Kinsler Fuel Injection - Manufacturing, Sales and Service - injection manufactur

Author:gly Date: 2024-10-15

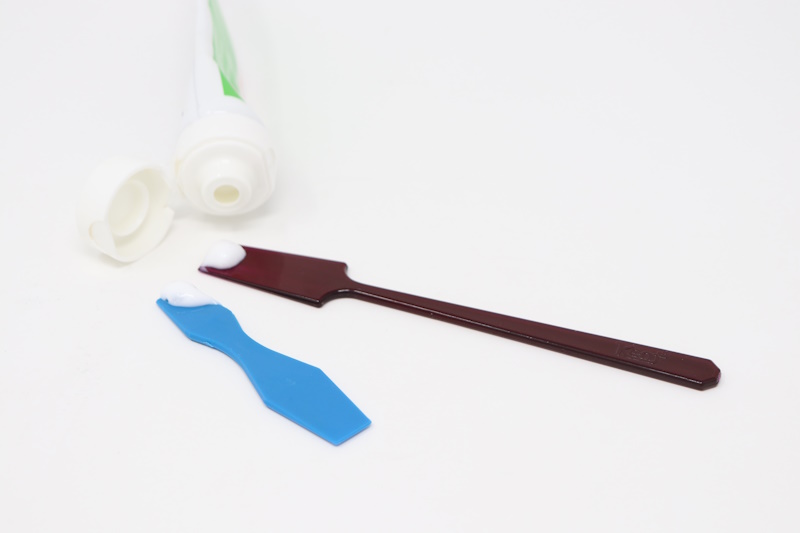

Our custom plastic injection molded industrial elements are made from start to finish, in-house in our Peterborough, Ontario facility. We create the artwork and design, implement the engineering and CAD programming, produce the dies and molds, and take care of all the details. You only have to deal with one company—no third parties required.

Custom plastic injection molding plays a critical role in the production of medical personal protective equipment (PPE). This manufacturing technique’s versatility, precision, and speed allows for the efficient production of high-quality, reliable PPE items that are essential in healthcare settings. The strict manufacturing process allows for the mass production of precise, reliable components that help to ensure the safety and health of medical professionals on the front lines.

One of the primary applications of custom plastic injection molding in medical PPE production is the fabrication of face shields. These clear, medical shields are a critical component of PPE, protecting healthcare professionals from splashes, sprays, and spatter of body fluids. Injection molding can rapidly produce durable, lightweight plastic frames and clear shields that are comfortable to wear for extended periods. Health Canada approved, our face shields are BPA-free, recyclable and FDA-approved, plus we have an MDEL medical-grade license.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly