D706 Standard Specification for Cellulose Acetate Molding ... - cellulose acetat

Author:gly Date: 2024-10-15

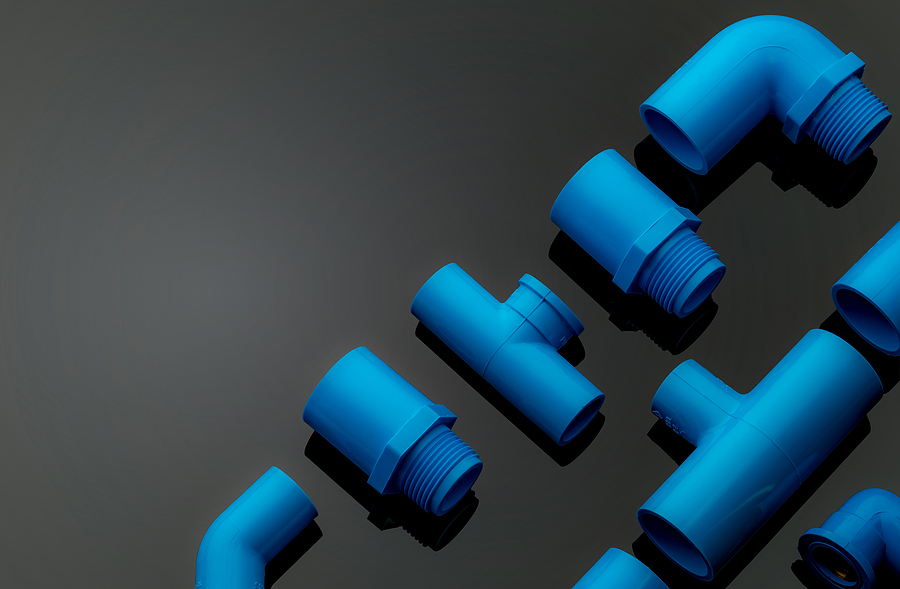

Once the mold material is chosen, it’s time to move onto what you’ll use for plastic. Generally, thermoplastic resins can be used. Overall, the type of plastic will play a major factor in how much money you’ll be spending per mold produced. And, the plastic resin choice you make will play a large role in carrying out the functions of the parts being made.

Custom plastic injection molder based in San Diego County, California. Since we were established in 1978, we have had one mission: To produce the finest parts, at the lowest prices.

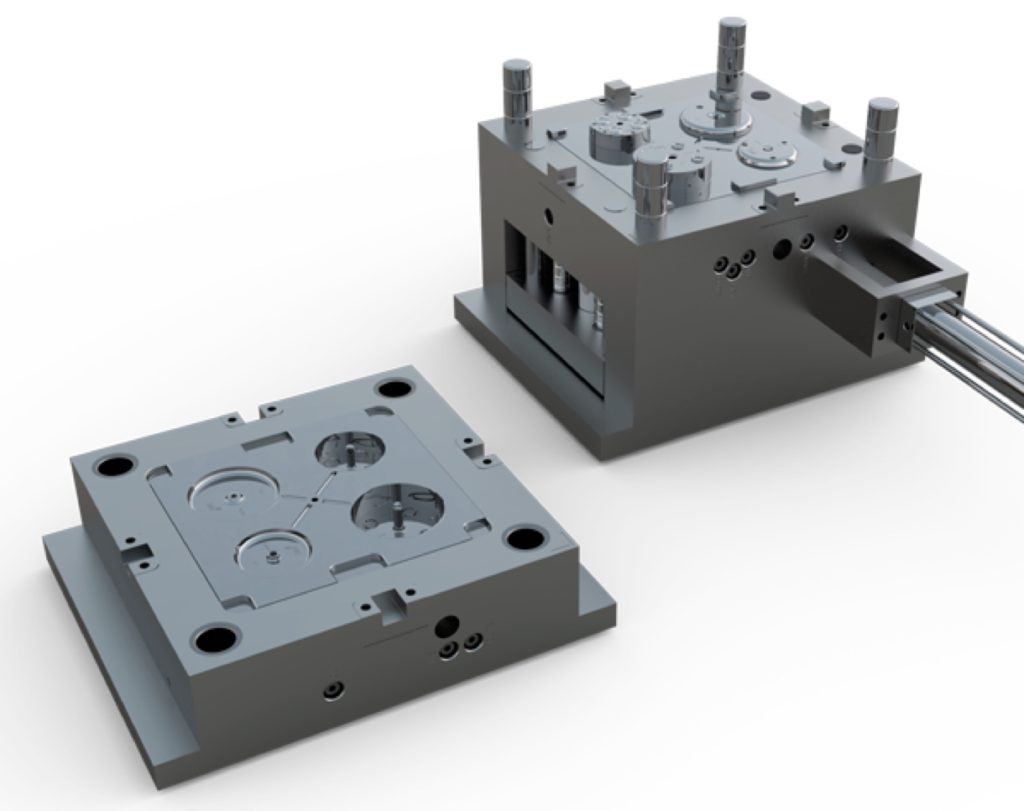

Oftentimes, people looking to operate through plastic injection molding processes miss one key factor: The molds are almost always made out of steel or aluminum, not plastic.

Most of the above bulleted points are specific, holding special qualities within. If your manufactured part does not need any special qualities, you may be able to get away with even cheaper plastic resin to save your company even more money in the long run.

The plastic injection molding process involves heating plastic (in pellet or grain form) until it has melted. The molten material is then injected into a closed two-part mold under high pressure, where it cools and solidifies. Once the material has fully hardened, it maintains the shape of the mold cavity. At this point, the mold can be opened so the piece can be removed and sent for further processing as needed.

Deciphering the cost of a plastic injection mold is not super easy; it’s actually quite complex. You see, one specific plastic injection mold can range anywhere from $3,000 to $100,000, sometimes even more. Simple molds range from $3,000 to $6,000 and larger molds usually start at $25,000 and can work their way up from that point depending on the details involved.

The following article provides an overview of plastic injection molding. It highlights what the process entails, key advantages of using it over other manufacturing methods, and challenges faced when conducting injection molding operations.

A final pro and con to walk away with is that aluminum molds can typically wear down quickly, and once worn, they cannot be repaired or modified. On the other hand, steel can be easily modified through welding processes to change the design or make repairs. Again, steel is much pricier than aluminum.

Because the price has such a wide range, we highly suggest weighing the pros and cons to a plastic injection mold investment. To do this, you’ll want to determine whether or not you’ll be producing enough parts to break even and one day start making money. The higher the volume numbers are the lower the per-piece cost will be, resulting in much more profit the longer you intend to stick to the same manufacturing process.

Generally, plastic resins can range from $2 to $20 per pound. The pieces needed [or pounds used] in each injection will ultimately depend on the size of the mold and how detailed/complex it is. Some of the descriptions you’ll want to look for when purchasing plastic resins are as followed, again, dependant on what you want your manufactured pieces to do:

While injection molding offers a number of advantages over other manufacturing methods, it also comes with some challenges, such as:

The only downside to using aluminum is that durability is not its strongest marker. That’s what steel excels in, and though it does weigh in on the more expensive side, steel will definitely last longer and ultimately lower the price-per-piece in the long run [if you’re looking to mass produce].

To provide you with an initial positive, we’d like to state a somewhat obvious consideration. If you will break even and start making profit along the way, purchasing a plastic injection mold is worth it. Why? Because it’s the fastest, most economical solution to produce plastic parts in bulk – and the solution is not all that difficult to learn and train others to follow through with.

The #1 cost associated with injection moldings pertains to the machining process, but there are several factors that can weigh in. Examples include:

Aluminum is a far better option than steel, primarily because it dissipates heat better, but also because it’s more cost effective. Why does dissipation of heat matter? Because it’ll cut cycle time down and promote efficiency.

The injection molding process can be used to produce parts and products for various industries. At Paulson Manufacturing, we leverage the technology to make high-quality, dependable safety equipment for industrial workers and fire responders. By carefully designing and building our own molds, we ensure we create solutions that surpass even the most rigorous safety standards. To learn more about injection molding in general or our capabilities, contact us today.

There are many benefits to using injection molding over other manufacturing methods to produce plastic components. For example:

Many industries use injection molding to produce their parts and products. The process enables them to create components of various shapes and sizes in high quantities (i.e., thousands or millions of pieces) quickly, consistently, and cost-effectively. While it can be used with a variety of other materials (e.g., glass, metal, and rubber), it is most commonly utilized for plastic. For example, clear plastic is often injection molded to form personal protective equipment (PPE), such as face shields and goggles, for industry professionals.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly