Dip Moulding Materials - electrical pvc moulding

Author:gly Date: 2024-10-15

The corroded metal material is iron. Common corrosive plastics include: flame-retardant plastics, acidic plastics, PVC plastics, etc. After the screw, melt barrel and flange are corroded, some pits are formed on the surface, and the surface is rough, which makes the flow resistance of the melt when the injection molding machine works. Some materials are easy to adhere to the surface, causing decomposition and carbonization. Severe corrosion will increase the gap between the screw and the melt barrel, increase the leakage, and reduce the injection efficiency.

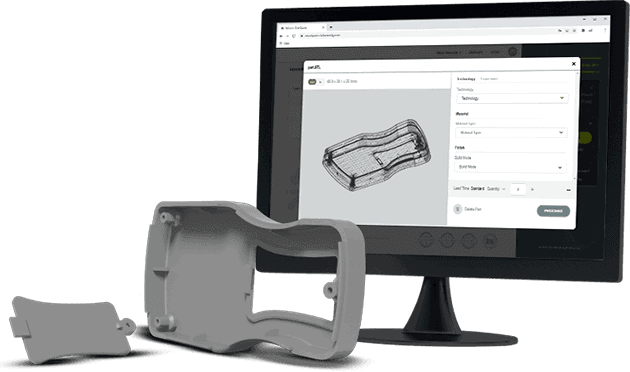

If you’re looking for an injection molding company who can support your business needs, you should turn to ICOMold. ICOMold offers low prices on plastic injection molds and plastic parts. You can also get an instant injection mold quote and CNC manufacturing parts quotes through our online quoting and project management system. We offer fast and dependable injection mold services and trouble-free injection mold modifications. Our services include low and high-volume production molds and parts— rapid prototype injection molds, production molds, and export molds. Get a plastic injection molding quote today.

It’s true that there are several plastic mold makers to choose from. Learn why ICOMold is the right plastic mold maker for you and your project.

Generally speaking, the following aspects affect the service life of the plasticizing system of the injection molding machine:

Whether it is a flame-retardant plastic or an acid glue, the plastic will decompose acid gas when it is processed at high temperatures, and the plastic melt is easily carbonized and sticks to the metal. Therefore, on the one hand, the plasticized components should be made of stainless steel or surface chrome plating; on the other hand, low back pressure, low temperature and low shear processes should be used as much as possible in the production and processing to reduce the degradation of the plastic;

Injection molding is the process of producing various parts by injecting heated material into a mold. Injection molding can be done with many different materials such as metals, glasses, elastomers, confections, and most commonly thermoplastic and thermosetting polymers. ICOMold specializes in custom plastic injection molding, CNC machining of plastic and metal, and urethane casting. Get a CNC quote or a plastic injection molding quote today!

ICOMold’s fast-turn, low-cost, high-value injection molding enhanced by joining Fathom’s manufacturing platform. Learn More

(3) Cold start is a kind of anxious psychology and irresponsible work attitude. When the temperature of the sol cylinder has not reached the set required temperature or has just reached, the residual material in the barrel absorbs the heat from the heating ring to make the temperature higher, while the temperature of the inner layer is still very low, so when cold start The screw torque is very large, causing stress fatigue on the screw. In severe cases, the screw will be twisted quickly, and the rubber head and rubber ring will be twisted. Most of the metal impurities entering the sol cylinder are brought in with the crushed material.

Plastic mold manufacturing is the process of creating molds to mass product plastic parts. Learn more about plastic mold manufacturing.

At the same time, because the viscosity of the plastic melt is very high at this time, the injection pressure and injection speed must be increased to carry out the injection molding process, which increases the impact and load of the three small parts, and accelerates their wear and stress fracture.

Finding the right company for your injection molding project does require careful research and consideration. Read about ICOMold, one of the leading plastic injection molding companies, and their process for delivering high-quality parts, fast at low prices.

Some modified plastics are added with minerals, glass fiber, metal powder, etc. The existence of these materials will cause uniform mechanical wear on the screw, three small parts and the melt barrel during the plasticization and injection processing. The nitrided layer and chromium-plated layer can be polished off. After abrasion, the gap between the screw and the melt barrel is increased, which reduces the plasticizing effect, increases the leakage of the injection, reduces the injection efficiency, and reduces the processing accuracy.

(1) When metal impurities are mixed in the plastic and enter the melt barrel together, due to the extrusion effect, the screw edges, grooves, rubber rings, rubber gaskets of the screw will be worn to different degrees, resulting in unstable and easy injection molding. Produce black spots and black streaks;

If you are looking for a plastic molder near you, no sweat. ICOMold can service customers just about anywhere. Learn more about ICOMold.

Therefore, in order to minimize wear and extend the service life of plasticized components, the temperature should be appropriately increased during processing and the screw speed should be reduced. The use of chrome plating or bimetallic solutions can more effectively prevent abrasion.

(2) The wrong plastic is artificially added, and high-temperature plastic is added to the melt barrel set to low temperature, which causes excessive torque of the screw during the sol, and stress fatigue of the screw;

The adjusters habitually set low-temperature work and habitually set high-speed and high-pressure work, which gradually degrades the performance of the plasticized components. For example, when processing PC and PA plastics, when the temperature does not meet the requirements, the viscosity of the plastic is very large. If the sol action is forced at this time, the sol pressure and the sol torque must be increased, thus increasing the stress fatigue of the screw.

Therefore, to ensure that the injection molding machine is always in good condition, it is necessary to clarify the performance of the injection molding machine used, understand the performance and quality of the plastic materials used, and strengthen the management of the use of the injection molding machine to reduce failure rates, reduce maintenance costs, and extend The purpose of service life.

Plasticized components of the injection molding machine, here refers to: screw, melt barrel, rubber head, rubber ring, rubber gasket. When the injection molding machine is working, the plasticized components are like the wheels of a motor vehicle. As long as they are started, they will be subjected to pressure, impact, friction, and squeeze. For the same tire, driving on a flat road and operating by a skilled driver can often prolong the service life of the tire. And when driving on uneven roads with lots of sand and gravel, coupled with frequent emergency braking actions, the pattern on the tire surface is quickly polished and scrapped.

This aspect is also very important. If the assembly of the sol barrel is not tight enough, the screw will touch the sol barrel when the sol or glue is injected, causing the screw or the sol barrel to wear. Therefore, the technical status of the equipment should be checked regularly, and attention should be paid to the abnormal phenomenon of the parts in the process.

Overmolding is the process of taking a part and then using plastic injection molding to add additional layers over the current part.

In the third aspect, due to the thermal sensitivity of the above plastics, too high temperature or too long heating time, it is easy to decompose, degrade and carbonize the plastics. Therefore, the production process should avoid and reduce artificial shutdowns. If you need to stop the machine, you should lower the temperature first, close the material gate, and after the melt in the sol tube is finished, switch to PP or PS to clean the sol tube before stopping the machine.

Therefore, the breakage of the blade of the crusher should be checked frequently, and the blade should be replaced immediately if it is found to be worn. On the other hand, check and clean the magnets in the blanking hopper frequently. When the metal scraps adsorbed around the magnet are saturated, the adsorption force for the iron scraps on the outer layer will be weakened. Even if it is attracted, it will be easily washed away by the continuously flowing plastic and enter the sol cylinder together.

(1) Long-term use of high back pressure sol can accelerate the wear of the three small plasticized parts. This situation generally occurs when toner is used. Since the toner is difficult to disperse, the method of increasing the back pressure is adopted.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly