How Much Does Injection Moulding Cost? - low volume injection molding cost

Author:gly Date: 2024-10-15

Using the latest technology’s including Stereolithography (SLA) and Fused Deposit Modelling (FDM), Supaflow Engineering will work with your ideas to develop 3D drawings and provide prototypes within days.

This ensures that your final products will fit the description and function you desire, and eradicates any possibility that your part is either too big or too small for its purpose by allowing us to alter your 3D designs before beginning any toolmaking process.

Our automotive customers have come to rely on our ability to deliver high-quality, low-cost plastic injection moulded parts, tools and components for vehicles across the UK and beyond. However, we don’t just work in this single sector. We are also a leading supplier to defence and security, agriculture, construction, retail, automotive, packaging and lighting.

These state of the art robots have (as the name suggests) six axis, which allow the robot to move and rotate in a large assortment of ways. Our team has been able to innovatively include these robots and program them to work alongside the machines as your parts are being made, making Supaflow Engineering a much more competitive company, as we are able to reduce labour costs and continue packing and assembling 24 hours a day after closing hours.

Our quality standards are exacting and everything that we produce is subjected to rigorous safety testing and quality control.

Our moulding department’s facilities are modern and innovative, with machines and robots utilised to maximise production efficiency.

Address: 64 - 66 Nestor Drive, Meadowbrook, Queensland, 4131 Phone: 07 3200 4044 Fax: 07 3200 4014 Email: enquiries@supaflow.com.au Web: www.supaflow.com.au Open Weekdays: Monday to Thursday: 7:30am – 4:10pm Friday: 7:30am – 1:10pm

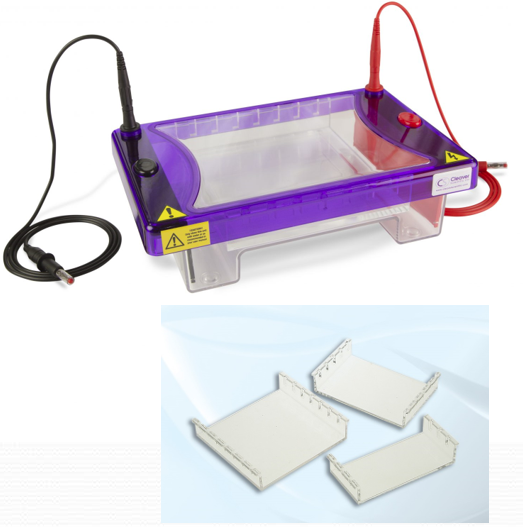

Our moulding and tooling teams can produce any plastic medical device, instrument, or component required—these range from the smallest of widgets to large-scale, complex assemblies. We offer a complete manufacturing process tailored to our medical sector customers’ exact needs and delivered across three shifts working round the clock, five days a week.

Supaflow Engineering is a family owned business based in Meadowbrook, Queensland. Leading Queensland in Plastic Injection Moulding, 3D Product Design and Toolmaking. Supaflow’s reputation for the highest quality moulds and manufacturing is unparalleled with 30 years experience in the industry.

Since its establishment, Supaflow Engineering has worked with businesses of all sizes and produced many different products. Whether you are a small, home business or a large national company – we can facilitate your every need and help your product dreams come to life.

As a leading automated Plastic Injection Moulding company, Supaflow offers only the highest quality production while maintaining their reputation for the most cost effective moulding shop in Brisbane. Supaflow Engineering’s advanced facilities allow it to efficiently provide a range of services to facilitate the entire process from concept design to final plastic injection moulded component production.

Demand for top-quality medical injection moulding components and tools for the medical sector is growing. Innovations and advancements in technology lead to the need for more sophisticated medical tools and devices.

Plastic Injection Moulds can be manufactured for single or multi cavity production, to operate fully automatic or semi automatic machinery. Supaflow Engineering recognises that tooling costs can create a barrier between you and your concepts, which is why we offer toolmaking and moulding in both our Australian workshop and fellow factory in China – manufacturing tools to the highest quality with lower costs.

Our team of highly knowledgeable engineers and manufacturers have honed their skills and sharpened their understanding through close liaison with R&D experts and medical device pioneers to help them learn new ways to deliver medical treatments using the advanced plastic injection moulding techniques that Adreco Plastics has become renowned for.

Using advanced 3D software, Supaflow is able to develop your products and present you with designs both in hard copy and three-dimensionally on a computer screen. Alterations can always be made to your designs prior to any injection moulding or toolmaking occurring, and you can rest assured our design team will take your suggestions and wishes on board.

All our products are designed and manufactured to exacting industry standards and are created using top quality plastics and polymers to ensure premium performance. We have been accredited with ISO 9001 since 2006 and we make it our business to stay up-to-date with all the latest advances in thermoplastic technology. This dedication to quality is reflected in the versatility and durability of our work.

Supaflow Engineering services a large range of industries – including mining, automotive, construction, hardware, storage, window-glazing, plumbing, garage doors and promotional industries. Our design team are experienced to work with any ideas and concepts, and are always eager to expand our horizons.

Supaflow Engineering operates 24 hours a day, with over 15 injection moulding machines with a clamp tonnage of 100 to 450 tons. This gives us the ability to mould items weighing up to 1300 grams precisely and efficiently. Supaflow have processed a variety of materials, including Nylons, Polypropylenes, Polyethylene, Acetal, ABS, Polycarbonates, Styrenes and more.

Adreco Plastics has built up an enviable reputation for quality and durability when it comes to plastic injection moulding for the medical and healthcare sectors. Our products are being used in a wide range of applications in hospitals, clinics, doctors’ surgeries, pharmacies and healthcare settings in the UK and abroad.

To find out how our medical moulding services can help you and your business, or to request a quote for medical tooling and moulding, please get in touch.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly