Home | Plastic Injection Molding Solutions - MSi - injection moulding solutions

Author:gly Date: 2024-10-15

The hydraulic press that we have on board is equipped with two large plates. These allow us to accommodate large molds, for example to make sheets.

Why this choice? We have no choice but to add this machine into our production system due to its simplicity of design and use.

Before any use, visually check the mechanical condition. Periodically check the condition of the equipment (see maintenance sheet).

In industry, we often find injection molding systems. This technology is more complex and requires advanced technical knowledge. An injection molding machine allows a high production rate and a precise quality of the produced parts. However, we made the choice of a hydraulic press because it is a machine which is, throughout the world, much more widespread, less expensive; therefore easier to obtain and to use.

The hydraulic press is equipped with two plates, one is fixed and the other is mobile. Actuated by jacks, the movable plate guided by four columns approaches the fixed plate. The cylinders apply even pressure to the element between the plates. The molds installed on the hydraulic press usually consist of two shells (fixed part and moving part) which are strongly pressed. The pressure exerted by the hydraulic press distributes the hot plastic over the entire footprint of the mold.

A work zone around the machine is defined by a marking on the ground. Access near the machine, whilst it is in operation, is permitted only to trained and equipped operators.

The hydraulic press is equipped with a Jobsite Information Sheet which includes all the information necessary for the use of the machine in good safety conditions. It must be positioned in view of all operators using the hydraulic press.

Before carrying out any maintenance, adjustment or repair intervention requiring partial or complete dismantling of parts of the shredder, it is necessary to follow these protocols.

Preventive and corrective maintenance activities must only be carried out by a person trained for this purpose. Each intervention must be recorded in order to keep a history of the maintenance actions carried out.

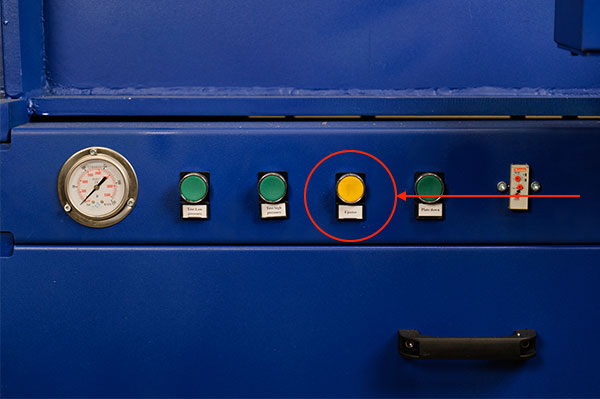

Safety features guarantee the safety of operators on the hydraulic press. Make sure they are correctly installed before use:

The operators who interact with the hydraulic press must be aware of and respect the information relating to the use of the machine, the risks of using the machine, and the appropriate safety practices.

The hydraulic press is a machine for shaping the molten plastic coming out of the Extruder or the Sheet oven. The hot viscous plastic material is placed in a mold fixed to the hydraulic press The jacks that compress it are activated and cause the molds to close. The pressurized plastic spreads around the mold until it cools and the plastic sets.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly