How to Make A Hard Plastic Mold - HITOP Industrial - hard plastic molds

Author:gly Date: 2024-10-15

Plastic injection moulding can be used to manufacture items as small as a bottle cap or as large as a car body panel. The process uses both thermoplastic and thermosetting plastic materials. Depending on the product you’re manufacturing, each has clear benefits:

Click on the button below to be redirected to our contact us page and get in touch with an Injection Moulding specialist.

Thermoplastic – Is strong, has a high shrink resistance and is easy to bendThermoset – Has enhanced chemical resistance, heat resistance and good structural integrity.

During the process, plastic material is fed into a heated barrel, mixed, and forced into a mould cavity where it cools and hardens to the shape of the mould.

Our injection moulded products can: • Be manufactured in PP • Be colour matched to your company brand colour or any colour you choose including pearlescent and metallic • Be manufactured to order. We do ask for a minimum order quantity of 2500 units to avoid a set-up fee if the product is not a stock item. Explore our product range to see the standard packaging options and other custom engineered products that we can supply and manufacture • Be supplied to a range of industries such as mining & resources and packaging to name a few.

With a combined 20 years experience in the industry, Injection Moulding Australia is the number one destination for all your injection molding needs.

Get in TouchContact us today and see how we can supply you with the right rigid plastic packaging product or any plastic caps or closures.

Based in Melbourne, our facilities use state of the art Injection Moulding machines to ensure the highest quality and consistency when it comes to your product.

Our experts will also work closely with you throughout the design and prototype phases to ensure that your product meets your precise specifications and operates at the highest standard.

Our state of the art service and support tools will guide you all the way from concept/design through to manufacturing, bringing your ideas to life!

Our experts can help facilitate your requirements anywhere along the product life cycle, from concept all the way through to manufacturing.

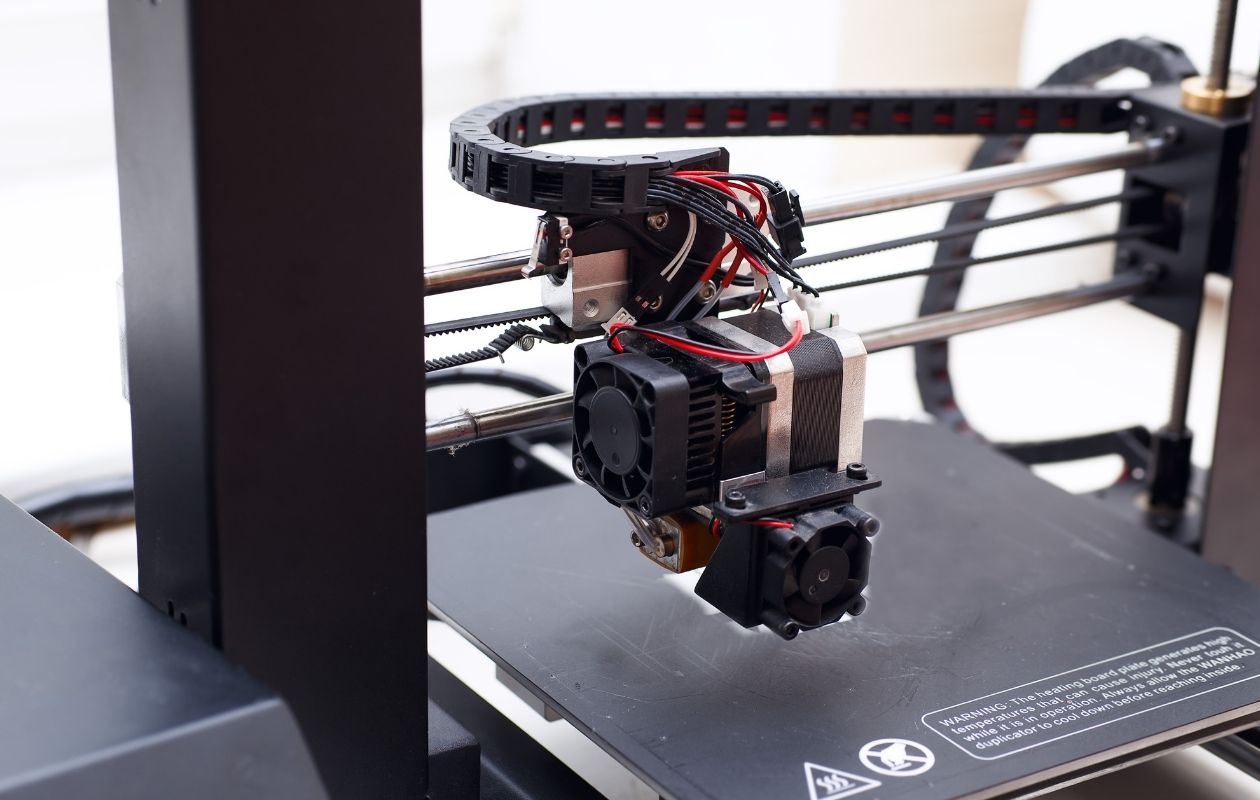

Injection Molding Australia have 3D printing machines which enable us to create a prototype of products from a completed 3D CAD design. Prototypes enable you to hold the product in your hand and give you an insight into how it will function prior to creating the tool for production.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly