Hot Runner vs Cold Runner: Exploring the Pros and Cons - cold injection molding

Author:gly Date: 2024-10-15

Discover the countless benefits of partnering with us for all your injection molding manufacturing needs and let us show you why we are the perfect match for your business.

Crescent purchased their new cobot specifically to remove the molded tubs from the mold and place them on conveyor for packaging.

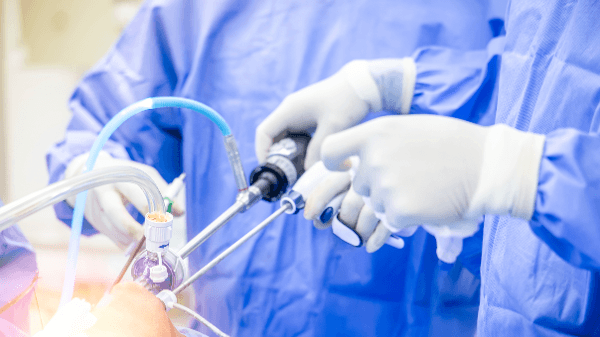

For over half a century, Crescent Industries has been leading the charge in providing top-tier medical injection molding solutions to the ever-evolving medical, pharmaceutical, and dental industries. Starting with diagnostic well plates, we've expanded our expertise to include Class I, II, and III medical devices and components, utilizing a wide range of medical-grade resins. Our state-of-the-art machines, automated quality inspection equipment, and scientifically-backed molding processes guarantee that YOU can rely on our services with confidence. And if that wasn't enough, we offer ISO 7 cleanroom molding, assembly, and packaging services to provide you with a complete solution for your medical products. With complete quality control and inspection, including IQ, OQ, PQ validations, and lot traceability, we uphold the critical medical quality standards required for plastic injection molding medical parts. Trust us to bring your medical device projects to life!

Through UnitedHealthcare, UMR creates and publishes the Machine-Readable Files on behalf of Crescent Industries, Inc. To link to the Machine-Readable Files, please click on the URL provided: https://transparency-in-coverage.uhc.com/

Crescent started by designing and building End-Of-Arm-Tools (EOAT) for each pf the four injection molds. We than use a quick change feature for each EOAT, Allowing easy and accurate switching back and forth during tooling changes.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly