Custom Plastic Injection Molding | Order Parts Online - plastic molding 1 2

Author:gly Date: 2024-10-15

ABS, known for its high impact strength and mechanical robustness, is the material of choice for consumer goods, automotive parts, and electronic housings.

Feature papers represent the most advanced research with significant potential for high impact in the field. A Feature Paper should be a substantial original Article that involves several techniques or approaches, provides an outlook for future research directions and describes possible research applications.

Technically, ASA not only retains the main properties of ABS but also incorporates the weather resistance advantages of PMMA plastic, extending its application to outdoor uses.

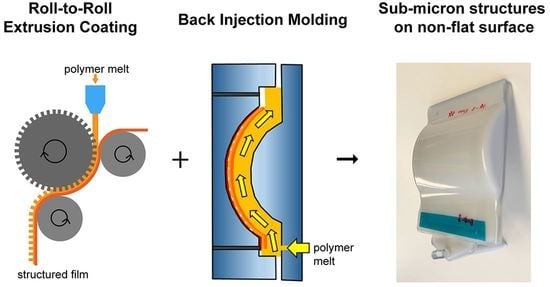

Xie, S.; Werder, J.; Schift, H. Back Injection Molding of Sub-Micron Scale Structures on Roll-to-Roll Extrusion Coated Films. Polymers 2021, 13, 1410. https://doi.org/10.3390/polym13091410

Xie S, Werder J, Schift H. Back Injection Molding of Sub-Micron Scale Structures on Roll-to-Roll Extrusion Coated Films. Polymers. 2021; 13(9):1410. https://doi.org/10.3390/polym13091410

In the following content, we will delve into the performance of these two materials and comprehensively evaluate their performance in specific application scenarios.

Its electrical insulation properties also make it attractive for those looking to manufacture casings for electrical components, as well as automotive parts like dashboards or bumpers.

In additive manufacturing, its other common uses include prototyping, gears, and even tools, as it offers better resistance to physical stress than some other common 3D printing polymers.

ACIS®, Autodesk Inventor®, CATIA® V5,Creo™ Parametric, IGES, Parasolid®, Pro/ENGINEER®,Siemens PLM Software’s NX™, SolidEdge®, SolidWorks®, STEP

Additionally, ABS’s composition allows it to be recycled, reducing its environmental impact compared to materials that cannot be easily processed for reuse.

Feature papers are submitted upon individual invitation or recommendation by the scientific editors and must receive positive feedback from the reviewers.

On the other hand, ASA boasts strong UV and impact resistance, making it suitable for various outdoor installations such as signage, sports equipment, and automotive exterior applications.

However, the major drawback of ABS is the intense fumes produced during printing, accompanied by issues like warping, hence it’s recommended to print in well-ventilated areas.

In terms of heat resistance, ASA and ABS are relatively similar, with ABS having a heat distortion temperature of 93~118°C and still displaying some toughness at -40°C.

All articles published by MDPI are made immediately available worldwide under an open access license. No special permission is required to reuse all or part of the article published by MDPI, including figures and tables. For articles published under an open access Creative Common CC BY license, any part of the article may be reused without permission provided that the original article is clearly cited. For more information, please refer to https://www.mdpi.com/openaccess.

ASA contains modifiers in its composition that enhance its resistance to UV-induced fading and yellowing, making it more suitable for applications where long-term aesthetic appeal is important.

Compared to ABS, ASA significantly improves weather resistance by substituting butadiene rubber with acrylate rubber, which lacks double bonds.

As the application scope of ASA and ABS continues to expand, concerns about safety hazards in plastic products have arisen: Is ASA toxic? Is ABS safe?

Outstanding UV resistance and anti-aging capabilities mark a significant advantage of ASA and represent one of its largest differences from ABS plastic.

Xie, Sijia, Jerome Werder, and Helmut Schift. 2021. "Back Injection Molding of Sub-Micron Scale Structures on Roll-to-Roll Extrusion Coated Films" Polymers 13, no. 9: 1410. https://doi.org/10.3390/polym13091410

Yet, printing with ASA typically demands higher extrusion temperatures, and it is pricier compared to ABS, necessitating a balance between cost and application needs when selecting plastic materials.

The substitution of rubber double bonds plays a pivotal role in defining the subtle yet significant differences in performance between ASA and ABS.

ASA shares these strengths but stands out for its enhanced toughness and better integrity under UV exposure, especially in outdoor settings.

The acetone smoothing method, known for achieving a high-gloss surface effect on ABS, is equally applicable to ASA materials. ASA injection molding products do not require painting, plating, or other surface protection and can be used outdoors directly.

Despite its lower UV and weather resistance compared to ASA, ABS remains a popular choice for indoor applications where these factors are less critical, and its use continues to be supported by ongoing research and improvements in plastic formulation and processing techniques to enhance its safety profile.

ASA’s fire resistance is about ten times higher than that of ABS, with a fire rating of B1 level, meeting the basic fire protection requirements for residential housing, which ABS does not achieve.

ABS has been noted to emit styrene during printing, a VOC with potential health risks in poorly ventilated spaces, while ASA is often regarded as having a less intense odor but still requires proper safety measures.

While both materials have the drawback of emitting fumes during processing, especially in 3D printing, this issue can be mitigated with appropriate safety measures.

ABS is celebrated for its robust mechanical strength and stiffness, making it suitable for durable products, alongside notable impact resistance, even in cold environments.

Xie, S.; Werder, J.; Schift, H. Back Injection Molding of Sub-Micron Scale Structures on Roll-to-Roll Extrusion Coated Films. Polymers 2021, 13, 1410. https://doi.org/10.3390/polym13091410

Due to its unique structure, ASA offers similar chemical resistance to ABS but with better weatherability and UV resistance, which can translate into better long-term performance and safety in outdoor applications.

This comparison highlights the key differences between ASA and ABS; for more insights into plastic materials, stay tuned to FOWMOULD!

ABS plastic is a terpolymer made from acrylonitrile (A), butadiene (B), and styrene (S), combining the properties of PB, PAN, and PS to create a material with a balanced set of mechanical characteristics that are tough, hard, and rigid.

In terms of health and environmental safety, ABS does not contain any known carcinogens and is generally considered non-toxic when it is in its solid form.

Editor’s Choice articles are based on recommendations by the scientific editors of MDPI journals from around the world. Editors select a small number of articles recently published in the journal that they believe will be particularly interesting to readers, or important in the respective research area. The aim is to provide a snapshot of some of the most exciting work published in the various research areas of the journal.

Xie, Sijia, Jerome Werder, and Helmut Schift. 2021. "Back Injection Molding of Sub-Micron Scale Structures on Roll-to-Roll Extrusion Coated Films" Polymers 13, no. 9: 1410. https://doi.org/10.3390/polym13091410

ASA can withstand degradation, aging, and fading caused by UV exposure, while also offering robust protection against decomposition or discoloration due to oxidation in the atmosphere and high temperatures during processing.

ASA is renowned for its outstanding weatherability and UV resistance, making it highly suitable for outdoor use where it can maintain its color and physical properties over extended exposure to natural elements.

As we’ve mentioned, one of the main attractions of ABS is its technical nature, which tends to steer its applications towards industrial uses.

ABS and ASA both exhibit good thermal stability during processing, but ASA’s enhanced resistance to UV light can translate to better long-term thermal stability in outdoor applications.

Therefore, it is recommended to use ABS in well-ventilated areas and follow safety guidelines to minimize exposure to these emissions.

Additionally, for general purposes, it can be found in home appliances, hulls, decorative items, toys, and the renowned LEGO bricks.

Overall, both ASA and ABS are versatile thermoplastic polymers that, despite their similarities, possess unique characteristics to meet different application needs.

Xie S, Werder J, Schift H. Back Injection Molding of Sub-Micron Scale Structures on Roll-to-Roll Extrusion Coated Films. Polymers. 2021; 13(9):1410. https://doi.org/10.3390/polym13091410

ZIP-Document (ZIP, 362 KiB)

Abstract: Roll-to-roll extrusion coated films were bonded onto polymer parts by back injection molding (BIM). The polypropylene (PP) coated polyethylene terephthalate (PET) films were pre-patterned with microstructured V-shaped grooves with 3.2 µm and 53 µm width, and other geometries. Bonding on PET and poly(methyl methacrylate) (PMMA) parts was facilitated by either higher tool or melt temperatures but was particularly enhanced by applying a mild oxygen plasma to the backside of the PET film prior to injection of the polymer melt. Silver wires from conductive nanoparticle ink were embedded into the PP coating during the BIM process by controlled collapse of the V-grooves. Thus, the feasibility of combining standard carrier film materials for printed flexible electronics and packaging into a non-flat polymer part was demonstrated, which could be a helpful step towards the fabrication of polymer parts with surface functionality. Keywords: printed flexible electronics; back injection molding; roll-to-roll extrusion coating; conductive nanoparticle ink; thermal bonding

In the numerous plastic applications where mechanical strength and stiffness are essential, ASA and ABS are often the materials of choice.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly