Introduction of multi-component injection molding process - multi component inje

Author:gly Date: 2024-10-15

If you're up for an even deeper dive in the world of plastic injection molding, check out this video from a previous blog post. In it, one of our capable engineers explains the ins and outs of injection molding. The video is about 12 minutes long, and packed with great information.

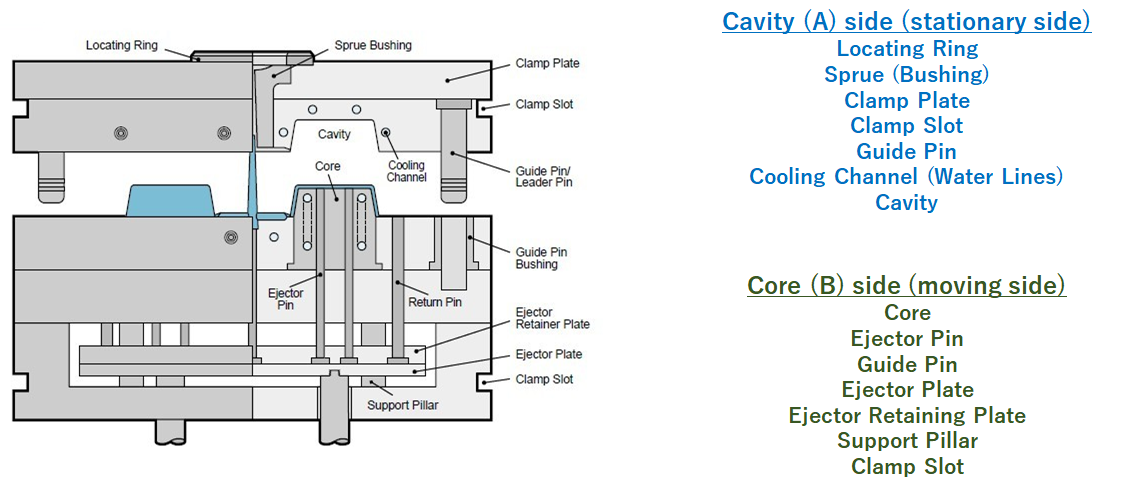

Cavity and core mold halves are insured to be in proper alignment during mold close by the use of guide pins (or pillars) and guide bushings (or sleeves).

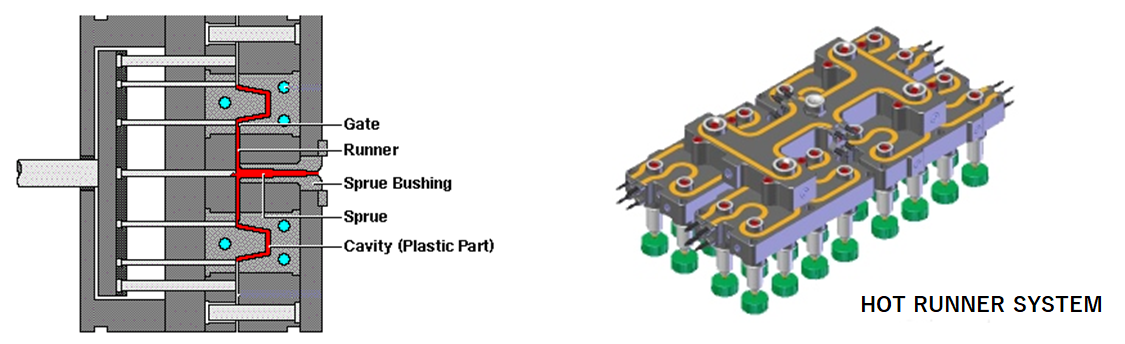

Plastic flows through the sprue bushing in a sprue, then to individual runners which take the material to the gates - the entry point of the material to the individual cavities.

So you've designed a product. You've gone through the RFQ process, sharing your CAD drawings with engineers who probably made even more tweaks. The part is going to be made of plastic using the injection molding process. But you've never made a plastic injected part before. There are a lot of new words and phrases being tossed around and you don't really know what they all mean.

Also if anyone here molds a lot of acrylic parts, has a good working knowledge of molding acrylic as far as processing and mold design I would appreciate it if you sent me a chat request. I would say comment below and I'll send you one, but I don't want randoms that visit here to send you a chat request in a few years asking if you wanna tell them how to mold acrylic.

The main problem we're having is when trimming the gate, it'll crack the part as well which is kind of expected when the gate is about 1/4th the thickness of the part and it's acrylic. If we go hotter the material gets brown/black specks, if we go colder the sprue freezes off. I thought about changing the material to PC or even another transparent material. I read somewhere that the mold material should be stainless or a high chrome tool steel, anyone know why that would be?

Cavities are areas of the mold where the part is formed into desired shape. Molds must be balanced, so there are typically only a certain number of cavitations allowed (1,2,4,8, etc...)

Mold halves are attached to the molding platens by the clamp plates. Mold clamps use large bolts to hold them in place; other machines hold the mold onto the platen with magnets.

An injection mold is a tool comprised of a series of parts that allows molten plastic to be formed and cooled in such a way as to create a discrete part shape.

The ejector pins are mounted in an ejector plate. The motion of the ejector plate forward allows the pins to move forward, pushing the part off the core. The ejector retaining plate holds the pins into the ejector plate.

We're attempting to mold a pretty small acrylic part, and it works, but I'm looking to make it work a bit better. We're using a 20:1 L/D screw with a 2.5:1 compression ratio, the part is a very small lens about the same diameter and length that is maybe 0.1" and the runner is much larger since we're using a 18mm dia screw. Barrel temps are an ascending profile from 340ºF at the feed throat to 375ºF at the nozzle. Mold temp is 160ºF and this is a cold runner mold. The gate is pretty narrow and kind of thin for the material, peak pressure is maxing out the limit of the press so we're planning on opening up the gate already.

Any tips/suggestions? I've molded a lot of ABS, nylons, polypropylene, polyethylene, polycarbonate, PC-ABS, etc. I just have never really molded acrylic.

East West is a global manufacturing services company focused on the realization of products, from design through distribution. As specialists in onshore, nearshore and offshore manufacturing, we offer a seamless path to scale and an exceptional speed-to-market strategy while driving down costs and adhering to the highest quality standards. We are one integrated family, working together to support our customers throughout the entire product lifecycle. Our vision is to make the world a better place – cleaner, safer, healthier and smarter.

Filed Under: Plastic Injection Molding, Injection Molding

No one would blame you for looking for a glossary of terms right about now. Fear not. Below, we break down the components of an injection mold in simple, easy-to-understand language. It even includes labeled cutaway drawings. I promise, if you didn't understand how an injection mold worked before, you will after reading this.

Plastic is injected hot and is cooled by cooling channels that allow conduction to cool the part. Working fluid is typically water, although oil can be used in high temp applications.

EDIT: Just wanted to say thank you all for the suggestions and tips, they're very much appreciated. I really do love how helpful this community has been and hopefully will continue to be and I'm thankful we have the active members able to contribute and discuss these kinds of things.

Liquified plastic is pushed through the nozzle of the barrel of the molding machine. The nozzle seats against a surface on the mold called the sprue bushing and locating ring, which help center the nozzle to the mold.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly