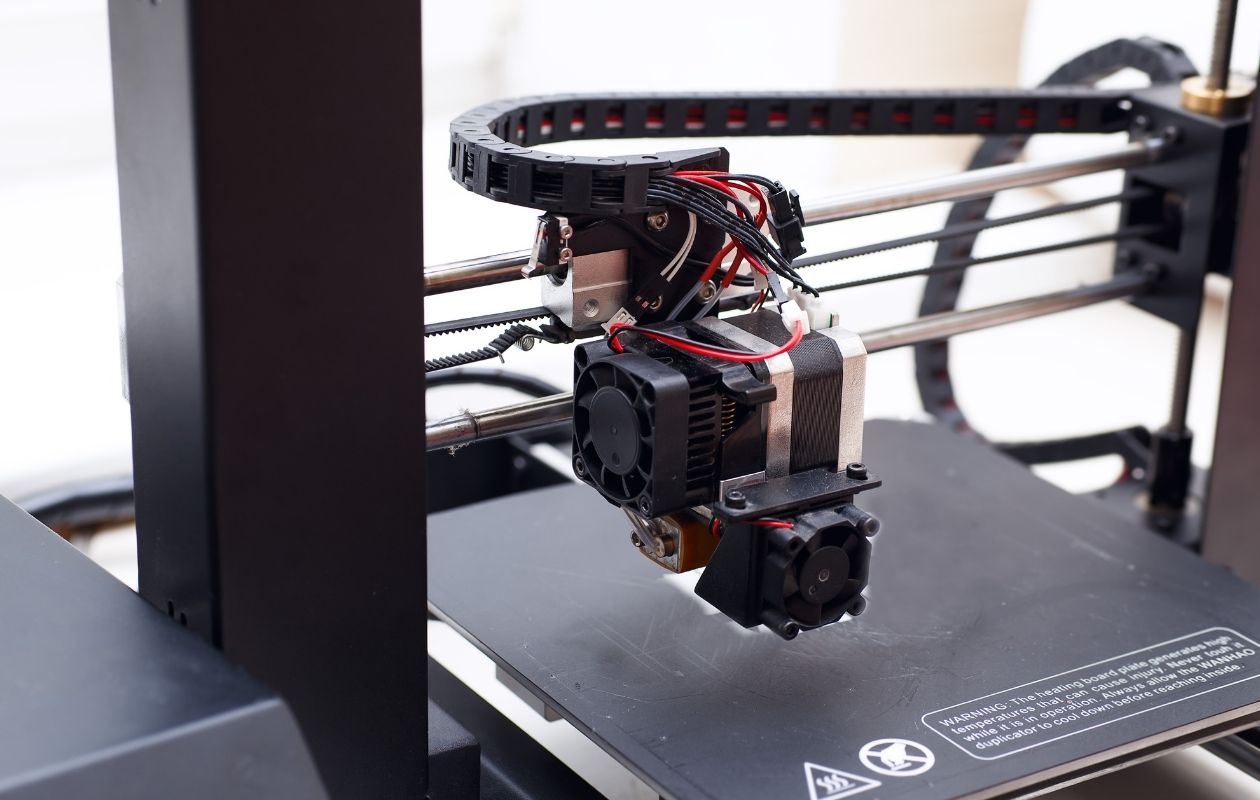

Injection Molding Australia have 3D printing machines which enable us to create a prototype of products from a completed 3D CAD design. Prototypes enable you to hold the product in your hand and give you an insight into how it will function prior to creating the tool for production.

Now that you understand the benefits of plastic injection molding for medical components and devices as well as the specific requirements these components must meet, we’ll take a look at some of the specific materials that fit the bill. In general, plastics offer benefits over other materials and processes in the areas of design flexibility, overall cost-effectiveness and speed of production. Consider the following materials for your project:

In drawing upon injection molding, medical industry suppliers and manufacturers gain access to several benefits inherent to the process and the materials available. These benefits include:

These are just a few of the ways medical device plastic injection molding is used. The process of plastic injection molding medical parts can be applied to nearly any area where durable, sterilization-friendly parts are required at high volume and with exceptional accuracy in production.

Based in Melbourne, our facilities use state of the art Injection Moulding machines to ensure the highest quality and consistency when it comes to your product.

Plastic injection molding for medical devices is a critical process where the stakes of failure are very high. As such, several considerations must be taken into account during the design, planning and manufacturing processes. These include:

Our state of the art service and support tools will guide you all the way from concept/design through to manufacturing, bringing your ideas to life!

Our experts will also work closely with you throughout the design and prototype phases to ensure that your product meets your precise specifications and operates at the highest standard.

With a combined 20 years experience in the industry, Injection Moulding Australia is the number one destination for all your injection molding needs.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly