Injection Molding for Custom Automotive Components - automotive plastic injectio

Author:gly Date: 2024-10-15

In industry, we often find injection molding systems. This technology is more complex and requires advanced technical knowledge. An injection molding machine allows a high production rate and a precise quality of the produced parts. However, we made the choice of a hydraulic press because it is a machine which is, throughout the world, much more widespread, less expensive; therefore easier to obtain and to use.

We are a leading blow moulder and are in search of a closed unit or a running business involved in manufacturing of blow moulded packaging items upto the size of 10 liters. We prefer bu......

Our company is into manufacturing of fillers and compounds since 2006 We have 3 running lines - 1 Single screw Kneader and 2 Twin screw extruders with Under water pelletizers Total In......

Complete Metallising facility for sale which includes the following equipment plus approximately 100 tons per month of existing business. - 1700 mm Galileo Metallizer - 1675 mm Polytype......

Cylinder Engraving Factory: We have the cylinder engraving factory as follows: A) Art working: 1. G5 Computer, 2008 2. PC Computer, 2008 3. Artpro Software, Upgrade 2008 4. Epson Pr......

A running factory manufacturing machinery is for sale at Gujarat. Unit established since 1987 manufacturing plastic processing machinery. The proprietor desires to retire and hence ......

The operators who interact with the hydraulic press must be aware of and respect the information relating to the use of the machine, the risks of using the machine, and the appropriate safety practices.

Before any use, visually check the mechanical condition. Periodically check the condition of the equipment (see maintenance sheet).

Running plant for Sheets WE HAVE SOPHISTICATED PLC CONTROLLED CO-EX SHEET PLANT. WE CAN PRODUCE SHEETS OF PP, HIPS, HDPE AND ABS UPTO 1450 MM WIDTH AND THICKNESS FROM 0.45 MM TO 6.5 MM......

Password must be between 4 and 15 characters long, and may consist of hyphen (-), underscores (_), dot (.), and asterix (*).

Preventive and corrective maintenance activities must only be carried out by a person trained for this purpose. Each intervention must be recorded in order to keep a history of the maintenance actions carried out.

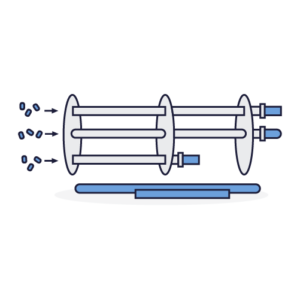

The hydraulic press is a machine for shaping the molten plastic coming out of the Extruder or the Sheet oven. The hot viscous plastic material is placed in a mold fixed to the hydraulic press The jacks that compress it are activated and cause the molds to close. The pressurized plastic spreads around the mold until it cools and the plastic sets.

![]()

A work zone around the machine is defined by a marking on the ground. Access near the machine, whilst it is in operation, is permitted only to trained and equipped operators.

The hydraulic press that we have on board is equipped with two large plates. These allow us to accommodate large molds, for example to make sheets.

The hydraulic press is equipped with two plates, one is fixed and the other is mobile. Actuated by jacks, the movable plate guided by four columns approaches the fixed plate. The cylinders apply even pressure to the element between the plates. The molds installed on the hydraulic press usually consist of two shells (fixed part and moving part) which are strongly pressed. The pressure exerted by the hydraulic press distributes the hot plastic over the entire footprint of the mold.

Why this choice? We have no choice but to add this machine into our production system due to its simplicity of design and use.

Kolsite PVC Pipes Type: 52/25 No.: 2 Production capacity: 150 mt/month (both) Type: 65/22 No.: 1 Production capacity: 150 mt/month Type: 90/22 No.: 1 Production capacity: 2......

The hydraulic press is equipped with a Jobsite Information Sheet which includes all the information necessary for the use of the machine in good safety conditions. It must be positioned in view of all operators using the hydraulic press.

Compounding Facility machines and Plant. 1) Two Extruders : I) 70 mm Screw Diameter with 90 Kw Motor twin screw extruder with a output ranging from 380 to 475 Kg/hr. Complete PLC......

Safety features guarantee the safety of operators on the hydraulic press. Make sure they are correctly installed before use:

Multilayer flexible packaging factory with running business on sale Product Milk Packaging Film LDPE / LLDP / MLLDPE Edible Oil Packing Film Material used:-LDPE/LLDPE/HDPE Industr......

Password must be between 4 and 15 characters long, and may consist of hyphen (-), underscores (_), dot (.), and asterix (*).

Before carrying out any maintenance, adjustment or repair intervention requiring partial or complete dismantling of parts of the shredder, it is necessary to follow these protocols.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly