Custom Plastic Injection Molding | Order Parts Online - plastic injection mouldi

Author:gly Date: 2024-10-15

The junction housing is an interesting case because it is typically considered a âlarger partâ on 3D printing platforms. This gives it a higher per-unit price from the get-go, and also very little discount over quantity for these processes. SLS nylon still is the cheapest at quantity one, being just above $200. Around 30 units, there is actually better pricing if the part is CNC machined. Even urethane casting and HP MJF tend to be more competitive than SLS between quantities 30 and 250. Like the other parts in this study, injection molding is ultimately the clear choice for production manufacturing. The upfront tooling to mold this piece is over $10,000, but the per-unit price is so low that at 250 units it becomes dramatically more economical, by an order of magnitude, to move to injection molding tooling.Â

Overmolding: Involves molding one material over another substrate (typically a rigid plastic or metal component) to create a single integrated part with multiple layers.

More details about this process, including both tools required and costs involved, can be found in our Complete 3D Printing Guide.

Two-Shot Injection Molding: Utilizes two different materials, often with different properties, colors, or textures. Common combinations include thermoplastics with different hardness or colors.

Plastic injection molding can also be used to create custom parts in this industry. Some engineering-grade plastic resins exhibit high durability and stability, qualities complemented by excellent cost-effectiveness compared to metal and wood alternatives. Such properties are especially desirable in the case of hand tools, accessories, and fasteners.

At Thogus, we specialize in mid- to high-volume injection molding services for a wide range of industries and applications. We have decades of experience and extensive capabilities that include traditional injection molding, overmolding, and two-shot molding, as well as gas-assisted injection molding. As a result, we can customize our manufacturing services to meet the specific needs of your project with a focus on white glove customer service.

Components created via this process more often than not belong to the category of 'prototypes,' or at the very least, small-scale manufacturing. Because 3D printing has primarily become an automated process, the expertise required to operate the machinery is not that high, enabling businesses and people to engage in manufacturing experimentation.

Overmolding: Typically involves using two different materials as well, with one acting as the substrate and the other as the overmold material. The substrate is usually rigid, while the overmold material is flexible.

3D printing is a method belonging to the additive manufacturing family of processes, encompassing multiple technologies that can be used to create parts out of base materials. 3D printing has seen increased use since the technology has become less expensive and it has advanced enough to facilitate the manufacturing of complex geometries.

3D printing and injection molding are not competing, but rather complementary ways of manufacturing. Businesses (especially smaller companies that commonly use 3D printing in production) will commonly use SLS or other 3D printing techniques for rapid prototyping and low-volume production. From there theyâll switch to injection molding once the volume of parts needed is above a certain threshold. This way reduces the time and costs to mold or machine each iteration of the part design, allowing companies to develop the same products more quickly and cheaply.Â

The potentiometer knob has a bounding box of 16.81mm x 15.20mm x 15.20mm (0.662in x 0.598in x 0.598in). It is about the same size as a thimble.

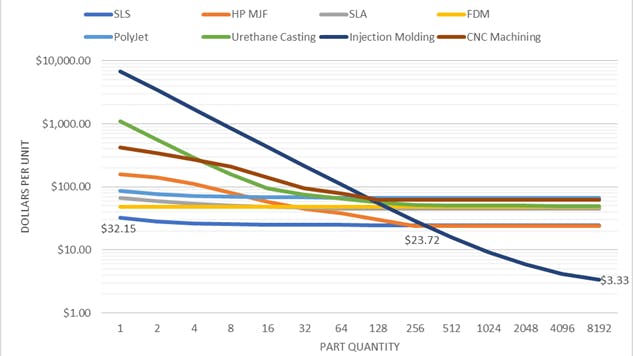

Data results for the per-unit price of the potentiometer knob are below, showing doubling quantities from 1 to 8,192 pieces.

Overmolding: Utilizes standard injection molds for the substrate component, with additional features to accommodate the overmolding process. Mold design is typically simpler for overmolding vs two-shot injection molding, as it involves molding one material over another without the need for multiple injection cycles.

The potentiometer knob tells a different story than the drone leg. Because of its small size (about the size of a thimble), it remains cost competitive using 3D printing for quantities up to 2000 units before the break-even hit to injection molding. Note that around a quantity of 30, it is more economical to move from SLS 3D printing to HP MJF 3D printing. At $3.45 per unit, HP MJF is an excellent solution to keep small batch inventory on hand using just-in-time (JIT) methodology. However, if over 2000 are needed, then injection molding can save you thousands of dollars throughout the product's lifetime. In fact, the per-unit price without tooling amortized was less than $0.80. Savings could be even higher if a multi-cavity mold tool is chosen.

There is no doubt that 3D printing is a cutting-edge manufacturing technique. The reality, however, is that most plastic parts you see both in daily life, and in industrial environments, are still made via plastic injection molding. However, the two manufacturing methods are regularly used, with 3D printing beginning to see particular interest from the space industry.

Two-Shot Injection Molding: Commonly used for creating complex parts with multiple colors, textures, or material properties in industries such as automotive (multi-color buttons, soft-touch grips), consumer electronics (multi-material casings), and medical devices (multi-material components with different tactile properties).

Data results for the per-unit price of the drone leg are shown below, showing doubling quantities from 1 to 8,192 pieces.

In general, the breakeven point between which of the two methods is most cost effective is reached between 250 and 2,000 parts (we explore this more in our case studies in the next section). While analyzing which one of the two processes would best fit your project or business, it is useful to also take into consideration the following:

Two-Shot Injection Molding: Pros include the production of complex parts with reduced assembly steps, and improved part quality. Two-shot molding also offers design flexibility and aesthetic options. The cons include a higher initial investment in tooling and equipment, limited material options, and potential challenges with material compatibility and adhesion.

We uploaded the 3D CAD files to Xometry's Instant Quoting Engineâ , which provides instant quotes for 3D printing, CNC milling, and urethane casting in various quantities. Xometry's injection molding service typically provides quotes same-day.Â

In general, two-shot injection molding is best for creating complex parts with contrasting colors, textures, and material properties. Some common parts made with two-shot molding include:

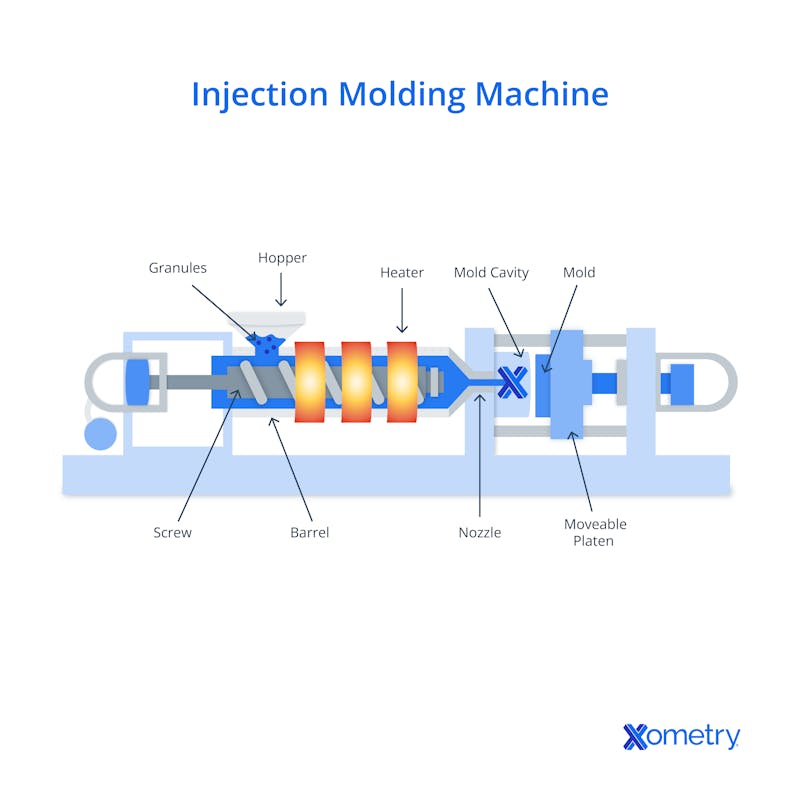

Is injection molding additive manufacturing? Definitely not. Additive manufacturing processes refer to constructing a part on a layer-by-layer basis. More information about the injection molding process can be found in our ultimate guide to injection molding.

Data results for the per-unit price of the junction housing are shown below, with doubling quantities from 1 to 8,192 pieces.

In this price study, we compare three different geometries across different processes, at different quantities and recorded the price. The geometries were a drone leg (representing a typical part), a potentiometer knob (representing a small part), and a junction housing (representing a larger part). It is important to showcase different geometries because the pricing behavior per process often relies on the size and shape of the manufactured model. The amortized price per unit is recorded at doubling quantities, from 1 to 8,192 pieces, to represent the full-in price in each of the 8 technologies reviewed.

Parts with high tensile strength that can resist extreme temperatures, comparable to their metal alternatives, can be created via plastic injection molding. This process also allows for high-volume orders that use affordable production materials (pill bottles, for example). Injection molding can also be helpful in the production of high-grade systems like the ones related to X-ray machinery.

Two-Shot Injection Molding: Requires materials that are compatible with each other and capable of adhering together during the molding process. Some materials may require pre-treatment or special bonding agents to ensure proper adhesion.

This technology has seen heavy uses in the medical and dental industry, via products and processes like bio-printing, prosthetics, and custom medical devices. 3D printing can also provide patient-specific products like implants and other dental appliances, so its use is centered around the concept of personalized healthcare.

The automotive industry uses injection molding for both large and small intricately designed parts. This includes bumpers, dashboards, cup holders, and mirror housings. The Production Part Approval Process (PPAP) production standard governs injection molded parts in this field, so companies that meet those standards are able to become Tier 1 suppliers.

As is the case with almost all manufacturing processes, large volume orders translate to lower costs. If we are to consider a relatively simple small part, some studies (including the one linked above), show that 3D printing costs would be in the order of 10%-20% less expensive than injection molding for production in the order of 20,000 parts or less. The 3D printing vs injection molding cost breakeven occurs at the 40,000-50,000 part mark, in this scenario. The actual numbers will most likely differ, depending mainly on the geometry of the part and the subsequent material use.

Injection molding vs 3D printing represents a classic debate of 'old' vs. 'new' in today's manufacturing industry. While 3D printing is the newer technology, it cannot replace the traditional manufacturing of parts provided by injection molding or other similar techniques. However, both processes are used together to move from design to full scale production. Companies will use 3D printing as they move through prototyping and design changes, and once theyâre sure of a design, theyâll move into injection molding.

The drone leg's geometry prices out the least expensive in selective laser sintered (SLS) nylon from quantities of one ($32) to roughly 250 ($24). Around this range, another 3D printing process called HP Multi Jet Fusion (HP MJF) became slightly less expensive per part. Still, at the same time, the price per unit in injection molding hit its break-even point and quickly shows its scaling benefit. The results are clear; at around a quantity of 250, it makes sense to start considering injection molding for a project with this geometry, with scaling that quickly goes to dollars a unit. This becomes roughly $3 per piece at quantities over 8000, including the cost of tooling. Given the curve, it is clear that the pricing would amortize even further as quantities increase.

3D printing has seen more and more uses in the robotics industry, as the parts used are usually small (and complex) enough to require only a one-time investment in a 3D printing machine. Customizable parts are a norm in this sector, as well as an emphasis on lightweight and durability. All of those qualities can be achieved through 3D printing.

Since this is an industry where complex parts are produced in low volumes, 3D printing is a natural fit for the aerospace sector. It has helped engineers experiment with increasing aerodynamic and engine performances while attempting to reduce weight as much as possible. The materials used in this industry range from engineering-grade thermoplastics (ULTEM 1010, reinforced Nylon, PAEK, etc.) to metal powders (such as titanium, aluminum, and stainless steel).

The ability to produce a just-in-time quantity of parts in a short amount of time is also where 3D printing shines. Compare that with injection molding, which is typically used in mass manufacturing â i.e., producing hundreds, if not thousands, of parts inexpensively.

Founded in 1950, Thogus is an established, family-owned custom plastic injection molder and contract manufacturer headquartered in Avon Lake, Ohio.

Volume does not contribute heavily to the cost of a part, but surface area does. This is especially the case with 3D printing, as large surface areas contribute to long production time and material use. Injection molding cost, however, is not that heavily affected, since the mold has to be pre-designed anyway. This pre-design may also come in a form of a 3D printed injection mold for short run applications, though these molds donât hold up for larger volumes.

The junction housing has a bounding box of 215.84mm x 172.44mm x 68.18mm (8.498in x 6.789in x 2.684in). This would be considered larger on many 3D printing platforms.

As Dr. Mark Cotteleer of Deloitte Services summed up at the 2014 SIMT Additive Manufacturing Symposium, "Additive manufacturing is not a panacea. There is no reason to view it as a universal replacement for traditional manufacturing methods. [However,] we do see it as important within the constellation of manufacturing methods that businesses can deploy in pursuit of performance, innovation, and growth."

Overmolding: Often used for adding functional or aesthetic features to existing parts, improving grip, providing cushioning, or sealing against moisture or contaminants. Common applications include tool handles, toothbrushes, electronic device casings, and medical device grips.

When manufacturing small parts, the only significant recurring cost related to 3D printing is the material used. For large ones, different, more expensive machinery is required, which significantly raises the costs of the entire manufacturing process.

This sector uses injection molded products for food processing, storage, and consumption. Products made for this industry include straws, containers, caps, filtering components, and processing equipment components. Food and beverage companies should have FDA certification while ensuring RoHS, REACH, and NSF guidelines are also followed. They can also meet GMA safe standards, set by the Grocery Manufacturers/Food Products Association to ensure food quality.Â

Injection molding and 3D printing manipulate plastics in different ways. Molding injects liquid into a form to cool into a solid part, while printing deposits multiple layers of melted plastic to build a piece from bottom to top. While 3D printing has allowed for innovative design implementation within hours (for small parts), plastic injection molding remains an industry standard for high-quality, reliable, large batch production.

Due to its versatility, the injection molding process is employed in every industry including the automotive, medical, and aerospace sectors, all of which feature different certifications. All industries, however, recognize ISO 9001 certifications for quality, and FAI (first article inspection) procedures are common in the aerospace, medical, and automotive industries. Most of these same certifications and regulations also apply to 3D printed products.

Overmolding: Similar to two-shot molding, overmolding requires compatible materials for proper adhesion. The substrate material must also be capable of withstanding the temperatures and pressures of the overmolding process without deforming or degrading.

This type of technology, while relatively new, has made its way into every industry, but it has become especially popular in those with stringent precision requirements, such as robotics and aerospace. While many of the regulations and certifications listed for injection molding above also apply to 3D printing, it is still new enough that not many have been created specifically for this manufacturing method.

Overmolding: The pros of overmolding include enhanced product functionality and aesthetics, improved ergonomics and grip, and added value to the product. Overmolding also allows for the combination of different materials with complementary properties. As for the cons, overmolding is often limited to applications where a rigid substrate is suitable for overmolding. It may require secondary operations for part preparation or substrate treatment.

3D printing usually uses CAD data to construct the desired part on a layer-by-layer basis, fusing those layers to 'grow' the part. Some common materials used in 3D printing include polymers, composites, glass, metals, and photopolymers.

Although the cost per unit is an important figure, there are several hidden costs that managers should also take into consideration when making manufacturing decisions:

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry's network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.

This article will go through the processes, applications, concrete examples, and real-world use cases of both manufacturing methods.

Aerospace companies use injection molding for products from chassis components to turbine blades to housings. Injection molding suppliers can earn AS9100 certification, and can additionally be AS9110 and AS9120 certified if they handle MRO parts or sourcing, respectively. PPAP production standards also apply in this industry, and companies producing defense products should also be ITAR compliant.

If you’re looking to enhance your product with overmolding or two-shot injection molding, we’re here to support you through every step of the process, from design optimization and material selection to secondary processes and quality assurance.

Want to check out how your parts' costs compare? Talk with Xometryâs experts today. All it takes is a 3D CAD model. Xometry accepts STEP (.step, .stp), SOLIDWORKS (.sldprt), Mesh (.stl), Parasolid (.x_t, .x_b), Autodesk Inventor (.ipt), Dassault Systems (.3dxml, .catpart), PTC, Siemens (.prt), and ACIS (.sat) file types.

Experience the Thogus Difference Connect with us today to discuss your project and to learn more about our capabilities.

All of these play a factor in manufacturing selection and vary on a case-by-case basis. Ultimately, engineers and project managers should think critically about their project goals and determine whether a combination of processes, such as 3D and injection molding, is best for them.

In contrast, overmolding is the method to go with if your primary goal is enhancing functionality or visual appeal, or to improve specific features of a part. Examples include:

Two-Shot Injection Molding: Requires specialized molds with multiple cavities or rotating cores to facilitate the injection of two materials in separate shots. Mold design complexity is higher, and the process may require additional mechanisms for material transition and registration.

Injection molding is a manufacturing process that relies on the use of molten plastic inserted into a mold cavity, producing a part with a specific shape or geometry. Injection molding is one of the most cost-effective ways of creating plastic parts, which is why these parts are everywhere in our daily lives.

When it comes to plastic injection molded components, there are nearly as many needs as there are applications. As a result, one size does not fit all when it comes to the manufacturing processes chosen to produce plastic parts. While injection molding is one of the most efficient and versatile manufacturing processes available, there are different methods within injection molding that offer an even higher level of customization and adaptability. Two of the most widely used methods are overmolding and two-shot injection molding. Both differ in their applications and approaches. Let’s take a look at the contrasts between overmolding vs two-shot injection molding, and when one might be preferred over the other.

Since this is one of the industries where consumer safety is of utmost priority, pharmaceutical and medical injection molding providers must ensure the plastic resins they use meet the industry's standards. Manufacturers can have certifications including ISO 13485 and should be able to mold in clean rooms with sterilization processes such as gamma and e beam techniques.Â

When it comes to comparing the advantages of overmolding vs two-shot injection molding, it’s important to mention which method is best suited for certain parts.

Two-Shot Injection Molding: Also known as dual-shot, multi-shot, or 2K molding, it involves injecting two different materials into a single mold in two separate cycles to create a single integrated part.

Our example drone leg has a bounding box of 146.69mm x 139.57mm x 33.00mm (5.775in x 5.495in x 1.299in). A bounding box is an imaginary box around an object that shows its dimensions in image processing.

The question of plastic injection molding vs 3D printing comes down to your project's requirements. There are pros and cons for each process that can help guide you to a decision.

One of the most significant advantages 3D printing has given aerospace manufacturers is the ability to test functional part prototypes. Advancements in 3D printing have been spearheaded by industry leaders such as Airbus, Boeing, and Safran.

Injection molding cost is heavily influenced by product iteration. That means that with a change of design, a change of mold is also required. This puts 3D printing at a notable advantage in this comparison. No tooling costs are attached to a change of design in the case of this type of additive manufacturing technique. Plastic injection molding vs 3D printing cost breakeven is thus also affected by the possibility or expectation of such a change in part design.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly