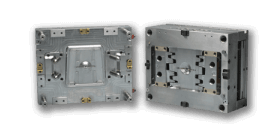

Medical Device Injection Molding - medical plastic injection molding

Author:gly Date: 2024-10-15

Nothing, the term "tool" is a broad term that could refer to many different types of tools or dies, but in our process it is interchangeable with the term "mold".

Yes, we have provided plastic product design services for over 30 years and have engineers on staff that are very knowledgeable about injection molded part design.

Yes, in 2023 we changed our branding to better reflect the full-service nature of our business, which is building rapid molds and providing rapid injection molding services.

![]()

Yes, we are a full-service, custom injection molder, as such we offer assembly services and a wide array of secondary services from printing to sonic welding.

Rapid Molding prides itself on swift turnarounds. Typically prototype injection molding lead-times are are 2-4 weeks. Whereas bridge tooling and production tooling lead-times can run 3 to 8 weeks depending on the size and complexity of the parts. In general, we typically deliver production molds 50% to 70% faster than industry standards, ensuring your projects hit the market without unnecessary delays.

Additionally, soft materials, like aluminum or mild tool steels, will not retain this "shiny" appearance after repetitive injection molding cycles. To truly provide an SPI A series finish, the mold requires special steel, like very specific grades of hardened 420SS with a very tight grain structure. Be sure to specify this finish requirement in your RFQ (Request For Quote) or discuss this with your CSE (Customer Service Engineer) before beginning your project.

With an array of material property benefits, molded thermoset parts are used in a variety of customer end-markets and applications that require a strong, durable material capable of withstanding aggressive elements. Thermosets will not degrade with exposure to certain chemicals, oils, and automotive fluids. In electrical applications and assemblies, thermoset parts protect internal components with superior dielectric strength and electrical insulation. In outdoor applications, thermoset components remain durable even in wide-ranging weather conditions including exposure to heavy sunlight and UV, rain, sleet or snow. Whether a product application functions in Alaska or Arizona, thermosets remain a preferred material choice of engineers and designers for challenging applications requiring heat-stable components. Cost-wise, thermosets are advantageously priced per pound against similarly-performing engineered thermoplastics.

Additionally, steel molds are much more durable, can survive fully automatic molding and are much easier to modify. If cost is driving you to consider aluminum molds, submit an RFQ and see what we can do for you.

There are 100s of available thermoplastic materials. These are just a few of the resins we stock. Many are also available with additives, like glass or carbon fibers, and fillers like talc.

• High volume production • Parts in 4-8 weeks • Capable of millions of cycles • Unlimited part complexity • Optimized automatic production • Highly competitive pricing

• Moderate volume production • Parts in 3-6 weeks • Capable of 300k+ cycles • Family and multi-cavity molds • Automatic undercut details • Automatic unscrewing molds • Fully automatic production

Bridge molding utilizes a bridge tool to accomplish low to moderate volumes of molded parts quickly and cost efficiently. There are small sacrifices in tool longevity with a bridge mold versus a production mold, but often times a bridge tool has more life than many projects need (300k+ cycles). Whereas rapid production molding spares no expense when it comes to tooling and is therefore the king of low cost, high-volume production injection molding.

Thermosets are synthetic composites or plastics that strengthen when heated but cannot successfully be remolded or reheated after being molded. Parts and components molded from thermosets offer excellent dimensional stability in high temperature and electrical environments. Thermosets offer material properties that provide resistance to corrosion, UV exposure, and aggressive chemicals such as oils and automotive fluids, making thermosets an ideal material choice for part assemblies exposed to outdoor elements and automotive applications. In electrical applications, thermoset molded components exude exceptionally strong electrical properties, electrical insulation, dielectric strength, and resistance to electrical arc and track. Thermoset materials protect the integrity of a molded part and internal electrical components and wiring throughout a product life cycle as parts will not degrade or disfigure under electrical exposure that thermoplastic molded part may experience.

Yes, we have several good suppliers that we partner with for retail packaging. For more information, contact your CSE (Customer Service Engineer).

Prototype molds are constructed for use in our proprietary system and for that reason the customer does not own these mold inserts and only pays a "tooling setup fee".

Yes, even when the design change is not a "steel safe" change. We build all of our molds from steel, as a result we can easily cut away more steel or "add" steel back in using modern welding techniques. This is a much more difficult task with aluminum and one of the many reasons we do not typically use aluminum to manufacture our molds.

• Low volume production • Parts in 2-4 weeks • Capable of 10k+ cycles • Undercuts & unscrewing details • Square corners • 55 to 1200 tons

No, due to the limitations in accuracy associated with this file format it is not a viable option for building injection molds.

In our process, there is no tangible difference in the parts. Some prototype molders may take shortcuts, like rounding off corners or eliminating water lines in the mold in an effort to reduce costs. We do not make these compromises.

Yes, but selecting the plastic material for each application is the customer's choice and responsibility. We have engineers with decades of experience who can digest your requirements and make suggestions, as well as, provide technical data on various material, but in the end you will need to make this choice.

Molding materials that are thermoset include Bulk Molding Compound (BMC), Phenolic, Epoxy, and Diallyl Phthalate (DAP). Bulk Molding Compounds are unsaturated polyesters and vinyl esters. Thermosets can be injection, compression, injection-compression, or transfer molded. The main molding or processing difference between thermosets and thermoplastics is that thermosets are molded into a preheated or hot mold at around 350F. The thermoset resin meeting the hot mold causes a chemical reaction, and gives the molded part its strong end properties. A thermoplastic on the other hand is molded into a cooled mold to form the molded parts, and does not offer the same stability thermosets offer in its molded properties.

We take care to restrict access to your data/information to a need to know basis. Each customer that registers on our website is afforded these standard confidentiality terms. For more information, contact your CSE (Customer Service Engineer).

If you need assistance with 3D CAD creation or modifying your part design for better results with injection molding, inquire with your CSE (Customer Service Engineer).

Yes, 2D drawings in PDF format are acceptable for inspection and communication purposes, but cannot be used as a substitute for the 3D CAD formats listed above.

Yes, all production molds, and most prototype molds, are eligible for acid-etched textures using dozens of industry standard patterns.

Absolutely! We have decades of experience with complex molding projects. We are well equipped to handle even the most intricate molds. We've successfully tackled diverse projects, providing precision and efficiency for both simple and highly complex parts.

Yes, we warehouse and maintain all molds in our possession for the life of the project. If the project becomes dormant for more than 12 months we will contact you to understand your intentions and future needs. We may charge a storage fee for molds held beyond reasonable dormant periods.

If you need assistance making your payment ask your CSE (Customer Service Engineer) to connect you with our orders department.

In scientific terms, a thermoset monomer must have three or more reactive ends, with its molecular chains crosslinking in three dimensions. Post-molding, thermosets have virtually all molecules interconnected with strong, permanent, physical bonds which are not heat reversible. Thermoplastic monomers on the other hand, only have two reactive ends for linear chain growth.

Ph: 630.543.1144 | Fax: 630.543.1525 info@woodlandplastics.com

It is important to note that aluminum can become "shiny" and appear to have a mirror finish, but that does not qualify as an SPI A series finish. For this reason your average prototype mold may not actually meet your project requirements.

Get prototype injection molded parts fast! With Rapid Molding you won’t break the bank doing it. Components ranging from 0.5″ x 0.5″ up to 20″ x 20″ have never been less expensive. Get a prototype injection molding quote right now, simply upload your 3D CAD file and answer a few questions.

No. In the 1990s we experimented for several years with aluminum molds. We found that modern high-speed machining techniques can actually remove more steel per hour than aluminum! This is due to the amount of energy released in ultra-high-speed machining. When removing high volumes of aluminum the energy actually makes the aluminum soft, nearly melting it to a liquid form. As a result the aluminum reaches a point of diminishing returns and UHS cutting of steel surpasses the removal rate of aluminum.

Many prototype molders only apply sand or bead blast textures. While we do offer this services, acid etching is more accurate and will last for many, many more cycles.

We provide injection molding services up to 1,200 tons in the US and up to 2,800 tons in Asia. The maximum part size will depend on the material selected and the part geometry, but as a general rule, injection molded parts may require 2-5 tons per square inch of projected surface area. For example, a 10"x10" part might require 200 to 500 tons of clamp force, depending on part geometry, nominal thickness, material selection and other factors.

In layman terms, molding or curing a thermoset is like cooking an egg or baking a cake. Once an egg is dropped into boiling water and cooked, it cannot revert to its original physical state as a yoke. Similarly, after thermosets are molded, it cannot be ground up and reprocessed or remolded.

We manufacture molds with all levels of complexity, everyday. Features like undercuts and internal or external threads are no problem. We can even incorporate these features into prototype molds. Molds that require multi-stage ejection, floating cores and cavities, reverse injection and ejection are all available to build your molds.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly