Latest Issue - pt injection molding

Author:gly Date: 2024-10-15

When tolerances and on-time-delivery are important, OEMs choose us for two-shot injection molded parts. We’re more than a manufacturer. We’re problem-solvers, working both with customers and vendors to build functionality, safety, and efficiency into everything we produce.

Feature papers represent the most advanced research with significant potential for high impact in the field. A Feature Paper should be a substantial original Article that involves several techniques or approaches, provides an outlook for future research directions and describes possible research applications.

If you’re new to two-shot plastic injection molding, you might think it is more complex, more expensive, or more time consuming than other plastic molding processes. Taken alone, those may be true, but two-shot also creates considerable functionality and cost savings.

Feature papers are submitted upon individual invitation or recommendation by the scientific editors and must receive positive feedback from the reviewers.

Manuscript Submission Information Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the special issue website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website. Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Micromachines is an international peer-reviewed open access monthly journal published by MDPI. Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2600 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

It requires high levels of technical expertise and attention to detail, and even the smallest mistakes can cost big money, especially in high-volume production scenarios. That’s why it’s critical to find a highly capable supplier. Look for excellent supplier quality scorecards, defined processes to mitigate against flash, flow lines, and short-shots, and contingency plans to expand capacity as your business and your two-shot molding needs grow. Once you find a supplier, involve them early on in the design phase of your part. They can identify potential problem areas and engineer value into your product.

Two-shot injection molding is the ideal plastic molding process for complex, multi-color, and multi-material plastic products, especially in high-volume production scenarios.

When a major automotive OEM failed a side impact crash test, they relied on their Tier 1 supplier and us to develop a two-shot injection molding solution to reinforce the vehicle’s frame.

You can rest assured you’re getting the quality you need at a competitive market price when you choose us for your two-shot molding solutions.

Two-shot molding allows multiple components to be molded with a single tool, reducing the amount of labor needed to run your parts and eliminating the need to weld or join components after the molding process.

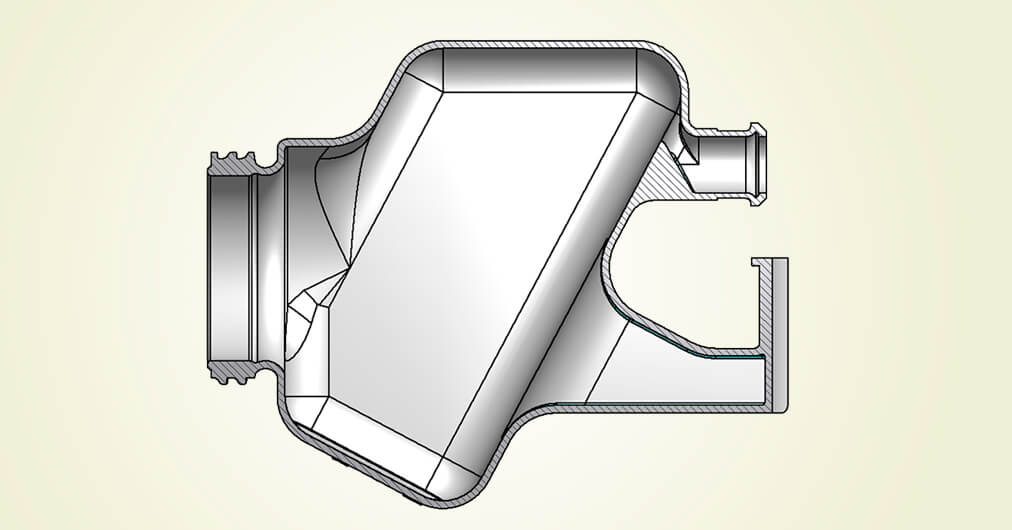

The first is similar to traditional injection molding: A shot of resin is injected into a mold and cooled to form a solid part. In the second phase, the just-molded part is transferred to a second mold via a rotating platen or a robotic arm, and receives the second shot of resin – in, through or around certain parts of the first molded part, depending on the design. The two plastic resins then form a molecular bond and the multi-resin molded part is cooled and ejected.

Editor’s Choice articles are based on recommendations by the scientific editors of MDPI journals from around the world. Editors select a small number of articles recently published in the journal that they believe will be particularly interesting to readers, or important in the respective research area. The aim is to provide a snapshot of some of the most exciting work published in the various research areas of the journal.

From consumer goods to construction, two-shot molded components are used in nearly every industry, but are most commonly found in applications requiring high functionality.

Injection molding (IM) is the primary method for the manufacture of polymer parts in mass production. A soft tooling process-chain that incorporates polymer 3D printing for mold fabrication will allow for an ultra-flexible manufacturing of medium-scale production series (e.g., from 1000 to 10,000 cycles by injection molding or similar). This method has the potential to replace the tool steel mold with a set of soft tool inserts made from polymer. Thus, the machining time and cost can be reduced significantly compared to conventional tooling processes based on milling, drilling, CNC tooling, etc. Additionally, additive manufacturing and novel process chains make it possible to produce parts with complex 3D geometry.

A special issue of Micromachines (ISSN 2072-666X). This special issue belongs to the section "D3: 3D Printing and Additive Manufacturing".

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Micromachines is an international peer-reviewed open access monthly journal published by MDPI.

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the special issue website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website. Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Micromachines is an international peer-reviewed open access monthly journal published by MDPI. Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2600 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Manuscript Submission Information Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the special issue website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website. Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Micromachines is an international peer-reviewed open access monthly journal published by MDPI. Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2600 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Maybe you’ve been turned off by a manufacturer’s quality or delivery issues? We’re here to tell you that you deserve better!

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2600 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Two-shot is carried out within a single tool, allowing for lower tolerances than other molding processes, a high level of accuracy and repeat-ability, and reduced scrap rates.

Two-shot injection molding reduces the number of components in a finished assembly, eliminating an average of $40K in development, engineering, and validation costs associated with each additional part number.

All articles published by MDPI are made immediately available worldwide under an open access license. No special permission is required to reuse all or part of the article published by MDPI, including figures and tables. For articles published under an open access Creative Common CC BY license, any part of the article may be reused without permission provided that the original article is clearly cited. For more information, please refer to https://www.mdpi.com/openaccess.

This Special Issue seeks research papers, short communications, and review articles that focus on novel development of soft tooling process chains and their applications. The scope covers all the relevant topics, including (but not limited to): tool life; precision and accuracy; novel process chains and applications; powder injection molding; materials modification; failure of the mold; modeling of the soft tooling process; process monitoring, control, and automation; functional surfaces; and metrology.

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the special issue website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Compared to other methods of plastic molding, two-shot is ultimately a more cost-efficient way of producing an assembly with multiple components. Here’s why:

The customer is a Tier 1 international automotive supplier with an emphasis on innovation and technology. The company’s products include automotive exteriors, closures, roof systems, and seating – to name a few.

Two-shot injection molding allows for the creation of complex mold designs that incorporate multiple materials for functionality that cannot be achieved through other molding processes.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly