High-precision injection molding - automotive injection molding companies

Author:gly Date: 2024-10-15

(1) Rapid inject mold design time is relatively short, usually can be completed in a few days or weeks. This is because rapid tooling usually uses simplified design and manufacturing processes in order to meet customer needs as quickly as possible.

(1) Ordinary molds usually have higher accuracy and better product quality. Due to its more elaborate design and manufacturing process, ordinary molds are able to produce more accurate and consistent injection molded products.

To sum up, there are some differences between rapid molds and ordinary molds in design, manufacturing and use. The rapid mold has the characteristics of short design time, low manufacturing cost, short life, relatively low precision and quality, and is suitable for small batch production and rapid verification. The ordinary mold has the characteristics of long design time, high manufacturing cost, long life, high precision and high quality, and is suitable for mass production and long-term stable production needs. According to the specific production needs and time requirements, choosing the right mold type can improve production efficiency and product quality.

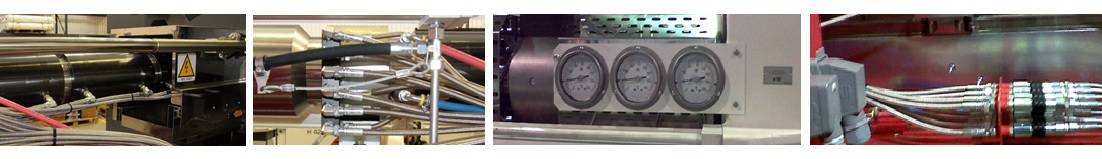

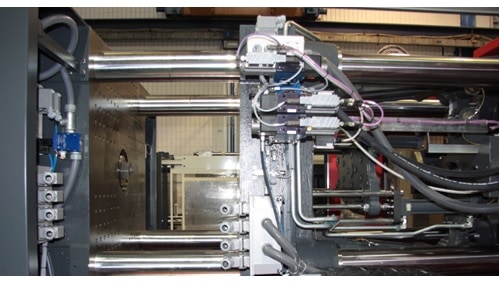

Figure 1. Injection Unit Figure 2 & 3. Thermoregulated screw and distribution Figure 4-7. Thermoregulated barrel and distribution

Thermoset plastics are generally stronger than thermoplastic materials due to the three-dimensional network of bonds (crosslinking), and are also better suited to high-temperature applications. They have high mechanical strength and rigidity and are frequently used to replace metals, reducing the weight by as much as 75%. Thermoset materials are often used in vehicle engine compartments, oil pump and thermostat housings, water inlets & outlets and impellers. Brake linings and disk brake pads can also be manufactured in thermoset plastic.

Negri Bossi provide special applications for thermoset injection molding. This solution includes all the equipment required for reliable and optimal production of high-quality molded parts.

![]()

(1) Rapid tooling is usually suitable for small batch production, sample production and rapid verification needs. Due to its short design and manufacturing time, customers' needs can be met quickly and rapid product development and market validation can be carried out.

(2) In contrast, the design time of ordinary injection molds is longer, which may take weeks or even months to complete, because ordinary molds usually have a more complex structure and higher accuracy requirements.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

(1) Ordinary injection molds usually have longer life and better durability. Due to their more elaborate design and manufacturing process, ordinary molds are usually able to withstand longer use and higher frequency production.

(2) In contrast, rapid molds are usually used for short-term production or small batch production, and their life and durability are relatively low.

(1) The manufacturing cost of rapid inject mold is relatively low. Because its design and manufacturing process is relatively simple, the required materials and processing processes are also less, so the manufacturing cost is low.

(2) However, due to the short design and manufacturing time of rapid mold, there may be certain limitations in terms of accuracy and quality.

(2) Because of the more complex structure and higher precision requirements, the ordinary mold requires more materials and processing technology, so the manufacturing cost is higher.

(2) In contrast, ordinary molds are suitable for mass production and long-term stable production needs, and can meet higher production requirements and longer service life

More details please feel free contact with Industry Prototype-mold Limited (Proto-mold), we can provide you the best price with short lead time at the China prototype -mold manufacture. Miki@proto-mold.com

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly