Injection Molding Part Design for Dummies (For Dummies) - injection moulding for

Author:gly Date: 2024-10-15

Low volume injection molding is a production method used to manufacture small quantities of plastic parts. This process is ideal for businesses with lower production requirements, as it allows for the creation of high-quality parts without the high cost of traditional injection molding methods. We know low volume injection molding also as rapid tooling .

Are you looking for a reliable and affordable low volume injection molding service for your small-scale production needs? Look no further than Injection Molds China ! We specialize in providing high-quality injection molding solutions for customers across a variety of industries.

Fitchmun, D.R. and Mencik, Z. (1973) Morphology of injection moulded polypropylene. J. Polymer Sci., Part B, Polymer Phys., 11, 951–971.

Kalay, G., Bevis, M.J. (1999). Injection molding of isotactic polypropylene. In: Karger-Kocsis, J. (eds) Polypropylene. Polymer Science and Technology Series, vol 2. Springer, Dordrecht. https://doi.org/10.1007/978-94-011-4421-6_47

Ready to take advantage of our low volume injection molding services? Contact us today to get a quote for your project. Our team of experts is here to answer any questions you may have and provide you with the high-quality parts you need to succeed. Thank you for choosing Injection Molds China!

At Triple-c Ltd ( an injection molding company in china), we understand that not all businesses require large-scale production runs. That’s why we offer low volume injection molding services to meet the needs of customers with smaller production needs. Here are some reasons why you should choose our services:

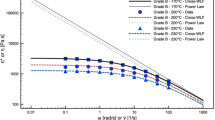

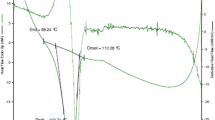

Kalay, G. and Bevis, M.J. (1997) Processing and physical property relationships in injection moulded isotactic polypropylene 1. Mechanical properties. J. Polymer Sci., Part B, Polymer Phys., 35, 241–263.

Injection molding is one of the widely used methods in the processing of isotactic polypropylene (iPP), where a screw in a heated barrel rotates to transport, melt and pressurize the polymer in the barrel, and then reciprocation of the screw injects the melt into the mold. Processing parameters have a very strong influence on the morphology and hence the physical properties of the molded product. This section discusses the effect of main processing parameters on the morphology and properties of conventionally injection-molded isotactic polypropylene. The application of shear controlled orientation in injection molding (SCORIM) for converting iPP into molded products is the subject of another chapter in this book, which presents the morphological changes induced in SCORIM with the objective of enhancing physical properties. These chapters together present the fundamental characteristics of injection-molded polypropylene which may serve as a guide to the more informed processing of iPP, and to the realisation of optimum physical properties.

Kalay, G. and Bevis, M.J. (1997) Processing and physical property relationships in injection moulded isotactic polypropylene 2. Morphology and crystallinity. J. Polymer Sci., Part B, Polymer Phys., 35, 265–291.

With low volume injection molding, we can produce as few as 100 parts, making it a cost-effective solution for businesses that require small quantities of parts for testing, prototypes, or limited production runs.

Trotignon, J.P., Lebrun, J.L. and Verdu, J. (1982) Crystalline polymorphism and orientation in injection moulded polypropylene. Plastics Rubber Processing Applic. 2, 247–251.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly