Kickstarting A Business With Plastic Injection Molding - plastic molding busines

Author:gly Date: 2024-10-15

As the name suggests, the molten materials get compressed into the molds to form various shapes. Usually, this manufacturing process is popular in the mass production of plastic parts with similar shapes, sizes, and surfaces.

Rotational molding uses massive force and high temperature to let the plastic powder stick to the walls of the mold and form a hollow shape. This type of manufacturing is common in the mass production of plastic containers and bottles of various shapes and sizes. Rotational molding is most flexible for producing the smallest and the most intricate designs.

It is obvious that a trusted manufacturer with mass production will take the least time to deliver customized orders to the clients. The speed of production depicts the quality of the product and how much they are in demand.

Equated with rapid prototyping manufacturing, thermoforming involves melting thermoplastics into extruded plastic sheets by applying massive force and vacuuming the presence of air inside molders.

While looking for partners who will enhance your business with advanced prototyping methods and the latest industry trends, quality assurance matters the most.

Plastic prototyping methods are most common in the medical, packaging, automobile, and electronics industries. The global rapid prototyping market is increasing rapidly and is expected to reach USD 32.4 billion by 2031. This market is progressing with a growth rate of 14.9%, and thus, choosing plastic prototype marketing can be profitable for businesses.

From using the most advanced technology to providing quality assurance, Seaskymedical is one of those accredited and trustworthy medical device molding companies that any business can rely on. Seaskymedical is based in China and is also ISO-certified; therefore, you can be assured about the products you receive.

Similarly, a manufacturer who has expertise in plastic prototype manufacturing makes sure each product is passed through several quality inspections and each manufacturing process is carefully inspected to avoid faults. These quality inspection processes include strength tests, durability tests, temperature tests, etc. An expert manufacturer abides by the necessary regulations and offers products that are certified.

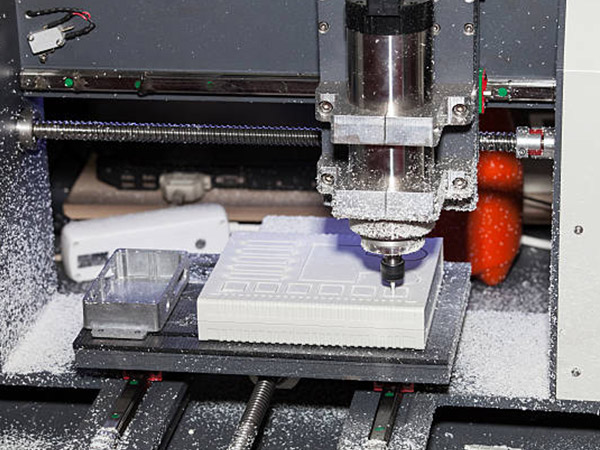

CNC machining technology is so advanced that it can create the fastest automotive prototypes for production. The CNC machining technology is so fast and efficient that they are often chosen over 3D printing prototypes. Not just plastics, CNC machining, is equally efficient in prototyping metals.

A manufacturer is very likely to offer its products at a rate that is comparatively low than that of the price of retailers. Most manufacturing companies sell their products at wholesale rates. Hence, the cost of production is also an important factor to consider. This doesn’t mean every manufacturer offering low-cost products is trustworthy, but the cheapest price can also degrade the overall quality.

Ever since the introduction of rapid prototyping, the production of plastic parts has become simpler with the help of high-speed casting, molding, and machining. If your business needs the most upgraded plastic prototype solutions, you must contact Seaskymedical and get your hands on high-quality product development, 3D printing, and injection molding solutions. In return, you get quality assurance and timely deliveries at affordable rates.

Prototyping helps assume accurate dimensions and reveal the flaws that the product possesses. Designing parts is undoubtedly an exceptional combination of innovation and creativity which gets converted to real-world efficient parts. Modern technologies like 3D printing models enable clients to imagine how the product will look and feel.

Prototyping is imagining a model before it is manufactured and produced physically. It is much like giving ideas the shape of a product design that will be converted into a physical form with the help of advanced engineering technologies. Prototyping is no less than art; it drives innovation and creativity and turns it into reality in the form of prototype plastic parts.

The experience of a manufacturer matters the most; the more years the company has served clients, the more experience it has in providing prototype solutions. Also, more experience means the manufacturer is aware of the industry standards.

The most common material used in plastic prototypes to create the best kinds of prototype plastic parts is thermoplastics. This variety of plastic is available in solid form, mostly in the form of colored pipes that can be melted and molded. Thermoplastics are mostly plastic polymers that can melt down in elevated temperatures and, at the same time, can be cooled easily to form a shape.

Prototyping before producing plastic parts is the best way of saving time and money. Simply put, prototypes are virtual models that give manufacturers a glimpse of how it will be in its physical form. This model is ready for mass production, but before testing and validating them is a waste of time and money in production. If any errors arise, it will be a total loss producing defective plastic parts.

The manufacturing process of thermoforming interestingly includes a female and a male mold. Both these molds are used for laying molten plastic and pressing them into sheets.

FDM or fused deposition modeling is often paired with 3D printing in plastic prototyping. This method is used for manufacturing products layer after layer; the layers are formed by molten materials, mostly plastic.

A seamless interior also eliminates cracks or crevices where bacteria or contaminants could accumulate, enabling rotationally molded containers and vessels to serve in high-purity manufacturing operations.

The mold is removed from the machine and the plastic part is carefully taken out of the mold. The resulting seamless thermoplastic piece can be machined to tight tolerances, painted, or otherwise finished and assembled with other parts.

CNC machining is suitable for various industries that need prototypes, such as the medical and automobile industries. CNC stands for Computer Numeric Control. Therefore, investing in tooling is unnecessary because everything is computerized.

Elastomers are perfect for molding; they are mostly available in the forms of silicone, isoprene rubber, synthetic rubber, natural rubber, EDPM, and so on. Elastomers are very common in the medical, consumer products, and aerospace industries. They are introduced to complex manufacturing methods like injection molding to make the most flexible plastic or rubber parts.

Even if technology is rapidly advancing, the traditional methods of prototyping plastic manufacturing are still prevalent. Many manufacturing companies worldwide, even to this date, stick to the traditional techniques that are equally efficient as upgraded ones.

As a cost-effective modern plastic rapid prototyping method, Vacuum Casting is fast, but it is only ideal for small-scale production, for instance, 20 units at a time. Several types of rubber and plastic components are used in this manufacturing process to fill them in casts and shape them. The vacuum feature removes the air bubbles inside the casts and molten materials.

Before beginning production on a full scale, prototyping helps manufacturers gain an idea about how the physical product is going to be. This helps avoid common and major mistakes in production and makes it easier to produce the most efficient plastic parts with perfect finishings.

Plastic extrusions are mostly common in manufacturing prototype plastic parts like tubes and wire insulation or pipes. This manufacturing process is also common in window and door frame-making, window blinds manufacturing, making windshield wipers, and so on.

Rotational molding is a manufacturing method that produces parts fabricated from polymer resins, which can offer excellent chemical and environmental resistance. The resistant properties of selected polymer resins are aided by the seamless interior that results from the rotational molding process.

From factories to day-to-day necessities, plastic is readily available and the cheapest resource for industries to make the best quality products. A common practice of plastic prototype manufacturing is much more evident in the medical industry. Using complex manufacturing processes like injection molding, a plastic injection molding company can apply high-quality plastic parts to various machines and purposes.

The properties of rotationally molded containers or vessels benefit numerous applications within multiple industries, including aerospace, agriculture, automotive, mining, metallurgy, pharmaceuticals, and semiconductor fabrication.

Precision injection moulding is a specialized process that offers unique benefits to various industries requiring high-precision …

In other words, you get access to world-class injection molding and plastic part prototyping solutions at Seaskymedical. From product development to the selection of materials, custom mold making, and exploring the best injection prototype plastic moulding, every process and service of the company meets industry standards. Each product is verified and tested before delivering it to the clients.

Seasky Medical serves you with medical injection molding solutions from design to tooling to material selection and manufacturing. Contact our specialized team and solve your problem now.

Mainly the quality of work of a manufacturing company depends majorly on the types of tests conducted, such as step-by-step product inspections, time-to-time machine maintenance, board certification, etc.

A highly economical manufacturing method commonly used in plastic prototype production, extrusion involves the melting and molding of materials by applying huge force. Extrusion is commonly used in high-volume production, and the process begins with melting plastic and ends with a well-shaped finished product.

Much similar to injection molding, compression molding is a time-tested process of manufacturing that is very versatile and is used in creating plastic parts of various shapes and sizes. Compression molding machines are used in mass production and often use materials like rubber, elastomeric plastics, silicone, EPDM, etc.

Thermoforming uses extremely high temperatures to melt the thermoplastic pipes and tubes and pour them to form durable plastic sheets that are pliable. These extruded plastic sheets can be cut and shaped in multiple ways to form different plastic parts.

Overall, rotomolded containers and vessels are valued for their ability to maintain their structural integrity and the durability and impact resistance they can offer, alongside their chemical and environmental resistance. Rotomolding also presents cost advantages compared to other manufacturing methods for an impressive return on investment.

This seamless interior minimizes weak points where chemicals could potentially penetrate or react with the material. The homogeneous nature of the plastic structure enhances its resistance to various chemicals and corrosive substances.

An integral part of rapid prototyping manufacturing, laser cutting and etching is used to cut, and engrave on plastic parts, often to shape them. The most common example of laser cutting and cutting is shaping the glasses of eyewear. Not just plastic, this method is applied to wood, glass, fabric, and so on. Laser cutting and etching methods are controlled by CNC machining.

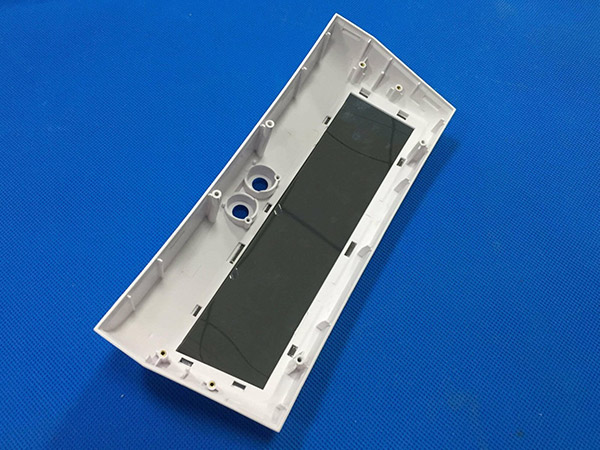

When using complex manufacturing methods like injection molding, special importance is paid to the mold design and the material. And even before that, the prototype design of the mold and the plastic part is passed through various tests to ensure there are no risks involved that can degrade the quality of production or the product.

Thin-walled, hollow parts that require tight tolerances can be manufactured using a rotational molding (rotomolding) process. Our consistent manufacturing process gives us the ability to create complex geometries in a single seamless part. We use proprietary resins and cost-effective, affordable tooling.

We use a variety of thermoplastic polymers in our rotational molding process, including polyethylene, polypropylene, and PVC. We also offer proprietary resins. Resin selection depends on the specific requirements of each individual project. Factors such as durability, chemical resistance, availability, and cost optimization play important roles to help determine the ideal material.

Since a force of air is blown inside the mold cavity to create a hollow component, the manufacturing method is known as blow molding. Not just bottles and containers, blow molding, is also used for manufacturing hollow plastic parts used for several industrial purposes. This process is used for mass production and is the best choice for manufacturing hollow products with the most complex geometries.

The cheapest and fastest way to produce plastic rapid prototyping is 3D printing. This additive manufacturing process creates three-dimensional prototypes and uses low-cost materials like thermoplastic and polylactic acid or PLA for production. Manufacturing companies seeking faster production often switch to 3D prototyping. Precisely, 3D printing allows you to explore plastic rapid prototype designs in the best possible way.

Plastic prototype manufacturing is a lucrative market, and the growing demand for plastic parts is evident. Even if the world is inclining more toward switching to eco-friendly materials, certain parts cannot be manufactured without the use of processed plastics. Therefore, plastic prototype manufacturing has a bright future ahead.

Whereas a company delaying the deliveries is likely less successful, having limited resources and backdated technologies. Therefore, the faster a company’s production, the more technologically advanced they are.

The mold is rotated inside of an oven. As the mold rotates, the polymer becomes molten and forms an even layer across all internal surfaces.

We use the rotational molding process to create aerospace parts and high-purity containers. We also have the capability to manufacture a wide range of molded pieces in our ISO Class 7 Clean Room for high-purity applications.

A mold is mounted to a multi-axis rotational molding machine. Thermoplastic resin is placed inside the mold, and in some circumstances, components such as mounting nuts or brackets are inserted at this time as well.

Also recognized as roto casting, roto molding, or rotational molding, this traditional manufacturing process occurs in low-pressure and high-temperature conditions. Rotational molding is applied in manufacturing hollow plastic parts containing a shell-like mold where the plastic powders are added.

All of these validation and testing processes have one purpose, testing the functionality of the prototype design before mass production is carried forward. Prototype testing and validation combine usability, functionality, and reliability to enhance the design process and production. Generally, these testing and validation processes are most applicable and useful for engineering designs.

Testing and validation are one of those initial steps before beginning mass production. The testing and validation process enables the elimination of existing errors in the prototype designs. Usually, validation and testing are carried out through three prototyping processes, including engineering validation testing (EVT), production validation testing (PVT), and design validation testing (DVT).

At Seaskymedical, you can expect top-notch services like custom plastic molding, medical plastic injection molding, mold making, 3D prototypes and printing, CNC plastic machining, silicon injection molding, and so much more.

Plastic prototype manufacturing is adapted mostly by any medical plastics manufacturer aiming to deliver top-notch plastic molding solutions to businesses and medical organizations. Mass production help cope with huge demands, and customizations improve the results.

Rotational molding offers manufacturers a cost-effective method to produce hollow, seamless parts using thermoplastic polymers. Polymer resin is placed in a mold, which is then heated and rotated on two axes to evenly distribute the melted plastic resin through the interior of the mold. As it cools, the plastic solidifies into the desired shape, vessel, or container. The rotational molding process yields components with a high strength-to-weight ratio, which also provides chemical resistance and corrosion protection.

Seasky Medical serves you with medical injection molding solutions from design to tooling to material selection and manufacturing. Contact our specialized team and solve your problem now.

Plastic rapid prototyping is one of the most common methods of manufacturing adapted by companies today for faster production and better quality maintenance. Rapid prototyping methods are the most modern techniques; they include:

Prototype designs are undoubtedly flexible and customizable. With prototyping plastic parts, manufacturers and their clients can introduce new changes in the models or molds. Almost every plastic prototype manufacturer allows flexible customizations. For instance, manufacturing companies help their clients design custom plastic injection moldproduced according to the requirements.

Choosing a trustworthy plastic prototype manufacturer amongst the crowd is challenging. However, the quality of the products, the production speed, and the company’s overall experience matter the most.

Thermoplastics are appreciated for their versatility and their ability to be recycled for reuse. Thermoplastics are very commonly used in plastic prototype manufacturing processes. They are melted and injected into pre-made molds to produce efficient and fully functional parts.

Often, a company’s work quality can be assumed from the various procedures for testing manufactured products, the types of raw materials chosen, and the time taken for production and delivery. In some cases, client reviews also help portray the overall quality of the manufacturer’s product and services.

Plastic prototype manufacturing includes flexible processes that involve 3D printing, vacuum casting, injection molding, and CNC machining. Prototyping helps factories design and visualize the parts before beginning the manufacturing process. A virtual model is created before the plastic prototype manufacturing process begins, and an appropriate method is chosen for production. These advanced manufacturing features enable rapid production and produce highly efficient plastic parts.

The tests are performed virtually with the help of CAD or 3D visualization and PDM tools. These help in creating physical mockups of products and finding out errors. Therefore, while prototyping plastic parts, testing and validation processes are significant.

Finding an ideal plastic prototype manufacturing company that promises quality products and services is incredibly challenging among thousands of choices. Seaskymedical is leading in plastic prototype manufacturing, and its primary focus is to serve clients with high-quality plastic molded products at affordable rates.

Extracted from nature, resins comprise synthetic compounds and can be used in several manufacturing processes. Resins are flexible synthetic materials that can be converted to solid or liquid form and mixed with chemicals to harden or soften them. Mostly, resins are used with molds for creating home decor items, jewelry pieces, coasters, furniture tops, and various plastic parts.

Plastic prototype manufacturing involves several combinations of complex technologies that enable the rapid production of plastic parts required by various industries. Prototype plastic molding or manufacturing is mostly in demand in the medical industries, where advanced technologies and manufacturing processes are used for manufacturing plastic parts such as syringes through specific methods like injection molding.

Extrusion is a lengthy production process, and the production results are shaped in the form of a continuous profile. This most widely used manufacturing method uses common plastic materials like polyethylene, nylon, PVC, polystyrene, and polypropylene. In some cases, the material used in extrusion manufacturing can also be thermoplastic or elastomer. All these materials are filled in the hopper and melted at temperatures between 350 to 520°C.

Known for their viscosity and elasticity, elastomers are polymers generally of a rubbery texture. Elastomers get their names from elasticity; they can be stretched and regained in shape. Synthetic elastomers, often made of petroleum, come into various industrial use, such as manufacturing over-molded parts. Apart from elasticity, elastomers are also known for their resistance.

The rapid growth in plastic prototype manufacturing benefits various industries, including the medical industry. There are usually two prototype techniques, traditional and rapid. Each of these manufacturing methods has variations and is applied to different types of production.

Plastics are one of the most flexible materials that can be molded in several ways to create the most useful equipment, parts, or devices. From the medical industry to the automobile, electronic, toy, or food packaging industries, numerous industries rely on plastics to manufacture their products today.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly