Injection Molding Machine - LS Mtron - plastic injection molding press

Author:gly Date: 2024-10-15

100 Innovative 3D Print Projects You’ll Love Introduction In the ever-evolving world of technology, 3D printing stands out as a revolutionary tool that empowers creators,

Injection molding is a widely used manufacturing process that allows for the production of complex and precise plastic parts. Two variations of injection molding, two-shot molding and overmolding, offer unique capabilities and advantages. In this blog post, we will explore the differences between two-shot molding and overmolding, helping you understand when and how each technique is used in the manufacturing industry.

Exploring Metal Filament 3D Printing: The Future of Additive Manufacturing Introduction In the ever-evolving landscape of 3D printing, metal filament 3D printing has emerged as

Two-shot molding, also known as two-component molding or 2K molding, is a process that involves injecting two different materials into a single mold to produce a finished part. The two materials are typically different types of plastics or a combination of plastic and a different material, such as rubber or metal. Key points about two-shot molding include:

Best Dual Extruder 3D Printers in 2024 3D printing technology continues to evolve rapidly, offering new capabilities and enhanced performance. One of the most significant

Usefulness in the military and aerospace industries: The military and the aerospace industries are very similar to the medical industries. Unlike many fast-moving consumer goods (FMCG) industries, these industries do not always require a large volume of parts and products. In this case, they rely on short run molding to produce a limited number of accessories and parts.

Does not need any minimum order requirements: High-grade steel molds are used for larger production runs. However, if you are looking to produce several hundreds of certain materials, you don’t have to pay for a minimum amount of products. Simply use the short run injection molding process to mold as many products as you want. In this production system, you are not restricted by any volume requirements.

The Future of Automotive Parts: How 3D Printing is Transforming the Industry In the fast-paced world of automotive manufacturing, innovation is key to staying ahead

In the medical industry: In a lot of cases, medical instruments are needed for specialized uses and will require a few hundred parts and accessories to be produced. It is perfect to use the short run molding for low production runs with high product quality.

We usually run into injection molded products in different stores at all times. Such products are often from big companies that make a high number of these products every year. Every year, they make use of injection mold technology to create a large volume of products. In some cases, they make millions of these products every year to be distributed across the world. This shows that this production model is suitable for large production runs. But what if you want to produce a new product in a few thousand or less? What if you want a low-volume on-demand production process that requires less time and costs? All of these objectives are possible when you use “short run plastic injection molding”. For many people, this is a relatively new process that comes with its advantages.

Produce goods of high quality: People often think that short run molding cuts corners and does not offer accurate dimensional tolerances as well as quality. However, the fact behind this production process is that it offers very high dimensional tolerances. It also provides excellent surface quality while also supporting high-volume injection molding processes. It offers exceptional quality when it comes to fitting different parts together.

CREO vs. SolidWorks®: A Comprehensive Software Comparison In the world of computer-aided design (CAD), two names frequently rise to the forefront: CREO and SolidWorks®. Both

Enhancing Electronic Products with Vacuum Casting Technology In the fast-paced world of electronics, precision and quality are paramount. The demand for innovative and reliable electronic

There are many short run injection molding companies around. However, you need to choose the best option. A reliable injection molding company will offer you all the benefits of this type of molding as we have highlighted above. Many such companies have a great deal of expertise in short-run projects. Additionally, these companies may offer similar production solutions with the use of 3D and CNC machines. This is because all these machines can be used for supporting or complementary services during an injection molding project. This is necessary because, in reality, many of these production systems are used to support each other. Then again, they are more suitable for specific projects that may not require the use of any other production technology. A reliable manufacturing company will provide the best short-run injection molding services. They will also help their customers solve the different problems as seen in short run injection molding systems. It is common to use a manufacturer that has completed thousands of injection molding projects for different customers.

Two-shot molding and overmolding are both valuable techniques in injection molding, offering opportunities to create complex, multi-material parts with enhanced functionality and aesthetics. Two-shot molding enables the bonding of two different materials during a sequential injection process, while overmolding involves adding a second material over a preformed substrate. Understanding the differences between these techniques will help manufacturers choose the most suitable approach for their specific applications, taking into account design requirements, material combinations, and process complexity. By leveraging the capabilities of two-shot molding and overmolding, manufacturers can achieve innovative solutions and differentiate their products in today’s competitive market.

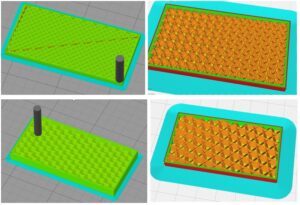

Exploring the Fascinating World of Infill Patterns in 3D Printing 3D printing has revolutionized the way we create objects, allowing us to transform digital designs into

Keep posted on the release of Coupon Code. The latest news of 3D Printing, CNC Machining, Injection Molding, and Silicone Molding…

Overmolding, also referred to as insert molding, is a process in which a second material is molded over a preformed substrate or insert. The substrate can be made of various materials, such as metal, plastic, or even another molded part. Key points about overmolding include:

It calls for low initial costs: Higher-grade aluminium or lower-grade steel costs less when compared to that of the high-grade steel needed for large production runs. Certainly, high-grade steel can be used to produce thousands/millions of parts, but short-run injection molding is more suitable for low-volume production.

Exploring the Best 3D Printing Settings for HIPS High Impact Polystyrene or HIPS is a standout choice in the world of 3D printing. Known for

Production of trial parts and prototypes: There are certain cases where you need more product samples and you can’t just fully rely on the 3D printing machine. When this is the case, you can rely on short run molding to produce more samples for you in less time. This is a lot better than using 3D machines for prototyping which can be greatly limited.

Exploring Shapeways Alternatives: Finding the Right 3D Printing Service for You In the rapidly evolving world of 3D printing, Shapeways has established itself as a prominent

The Best CAD Software for 3D Printing: A Comprehensive Guide In the dynamic world of 3D printing, choosing the right CAD (Computer-Aided Design) software is

Short run plastic injection molding is a production process that is also known as small batch or low-volume injection moulding. This production process requires reduced capital and a shorter time to develop. This molding system is used for the production of simple plastics through high-grade aluminium or low-grade steel injection molds. High-grade steel injection molds are used in large-volume plastic production runs. The short-run plastic injection molding is best suitable for injection molding production that needs less than 10,000 parts to be produced.

Exploring the Best Desktop CNC Milling Machines In recent years, desktop CNC milling machines have revolutionized the way hobbyists, makers, and professionals approach fabrication. These

Short-run injection molding is used commonly for the production of high-quality goods. A lot of niche industries rely on this production process to create a low amount of products and accessories each year. It can be used in various ways such as:

IN3DTEC rapidly delivers prototyping & scaled production on demand to help project designers and engineers accelerate new product introduction. We make excellent products from your ideas.

Huizhou Djmolding Co., Ltd, established in 2010, is a leading plastic injection moulding and mould manufacturer in China. Djmolding is a low volume manufacturing companies specializes in plastic mould and plastic parts production for household appliances, medical equipments, electronic equipments, safety equipments as well as monitoring system.

Used for producing limited edition cars and vehicles: Short-run injection molding is used extensively in the production of exotic cars. Many exotic cars are built in very few numbers. This is because it costs money and time to put them together. They are produced by using short run injection molding technology. This molding system can be used to ensure high quality as well as bespoke aesthetics.

FreeCAD vs. Autodesk Fusion®: Which CAD Software Reigns Supreme? When it comes to computer-aided design (CAD) software, two names often come up: FreeCAD and Autodesk

automotive injection molding companies Best Top 5 Low Volume Injection Molding Companies china low volume injection molding contract manufacturing low volume Custom Low Volume Plastic Parts Manufacturing custom plastic injection molding china injection moulding of liquid silicone rubber Low-volume injection molding cost low-volume manufacturing china Low Volume Injection Molding low volume injection molding canada low volume injection molding companies low volume injection molding company low volume injection molding europe low volume injection molding in usa low volume injection molding manufacturers low volume injection molding services low volume injection moulding uk low volume low cost plastic injection moulding low volume manufacturing low volume manufacturing companies low volume manufacturing processes low volume manufacturing service low volume manufacturing services low volume manufacturing strategies Low Volume Plastic Injection Molding low volume plastic manufacturing low volume plastic parts low volume plastic parts production low volume production plastic parts low volume production sheet metal low volume silicone molding metal pressing in low volume production plastic injection molding manufacturer plastic molding low volume production pvc low volume manufacturing mold custom factory online Short Run Injection Molding short run injection molding cost short run plastic injection molding small batch injection molding small batch plastic manufacturing small plastic parts manufacturer small quantity injection molding small volume manufacturing small volume silicone manufacturing

Djmolding is plastic injection mold maker in china,as a china plastic injection molding manufacturer supplier factory,we supplying high-precision plastic injection products,low volume injection molding for low volume manufacturing service,high volume injection molding,quick-turn injection molded parts and so on.

It can accommodate a wide range of material options: When it comes to resin options, there are no limits to using short-run molding. There are thousands of available resins that you can use for this production process. In addition, you can also apply the resins used for higher volume molding for this production process.

For more about what is short-run injection molding as an industrial process,you can pay a visit to Djmolding at https://www.djmolding.com/low-volume-manufacturing-service/ for more info.

It helps to reduce the overall production time: Short-run injection molding helps increase the turnaround time of parts production by a matter of weeks or days. This usually depends on how complex the mold designs are. This is highly beneficial in comparison to high-grade steel molds which usually take months for production to be completed.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly