Custom Molded Plastic Parts - custom molders

Author:gly Date: 2024-10-15

You can easily operate iQ flow control as well as the hardware devices with the CC300 machine control. Important mold temperature control parameters in the injection molding process are available. The actual values of all temperature control circuits as well as those of the temperature control units, are displayed on the injection molding machine control. Changes and errors can’t be missed.

All-Plastics has expertise in providing cost-saving, high quality injection molding solutions to the Medical Device industry. Our expertise in medical injection molding allow us to support tight tolerance micro-sized components to complete medical devices.

By bundling several temperature control circuits, less temperature control units are needed. This reduces the investment costs. Customer trials have shown that with ideal design and the recommended operating mode, the return on investment (ROI) can be two years.

All-Plastics caters to your need for durable plastic medical components that comply with strict FDA standards and regulations.

By employing advanced medical injection molding in our manufacturing process, we are able to supply high volumes of medical components without sacrificing quality while meeting your target specifications.

Borgmann GmbH relies on digital solutions from ENGEL to maximize process stability and repeatability in production. The result: an impressive increase in efficiency and product quality while reducing costs.

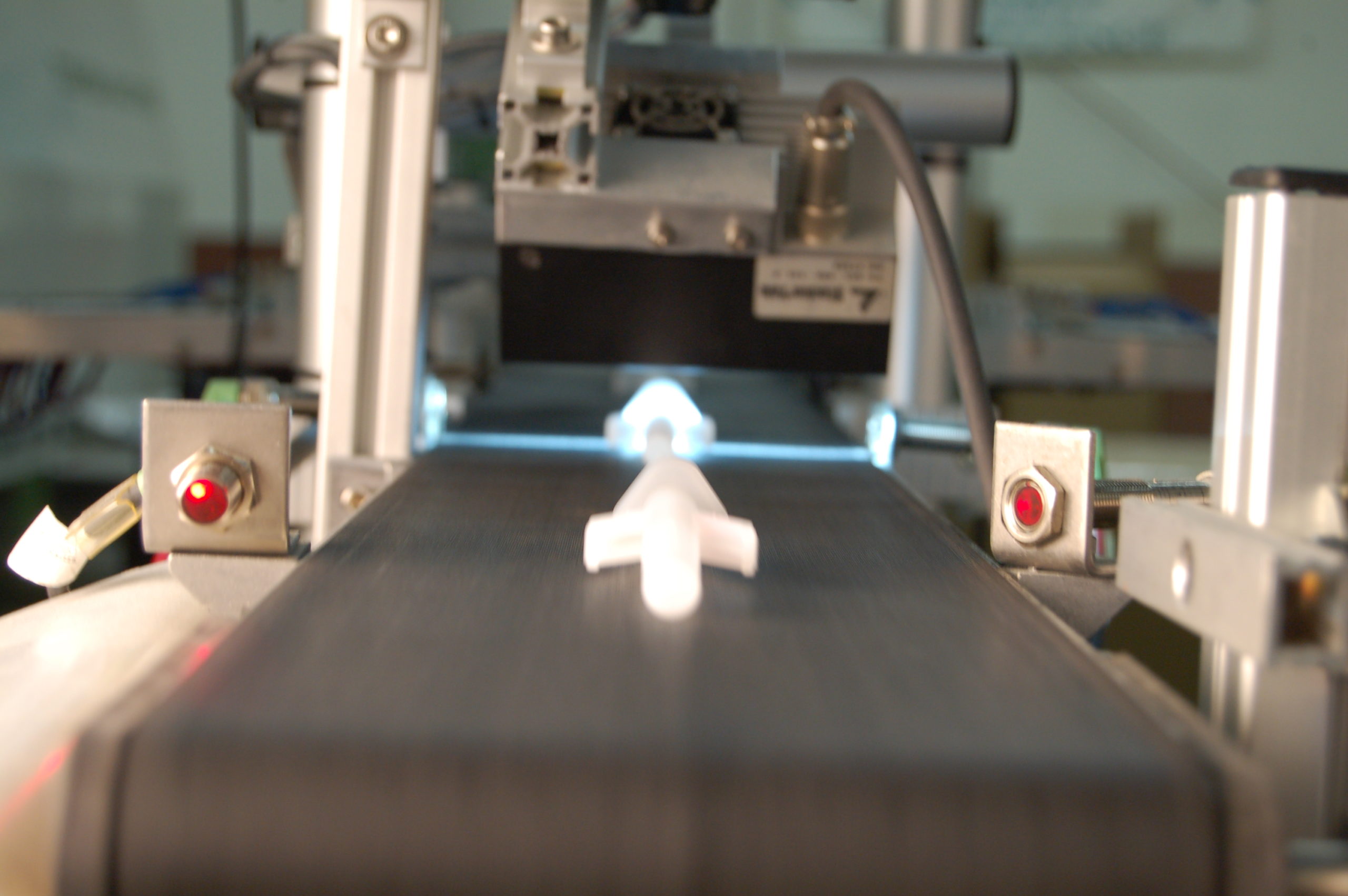

Medical injection molding is a plastic molding and manufacturing process involving liquefied plastic into a mold to create plastic products of various shapes and sizes. In this process, the plastic is allowed to conform to the shape of the mold and harden to produce the desired finished product.

Injection molding is one of the most widely used manufacturing processes, capable of producing intricate plastic parts with high precision. However, like any industrial process, it has its challenges, and…

All-Plastics employs a state-of-the-art plastic injection molding process in order to produce high-quality medical products that meet the strict guidelines set by regulatory bodies. This ensures the safety and efficiency of all manufactured medical products and tools, which include:

Optimum temperature distribution in the cavity is crucial to produce, for example, high-gloss surfaces. As no shading occurs on the plastic parts and the gloss level remains uniform.

Our experts provide Project Management solutions from Concept to Operational Excellence, including full program documentation and component traceability. REQUEST A QUOTE

iQ flow control monitors the temperature difference in each distribution circuit of the e-flomo plus. The software calculates the cooling water requirement and passes this information on to the temperature control unit. The temperature control unit provides the appropriate amount of water and automatically adjusts to changing parameters.

The iQ flow control software continuously adjusts the speed of the pumps in the temperature control units during production. Customer calculations show that this can reduce the energy consumption of the temperature control process by 85%. This results in CO2 savings of approx. 160 t per year.

Intelligent mold temperature control in injection molding means that the pump does not have to operate constantly at full load. This reduces wear and the pump can be used for longer. Maintenance costs for temperature control units are cut down by up to 50%.

Find out more about the interaction of ENGEL temperature control solutions during operation and how Borgmann benefits from this.

Material selection and method of production are always key considerations in the manufacturing of products, devices, and components for the medical industry. This is because of the strict regulations and standards that govern the industry. Plastic injection molding meets these requirements and offers a wide range of benefits for the medical industry.

All-Plastics works with a variety of medical industries to provide injection molding services to help create, design, and mold custom applications and parts. Some of the medical markets we serve are:

Intelligent mold temperature control in injection molding means that the pump does not have to operate constantly at full load. This reduces wear and the pump can be used for longer. Maintenance costs for temperature control units are cut down by up to 50%.

The decisive factor for mold temperature control in injection molding is the interaction of the three temperature control components e-temp, e-flomo plus and iQ flow control.

The iQ flow control software continuously adjusts the speed of the pumps in the temperature control units during production. Customer calculations show that this can reduce the energy consumption of the temperature control process by 85%. This results in CO2 savings of approx. 160 t per year.

The temperature control unit and the water flow regulator provide the data that can be monitored, optimized, documented, and actively controlled using iQ flow control. This enables you to make your mold temperature control in injection molding repeatable, time-saving and convenient. Both devices are fully integrated in the CC300 machine controller.

If your smartphone has a clear, durable casing, it's likely made of polycarbonate. This thermoplastic polymer is a popular material among plastic parts, components, and products manufacturers. Its qualities, such…

The pump in the e-temp temperature control unit enables energy-efficient operation of your injection molding machine by automatically adjusting the pump speed.

The compact e-flomo plus devices replace traditional cooling water flow regulators with floatation metering, which determine and control the actual flow rates required.

Optimum temperature distribution in the cavity is crucial to produce, for example, high-gloss surfaces. As no shading occurs on the plastic parts and the gloss level remains uniform.

By bundling several temperature control circuits, less temperature control units are needed. This reduces the investment costs. Customer trials have shown that with ideal design and the recommended operating mode, the return on investment (ROI) can be two years.

iQ flow control monitors the temperature difference in each distribution circuit of the e-flomo plus. The software calculates the cooling water requirement and passes this information on to the temperature control unit. The temperature control unit provides the appropriate amount of water and automatically adjusts to changing parameters.

Based on the measurement results of the e-flomo plus water distribution system, iQ flow control automatically optimizes mold temperature control in injection molding production in combination with the ENGEL e-temp temperature control unit. The temperature control unit and iQ flow control self-regulate pump output and water quantities to a minimum. This creates consistent conditions throughout the injection molding process and higher energy efficiency.

20% of rejects in the injection molding industry are caused by temperature control errors. iQ flow control decreases this number by increasing process consistency. If fluctuations occur, the machine is stopped before rejects are being produced.

The ENGEL temperature control system advanced to complete success at Blum thanks to savings in energy, raw materials and time.

20% of rejects in the injection molding industry are caused by temperature control errors. iQ flow control decreases this number by increasing process consistency. If fluctuations occur, the machine is stopped before rejects are being produced.

Our experts are happy to answer any questions you may have about mold temperature control in injection molding and support you in optimizing your part quality as well as reducing your energy costs.

The ideal differential temperature control is repeatable during the next production. Mold temperature control in injection molding allows the production of good parts without repeating trials.

Our medical plastic injection molding and clean room molding production solutions that increase quality, security and provide cost advantages for the Medical Market are:

The ideal differential temperature control is repeatable during the next production. Mold temperature control in injection molding allows the production of good parts without repeating trials.

20% of rejects in injection molding are a result of mold temperature control errors. Process monitoring and a stable temperature control process are essential prerequisites for consistent production processes and high product quality. The digital product, iQ flow control, automatically adjusts the mold temperature control.

You can easily operate iQ flow control as well as the hardware devices with the CC300 machine control. Important mold temperature control parameters in the injection molding process are available. The actual values of all temperature control circuits as well as those of the temperature control units, are displayed on the injection molding machine control. Changes and errors can’t be missed.

Mold temperature control in injection molding has a considerable influence on product quality. Procter & Gamble Manufacturing is therefore increasing the transparency and consistency of the temperature control processes with e-flomo and iQ flow control by ENGEL.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly