Large-part Injection Molding China - large scale injection moulding

Author:gly Date: 2024-10-15

Metal insert injection molding has gained popularity in recent years as a cost-effective and efficient manufacturing process. This technique uses plastic molds to create products incorporating metal components, offering various advantages such as costs reduction and faster production times. In this article, we will describe the fundamentals of metal insert injection molding and explore its potential benefits for your business.

Out-sert moulding is a similar method to the traditional injection moulding process. The main difference is that out-sert moulding takes place on the local surface of a sheet metal.

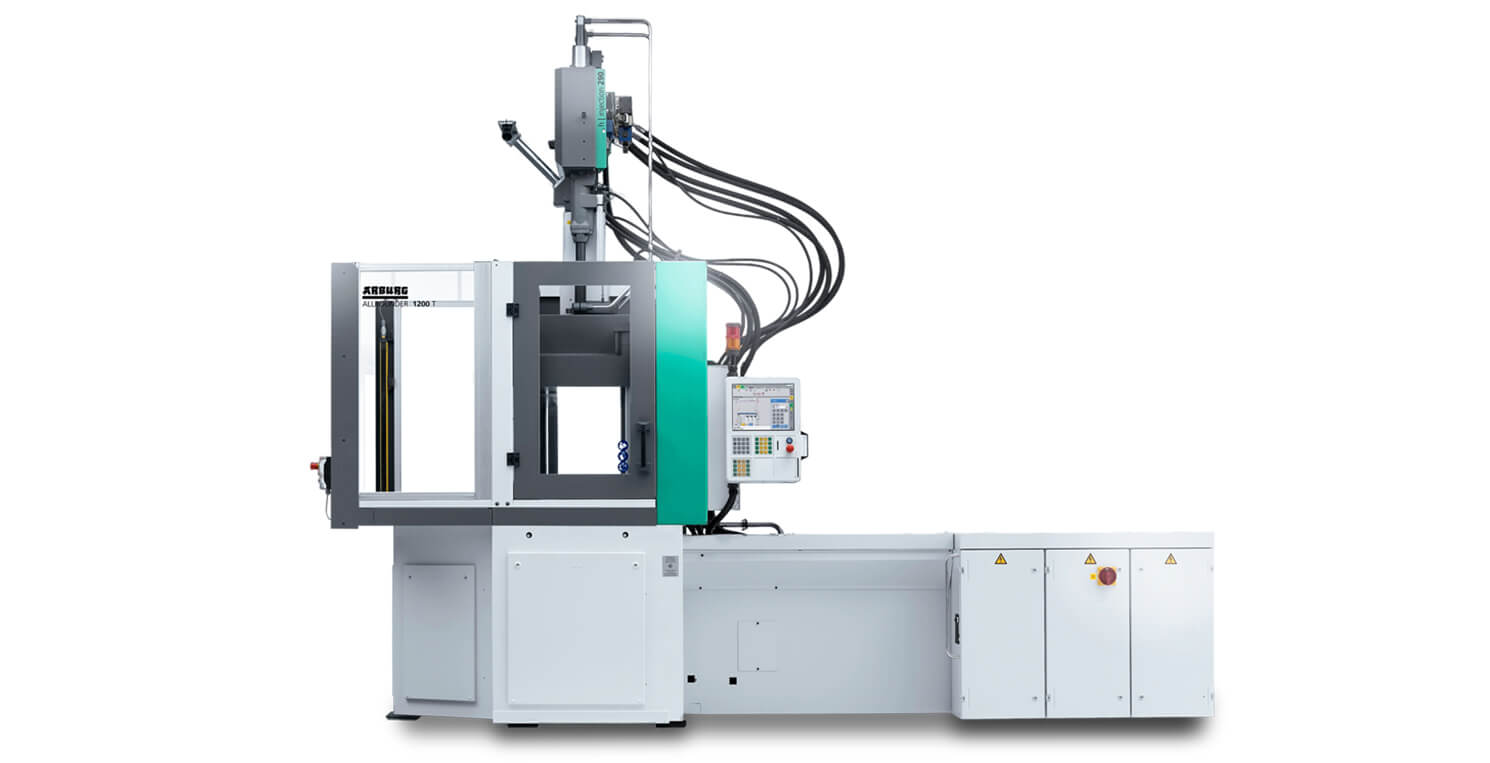

Moiron as an alternative to the expensive overpowered large injection molding machines that are typically over designed for R&D, Prototyping, Product Design, Education, Hobby and other Low-Volume production environments

Employ servo feedback mathematical precision torque control + high precision load sensors, to realize high precision measurement of plastics.

Metal insert co-molding involves fixing a metal insert in the mold before injecting plastic. Despite its simplicity, there are important considerations for successful implementation:

Our mini injection molding machine covers an area of about 1square meters,and can build mini injection workshop, saving investment of workshop and mold.

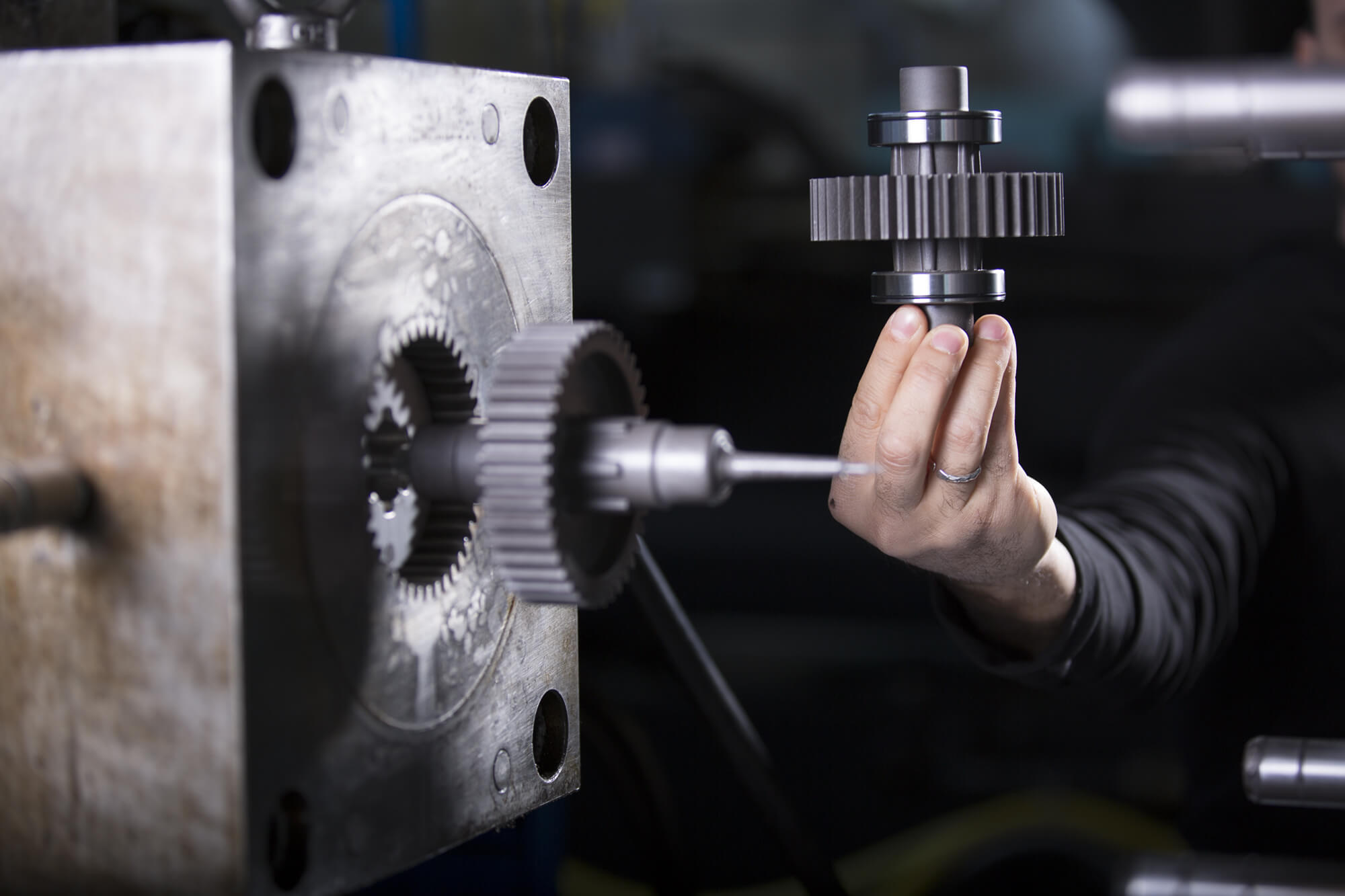

Thanks to our experience in the plastic moulding sector, our continuous investment in R&D, and our know-how, we are the benchmark in the field of design and production of overmoulded gears.

All these applications have been developed internally with different plastics material such as PA46, POM, DELRIN, and PPA.

The machine is especially designed for small parts; precise screw injection system make sure the high accuracy of minimum shot(even if shot weight<0.01g); adopt servo control system, 24 high accuracy absolute encoders with good stability and high accuracy Repeatability , improving the stability of product shaping

Servo energy saving injection press is equipped with high performance servo electric motor driving control system. Output power of servo motor varies as loading changes so more energy consuming is not existing. During keeping pressure state, motor rotating decrease with low energy consuming. During cooling state, motor is nearly not working. The shot accuracy is improved, at the same time electricity, water saved.

Servo control system uses MECHATROL+INK embedded CNC technology,Substantially increasing plasticized performance,switching speed of change.

Moiron is an automatic injection molding machine with a small 600mm*300mm*535mm. It is a good fit for low-volume (less than 100K/yr) production, prototyping activities, technical colleges, and hobbyists:

Servo motor is equipped with absolute encoder 24;if power failure or power outage to replace the mechanical parts,it also real-time memory location.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly