DIY rapid injection molding - General Discussion - injection molding at home

Author:gly Date: 2024-10-15

Several factors can affect the efficiency and quality of short run plastic injection molding, including machine and mold design, material selection, operator skill and training, and maintenance and calibration.

Consistent process control: Consistent process control can help ensure that each part produced meets the desired quality standards. This includes monitoring key process parameters, such as temperature, pressure, and cycle time, and making adjustments as needed.

Quality control measures are essential for ensuring that each part produced meets the desired quality standards. Examples of quality control measures in short run plastic injection molding include visual inspection, dimensional inspection, functional testing, and statistical process control. Quality control measures help identify defects and ensure that each part meets the desired quality standards.

Article Original From: https://www.djmolding.com/maximizing-efficiency-and-quality-in-short-run-plastic-injection-molding/

3D printing or additive manufacturing refers to the process where the material is built layer by layer. 3D printing creates 3D objects by slicing a computer aided design (CAD) file into layers to reproduce the physical part using filament or powder material. Contrary to popular belief, filament based 3D printing (Fused deposition modeling FDM or Fused filament fabrication FFF) is not the same as powder bed fusion 3D printing such as selective laser sintering (SLS) or Multijet fusion (MJF). FDM parts tend to require support structures, have uneven strength in some directions, has a strong layering effect which could result in shear failure (separation) and the nozzle tends to limit precision. This limits FDM printers to low strength rapid prototyping. Common plastic filament material includes ABS, PLA and PET.

There is a misconception in the manufacturing world that 3D printing is going to replace injection moulding, especially with the proliferation of 3D printing technologies in recent years. Injection moulding is still used in the majority of plastic parts for industry due to the familiarity of quality and process as well as speed for mass production.

Proper material selection and handling: Proper material selection and handling can help ensure that the final product meets the desired properties and characteristics. This includes selecting the right material for the specific application and ensuring that the material is properly handled and prepared before injection.

The good news is, at Additive Engineering, we offer injection moulding, vacuum casting, metal and plastic 3D printing services with a range of 3D printer options and an experienced team to support you.

Enable quick, uniform cooling of the ejector pin's unique shape.Results : Hot spot eliminated at contoured pin with tiny cooling channels. Ideal for cooling large surfaces 0.6-0.8mm from contour, helix-shape channel maximised part strength.

Efficient mold design and tooling: Efficient mold design and tooling can help reduce cycle times, minimize waste, and improve part quality. This includes optimizing the mold design for the specific part and using high-quality tooling materials.

To maximize efficiency in short run plastic injection molding, several best practices can be implemented, including proper machine setup and operation, efficient mold design and tooling, material handling and preparation, and process monitoring and optimization.

To compare both manufacturing processes, the following overview recaps pros and cons of injection moulding and 3D printing.

On the other hand, a SLS 3D printed part can be used as an end use product, made by precise sintering layers of nylon powder with the use of powerful lasers, without the need for support structures. Such high performance 3D printing machines tend to cost more.

For more about maximizing efficiency and quality in short run plastic injection molding,you can pay a visit to Djmolding at https://www.djmolding.com/low-volume-manufacturing-service/ for more info.

Small, unique cooling channels inside the mould of a bucket lid insert allow for parallel cooling of small geometries not possible with other methods. Results : Faster heat transfers due to short channels. Uniform cooling of material, maintained properties

Machine and mold design: The design of the machine and mold can significantly impact the efficiency and quality of the process. A poorly designed machine or mold can lead to longer cycle times, increased waste, and lower quality parts.

Rather than seeing 3D printing as a potential replacement for injection moulding, these two manufacturing technologies can be complementary and used together to improve quality of plastic products, shorten pre-production cycles, take advantage of mass customisation to cater to more product variants before moving onto large batch production.

Continuous improvement and problem-solving: Continuous improvement and problem-solving can help identify areas for improvement and prevent quality issues from occurring in the future. This includes using tools such as root cause analysis and corrective action to address quality issues and improve the process.

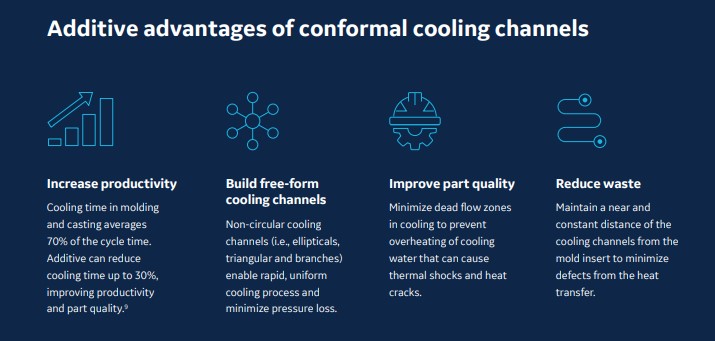

An Industrial moulding company utilised metal 3D printing (Direct metal laser melting) technology to 3D print a mould core with conformal cooling channels. The core contained eight independent, internal conformal cooling channel at 5-8mm in diameter. 3D printing lends design freedom for a more efficient heat exchange and imcrease the overall injection moulding process’ productivity through decreased cooling cycle time, defects and improved the injected plastic parts’ aesthetics.

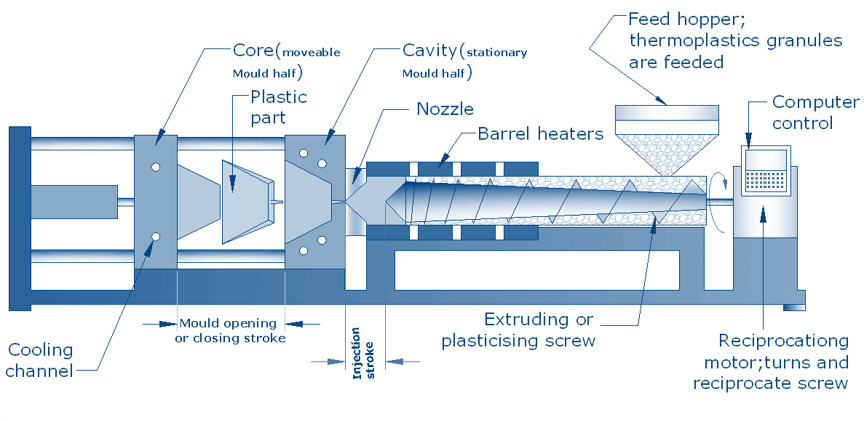

Injection moulding makes use of moulds or dies. The part design is used to create the inverse in split-die tooling, the tooling cavity is traditionally referred to as female die and the other as the male. These dies are commonly CNC machined out of metal material such as aluminium or tool steel that can handle molten material. Molten material is poured into the mould via an injection method and the moulds are cooled to release complete plastic parts. There is also metal injection moulding, although the following will focus on plastics.

Efficiency refers to the ability to produce a high volume of parts in a short amount of time while minimizing waste and costs. Quality, on the other hand, refers to the ability to produce parts that meet or exceed customer expectations in terms of functionality, durability, and aesthetics. In short run plastic injection molding, it is essential to balance both factors to achieve successful production. If the process is not efficient, it can lead to increased costs, longer lead times, and lower profitability. If the quality is not up to par, it can result in customer dissatisfaction, product recalls, and damage to the company’s reputation.

All manufacturing methods have their own strengths and disadvantages and which process to use depends on what requirement is a priority. In some cases, metal 3D printing could even manufacture inserts and complex injection moulded tools with conformal cooling chambers to improve traditionally injection moulded products.

Injection moulding and additive manufacturing / 3D printing are often used as manufacturing techniques for plastic parts such as drink bottles, lids, caps, covers, housings, brackets, packaging, car parts and toys.

Anyone can access multiple plastic and metal 3D printing processes with the use of Additive Engineering’s 3D printing service, 3D printing material and expertise.

Emerging technologies and trends in short run plastic injection molding can significantly improve efficiency and quality. Examples of future trends in the industry include 3D printing, advanced materials, and smart manufacturing. These trends have the potential to reduce cycle times, minimize waste, and improve part quality.

The 3D printing process for manufacturing works best with low volumes, when it is difficult to justify tooling costs. 3D printing parts including prototypes help the customer’s decision making process and has less cost implications with modifications as compared to the traditional injection molding process.

Proper machine setup and operation: Proper machine setup and operation can significantly impact the efficiency of the process. This includes setting the correct parameters, such as temperature, pressure, and cycle time, and ensuring that the machine is running at optimal conditions.

Process monitoring and optimization: Process monitoring and optimization can help identify inefficiencies and areas for improvement. This includes using sensors and monitoring systems to track key process parameters and making adjustments to optimize the process.

Automation and robotics can significantly improve the efficiency and quality of short run plastic injection molding. Automated systems can help reduce cycle times, minimize waste, and improve part quality. Examples of automated and robotic systems in short run plastic injection molding include robotic part removal, automated material handling, and automated inspection and testing.

Maintenance and calibration: Regular maintenance and calibration of the machine and mold are essential for ensuring consistent quality and efficiency. Neglecting maintenance and calibration can lead to machine breakdowns, longer lead times, and lower quality parts.

Cooling channels form a mesh structure to enable uniform surface cooling of a glass insert for spectacles, just 2-3mm beneath mould contour. Results : High-pressure stability throughout arched structure and temp control across large areas

To improve quality in short run plastic injection molding, several tips can be implemented, including consistent process control, proper material selection and handling, quality inspection and testing, and continuous improvement and problem-solving.

Are you tired of sacrificing quality for efficiency in your short run plastic injection molding processes? Well, it’s time to put an end to that. Maximizing efficiency and quality is not only attainable, but it’s imperative for the success and growth of your business. In this blog post, we’ll explore the strategies and techniques that can help you achieve both efficiency and quality in your short run plastic injection molding. So, get ready to take your plastic injection molding processes to the next level!

Metal 3D printing can also be used as a manufacturing method to 3D print injection moulds. This is one of the latest innovations in established 3D printer markets such as the US and is a game changer for the plastic injection moulding manufacturers, especially when cnc machining is most commonly used in manufacturing molds in injection molding. 3D printed free-form cooling chambers has considerably reduced cooling time over machined straight channels by lowering polymer and cavity surface temperatures. 3D printed inserts for injection molded tools is another quick way to for custom injection moulding and modify before committing to production tooling. Quicker cycles increase productivity, more variants and more uniform cooling improves part quality and minimises defects from heat transfer. Not all 3D printer for metal is alike, ask us which is best suited for your requirements in precision and manufacturing conditions.

Material selection: The selection of the right material is crucial for achieving the desired properties and characteristics of the final product. Choosing the wrong material can result in poor quality parts, increased waste, and longer lead times.

With the high initial cost set up and time-consuming nature of injection moulding tooling design, 3D printing is more accessible for prototyping and testing of design before tooling commitments. The cost of modifications in injection moulding is high unless metal 3D printed inserts are considered, or the use of 3D printed conductive metal to improve heat dissipation in concentrated areas and 3D printing of injection moulds with conformal cooling chambers.

First of all, is it injection moulding or injection molding? Injection moulding originates in Britain and is often used in Australia and Canada while injection molding is the American spelling. Since Additive Engineering is based in Australia, we use injection moulding to answer enquiries about injection molded parts, mold cavity, injection molder, manufacture of injection mold, plastic injection molding, 3D printed injection molds / printed molds and an injection molding machine.

Operator skill and training: The skill and training of the operator can also impact the efficiency and quality of the process. An inexperienced or poorly trained operator can lead to longer cycle times, increased waste, and lower quality parts.

Other plastics 3D printing include Stereolithography (SLA) and Material jetting such as Polyjet 3D printing. SLA technologies is typically used in high precision and low cost single use parts.

Is it the case of injection moulding vs 3D printing? How does one choose which manufacturing process is better suited? Why not both? When starting a project involving plastic manufacturing, the factors to consider include material properties, process’s flexibility to design change, precision, finish, volumes, time and cost.

Material handling and preparation: Proper material handling and preparation can help reduce waste and improve efficiency. This includes using the correct material handling equipment, such as drying ovens and material feeders, and ensuring that the material is properly prepared before injection.

In conclusion, balancing efficiency and quality is crucial for successful short run plastic injection molding. Factors that affect efficiency and quality include machine and mold design, material selection, operator skill and training, and maintenance and calibration. Best practices for maximizing efficiency include proper machine setup and operation, efficient mold design and tooling, material handling and preparation, and process monitoring and optimization.

3D printing is great for batch production of less than 1000 parts, suitable for complex part that may require mass customisation, frequent design changes and can be used for creating a 3D printed mold. Injection moulding, on the other hand, is better for bulk production in the thousands of simple designs.

Quality inspection and testing: Quality inspection and testing can help identify defects and ensure that each part meets the desired quality standards. This includes using visual inspection, dimensional inspection, and functional testing to verify the quality of each part.

Whatever you are most familiar with, whether it is ‘printing vs injection molding’, interests in ‘3D printed injection mold’, if you have an plastic part project, additive manufacturing enquiries or past experiences with different 3D systems, we like to hear from you.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly