How and when to manufacturing plastic prototypes - plastic prototype manufacturi

Author:gly Date: 2024-10-15

Injection molding and urethane casting posses unique attributes and applications, shaping the world of production in distinct ways.

Urethane casting, known for its agility in the manufacturing world, brings forth a suite of advantages, particularly when contrasted with the more rigid process of injection molding. These benefits cater to specific needs in production, offering solutions where traditional methods may falter.

This article delves into the depths of these two methods, illuminating their differences, advantages, and applications, guiding you through a detailed comparison to aid in choosing the right technique for your manufacturing needs.

The quality of the surface finish and the aesthetic appeal of the final product are crucial factors in the selection of a manufacturing methods.

Injection molding has carved out a robust niche in the manufacturing world, thanks to its specific advantages, especially when pitted against urethane casting. These benefits span from economic to technical aspects, underpinning its widespread adoption in various industries.

Specialize in CNC machining, 3D printing, urethane casting, rapid tooling, injection molding, metal casting, sheet metal and extrusion

The suitability of injection molding and urethane casting varies significantly with the production volume, influencing the choice between these two methods.

Now, it’s time to provide a clearer understanding of why and when injection molding is the preferred choice over urethane casting, and conversely, where it might fall short.

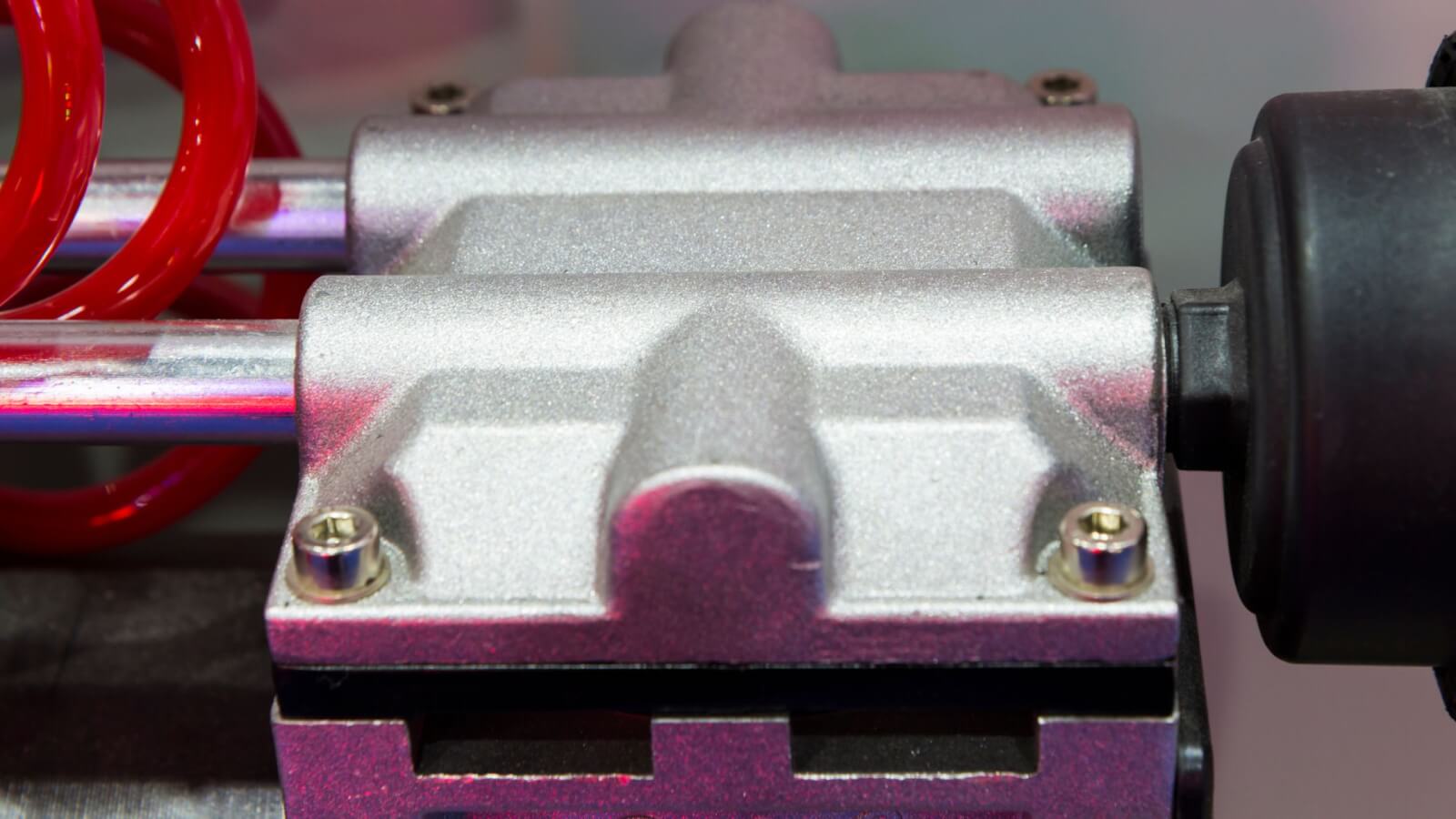

Urethane casting, a cornerstone in the world of rapid prototyping and low-volume production, is a process where urethane resins are cast in liquid silicone molds. This technique is celebrated for its ability to quickly produce parts that closely mimic those made by injection molding, yet with a significantly reduced lead time and tooling cost. It thrives in scenarios where flexibility, material diversity, and intricate designs are paramount.

While urethane casting presents numerous advantages, it also comes with its set of drawbacks, particularly when assessed alongside injection molding. These disadvantages need careful consideration to determine the best manufacturing process for a given application.

At 3ERP, we excel in providing cutting-edge manufacturing services. Our injection molding services include high-quality prototype moldings from rapid tooling in aluminum or soft steel, offering quick turnaround times of as little as 7 days. We handle various challenges, such as tight tolerances, thin walls, and complex geometries, with standard lead times of 7 days for simple parts measuring 0.5 in. x 0.5 in. to 4 in. x 3 in.

The lifespan and maintenance requirements of molds used in injection molding and urethane casting differ considerably, influencing the long-term cost and feasibility of each process.

Tolerances are a critical aspect of any manufacturing process, directly impacting the precision and consistency of the produced parts.

At their core, these manufacturing processes diverge in their approach to material manipulation and end-product creation. Injection molding, a stalwart in the manufacturing realm, excels in high-volume production of plastic parts. It involves the high-pressure injection of molten plastic into rigid, typically metal molds.

In the realm of manufacturing, injection molding stands as a bastion of durable high-volume, high-efficiency production. Primarily used for plastic materials, this process involves injecting molten plastic under high pressure into metal molds. It is a process renowned for its precision, speed, and ability to produce parts with complex geometries and tight tolerances.

In addition, our urethane vacuum casting services are adept at vacuum casting and silicone molding, providing up to 20 parts in 15 days or less, depending on the specifics of the part and volume required. With our expertise in both injection molding and urethane casting, we cater to a wide range of manufacturing needs, ensuring high-quality, cost-efficient, and swift production solutions.

Injection molding and urethane casting, while different in their approach, share common ground in material versatility, the ability to create complex designs, and achieving high-quality surface finishes. The choice between these two processes should be guided by the specific needs of the project, including volume, cost, and the level of detail required.

The concept of undercuts in manufacturing is pivotal, especially when comparing injection molding and urethane casting, as it directly impacts mold design and part ejection.

Understanding the nuances in cost, material selection, and production capabilities is crucial for manufacturers and designers as they navigate the complex decisions inherent in bringing a product to life.

In this section, we will examine the benefits and drawbacks of urethane casting, particularly in its juxtaposition with injection molding, to provide a comprehensive understanding for manufacturers and designers alike.

When comparing the difference in material costs between urethane casting and injection molding, several key factors emerge:

Conversely, urethane casting, a process often allied with flexibility and customization, employs a softer approach. Here, liquid urethane resins are poured into silicone molds, creating parts that benefit from the mold’s elasticity and the resin’s versatile properties.

The cost factor in manufacturing is a multi-faceted consideration, significantly influencing the choice between the injection molding process and urethane casting. Each process has its financial dynamics, shaped by factors like volume, complexity, and material choice.

Injection molding, a method known for its precision and efficiency in mass production of plastic products, contrasts sharply with urethane casting, celebrated for its flexibility and suitability for low-volume production

The size of parts that can be efficiently produced by injection molding and urethane casting varies, highlighting the unique suitability of each process for different project requirements.

The capability needed to achieve specific wall thicknesses is a critical aspect of both injection molding and urethane casting, impacting the strength and functionality of the final product.

The quality of the final product is paramount, and both injection molding and urethane casting have their merits and limitations in this regard.

The lead times for injection molding and urethane casting can vary based on the complexity of the project and the volume of parts required.

The tooling requirements and associated costs for injection molding and urethane casting vary significantly, influencing the choice between these two processes.

Despite its numerous advantages, injection molding also comes with certain limitations, particularly when compared with the flexibility and low-volume efficiency of urethane casting.

Despite their differences, injection molding and urethane casting share some fundamental similarities that make them both valuable in the field of manufacturing:

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly