Gas Assisted Injection Molding: An Innovative Solution for ... - gas assist inje

Author:gly Date: 2024-10-15

Thank you for choosing to make an enquiry with Fuseco. However, due to agreements with our suppliers we are unable to sell outside of Australia and New Zealand.

By using the Sinexcel SVG Power Factor Correction Equipment, the power factor was improved to 0.99, the apparent power required to produce 500kW of real power was reduced to 505KVA, a saving of 120KVA. At 415V 3-phase, this is a reduction in switchboard current to 166A per phase. The installation was being charged on a KVA demand basis, so a tangible saving was achieved. In this case, the KVA demand charge was $8.90/KVA/month, so the following was achieved:

That’s why you need to act now and find a reputable company to outsource your molding needs to. Wunder Mold is one such company. We create durable and long-lasting plastic components and parts using advanced technology, molds, and materials. We listen to your needs and follow your specs to give you the exact product you require. Send us an email at sales@wundermold.com or reach out to us via phone.

These components have to be both decorative and functional, which means the manufacturer has to achieve the balance between aesthetics, usability, and durability. The components you can create through plastic injection molding are so varied it’s difficult to name the most common ones. Some of the frequently used parts are product stops, hooks for pegboards, shelf dividers, but also many more.

Simple PFC solutions incorporate banks of capacitors that work as silent reactive power ‘generators’. These systems were designed many decades ago when electrical environments were a lot simpler than they are today. They are common, very economical and suitable for linear load environments.

Finding solutions with longevity and best performance (max avail ROI) is paramount. Fuseco’s solutions save space & are easy to install.

The Sinexcel Static Var Generator (SVG) provides for the greatest return by maintaining 0.99 lagging (or better) which allows the business to fully utilise the capacity of the supply transformer at all times. The required compensation was calculated to be 303.8kVAr. Fuseco provided three wall-mount SVG modules for installation (1 x 200kVAr, 1 x 100kVAr & 1 x 50kVAr), providing a total compensation capacity of 350kVAr. The wall mounting modules also saved valuable floor space in the company’s switch room.

The merits of power factor correction and solar power were investigated. A solar power solution was not selected as it usually provides benefit for an average of 4 hours a day over the 365 days of a year. This is due to cloud cover, bad weather and night-time which is particularly relevant when the operation is a double shift or 24 hour concern. Whereas power factor correction by using the Sinexcel SVG provides a 24-hour reduction in kVA consumption irrespective of the time of day or night and the weather conditions.

Due to its innate design flexibility, but also high durability and longevity, plastic injection molded parts are very frequently used in the automotive industry. This process makes it easy to design and create various items you find in and on your car every day, such as mirror housings, cup holders, bumpers, but also entire dashboards.

Plastic injection molding is a process so widely used that you can find parts and components made with it in almost any environment and setting. However, this is only one of the amazing facts about plastic injection molding. This manufacturing process is so popular because it offers numerous advantages over other plastic-making methods, and these advantages will only increase with all the current and future trends in plastic injection molding.

Fuseco offers solutions with industry leading reliability & ROI. Money is saved due to superior performance, less maintenance, no capacitor banks plus more.

The PFC units are now installed and running. They are doing a great job at maintaining a constant PF of 0.99 across all phases. Great product and excellent support from both of you. Very pleased doing business with you. Your help has been much appreciated.

Fuseco offers the latest generation of advanced performance PFC solutions that offer instantaneous, dynamic step-less compensation, ideal for the challenging demands of modern electrical environments. The Sinexcel SVG solutions do not need a capacitor bank and offer many advantages due to their compact & modular configuration (including wall-mount options).

Our experts are all pre-eminent leaders in electrical products who provide excellent support in their areas of expertise.

Injection molding various construction and building components is becoming increasingly popular due to the innate versatility of plastic injection molding. There are many reasons why this method is suitable for use in construction:

The most common parts produced with this process include testing kits, surgical preparation products, dental X-ray components, and many more.

What’s more, components for the medical field require various chemical properties, such as high tensile strength, resistance to very high temperatures, and others. Plastic injection molding is suitable for this field of applications because the parts have:

Similarly to the food and beverage industry, plastic parts made for the medical and pharmaceutical field have to follow even more stringent guidelines. In order to meet those standards, manufacturers must use FDA or medical-grade resins and manufacture their components according to ISO certification.

From the moment the AHF and SVG units were turned on our power factor issues were a thing of the past. At both sites our PF is now 0.99 on all phases all the time, the units react instantaneously to our fluctuating load and power factor and the result has been an excellent return on investment.

However, in today’s modern electrical environments, linear loads are not easy to find. Due to the proliferation of LED/energy efficient lighting, switch-mode power supplies, VSD’s, UPS’s, servers/computers and typical appliances, today’s electrical systems experience complex, dynamic non-linear loads. Loads are being switched so fast that the traditional capacitor bank PFC systems struggle to maintain an effective compensation set-point. Therefore, they are perpetually ‘chasing’ the load, either under or over-compensating but rarely providing effective compensation.

Management felt that their electricity costs were too high and they wanted to investigate some options that would reduce their costs and result in a return on investment in under 3 years. As is commonly the case, the peak kVA Demand occurs during a combination of full production and office air-conditioning during the warmer months (Dec, Jan & Feb). Even if this peak kVA demand is only needed for 15 minutes, it becomes the peak kVA charge for the month (according to this particular billing contract used by their supply authority). Therefore, the company was still charged the maximum amount even in a very low load month. The challenge here was to find a way of saving money by lowering the peak kVA.

We inform about the latest reliable PFC solutions, assist with compliance to specifications, space considerations & advise on maximum available ROI.

Some of the most commonly-produced elements in the construction industry include small and large accessories, fasteners, and various hand tools.

Parts used in the food and beverage field must follow stringent health and safety rules and regulations, such as the GMA-safe program and FDA certification. All this is necessary to ensure the wellbeing of individuals using such products. To abide by the aforementioned standards, molded parts have to be BPA-free and completely non-toxic.

Analysis revealed that the site had a ‘real’ (kW) demand for electrical energy of 500kW and a power factor of 0.8. Power factor is expressed as kW/KVA, so the ‘apparent’ power required to produce this ‘real’ power was 500/0.8 = 625KVA. Improving the power factor will reduce this KVA and therefore reduce the supply transformer requirements or increase the available ‘real’ power from the transformer.

That’s why it’s important to choose the right resins and materials to produce those elements that will be used in this industry. The most commonly-manufactured parts for this industry are:

Plastic injection molding has a crucial role in development and manufacturing of numerous products and components, from airplane components to consumer toys and electronics. Here are the most common applications of parts created through this process:

An injection moulding business based in Brisbane engaged Fuseco to investigate ways to reduce the cost of their electricity expenditure. Their operation is a good example of a dynamic medium sized engineering facility. After conducting a site visit and analysing their power quality, it became apparent that correcting their power factor would yield significant savings. A saving of over $1,000 per month was achieved!

An injection moulding business based in Brisbane engaged Fuseco to investigate ways to reduce the cost of their electricity expenditure. Their operation is a good example of a dynamic medium sized engineering facility. After conducting a site visit and analysing their power quality, it became apparent that correcting their power factor would yield significant savings. A saving of over $1,000 per month was achieved!

Our PFC solutions are modular & compact, fitting into existing spaces. Industry leading ROI is achieved by high performance and low maintenance costs due to new technology replacing capacitor banks.

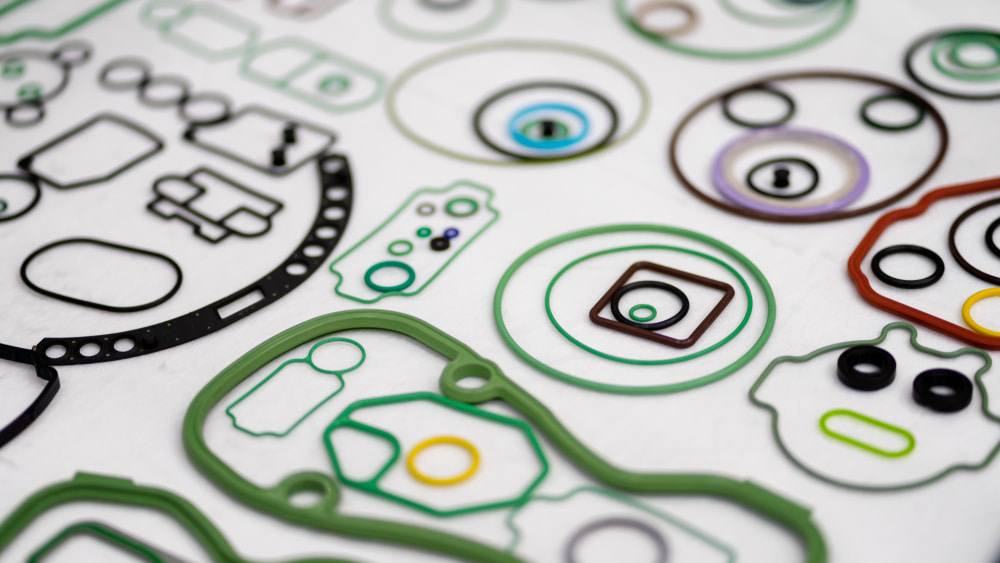

Plastic injection molding is an extremely versatile manufacturing process, meaning the components it produces come in all shapes, sizes, and intricacies. This makes this process very popular and widespread across many applications and industries. The parts made through partnership with a plastic injection molding company near you are strong, durable, long-lasting, and suitable for different uses, some of them more frequent than others.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly