Create · Precious Plastic Toolbox - precious plastic moulds

Author:gly Date: 2024-10-15

The main difference between compression molding and injection molding involves the way that plastic or rubber enters the mold. Compression molding places a pre-measured amount of material into a mold, which is then closed and heated under pressure. With injection molding, the material is heated and injected into a closed mold cavity under high pressure instead.

Compression molding and injection molding can process some of the same elastomers, including silicone and fluorosilicone. It’s important to note, however, that compression molding uses gum-like high-consistency rubber (HCR) while injection molding uses liquid silicone rubber (LSR) instead.

Compression molding vs. injection molding is a contest between two of the most popular ways to mold plastic and rubber parts. Each process has advantages and applications, but what’s the best choice for your next project? To answer that question, you’ll need to understand how each process works and where they differ.

When comparing compression molding vs. injection molding, determine whether the molding process you want to use can support the molding material you plan to select. There are many types of molding materials, but they can be divided into plastic, rubber, and composites.

This method involves the use of mechanical tools, such as abrasive stones, sandpaper, polishing compounds, and buffing wheels, to manually polish the mold surfaces. It requires skilled operators who carefully remove imperfections and achieve the desired smoothness and finish.

Injection molding flow marks are a common injection molding defect. While flow marks generally do not influence the structural integrity

By signing up, you agree to our Terms of Use and Privacy Policy. We may use the info you submit to contact you and use data from third parties to personalize your experience.

Evaluate the complexity of the mold design, including intricate details, thin walls, and complex geometries. Some polishing methods may be better suited for reaching difficult-to-access areas or polishing intricate features.

There are some differences between molding processes, however. With compression molding, the core is the stationary top half of the mold and the cavity is the moveable bottom half. With injection molding, the core is usually (but not always) movable. In most injection molds, the core moves away from the cavity, which is stationary, and holds the part until it’s ejected.

The molds, or tools, used with compression molding and injection molding have some things in common but also some important differences.

Electrolytic polishing uses an electrochemical process to remove surface imperfections. The mold is immersed in an electrolyte solution, and an electric current is applied to selectively dissolve the high spots and rough areas. This method is suitable for complex mold shapes and provides precise control over the polishing process.

Create high quality custom mechanicals with precision and accuracy.

Three-plate molds have a third plate called the stripper plate that’s placed between the core and the cavity. Including this third plate adds costs and means the mold has two parting lines. Because the stripper plate separates the runner system from the molded part, it helps speed production. Three-plate injection molds are used only with cold runner systems.

Compression molding can produce larger and heavier parts than injection molding. Still, that doesn’t mean designers can’t use injection molding for parts like automotive dashboards. Plus, both molding processes can produce smaller parts as well. Examples include the facepieces for respirators and CPAP machines.

The polishing process typically involves using a series of abrasive materials, such as sandpaper, polishing compounds, and buffing wheels, along with various techniques and equipment. Skilled technicians carefully work on the mold surfaces, gradually removing imperfections and achieving the desired level of smoothness and shine.

Injection molds may also need sliders, lifters, or hand loads to release parts with undercuts. Compression molds can use sliders, too, but most compression-molded parts are simple enough not to require them. Adding ejection mechanisms to a tool increases costs, which undercuts one of compression molding’s main advantages over injection molding.

A compression molding press is a simpler piece of equipment than an injection molding machine. Loading a compression mold is a manual process, and an operator must physically close the tool. By contrast, modern injection molding machines are highly automated. Even the hopper where resin is loaded may be programmable.

Fluid polishing, also known as abrasive flow machining, involves the use of a viscous abrasive media that is forced through the mold cavities and cores under pressure. The abrasive particles in the fluid flow help remove imperfections and polish the mold surfaces. This method is suitable for achieving consistent and uniform polishing on complex mold geometries.

Two-plate molds are the most common and cost-effective type of injection mold. They have a single parting line where the core and cavity plates meet. These injection molds are especially efficient when they have multiple cavities, and they work well with any type of runner system.

Compression molding can’t match injection molding’s part tolerances, but compression-molded components still have good dimensional accuracy. Compression-molded parts can also include features, such as threads, that support product assembly. With both molding processes, designers who use tolerance stack-ups can demonstrate how parts fit together.

There are three main types of compression molds: flash, positive, and semi-positive. The differences between them involve the amount of material that’s used and the amount of flash that’s produced. In general, compression molding produces more flash than injection molding.

By signing up, you agree to our Terms of Use and Privacy Policy. We may use the info you submit to contact you and use data from third parties to personalize your experience.

Compression molding and injection molding both support overmolding and insert molding, processes that eliminate post-molding part assembly.

Positive molds cost more than flash molds but require careful measurement of the material. Typically, they’re used with deep draw parts and when it’s important to control part density. Because positive molds produce less flash, they’re a good choice for more expensive materials.

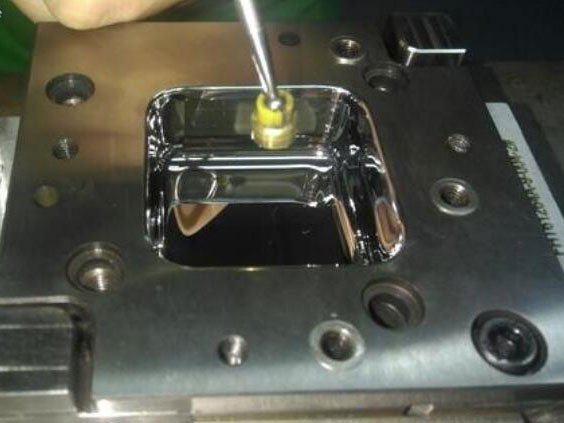

Mold polishing significantly enhances the visual appeal of the injection-molded parts. The mirror-like finish achieved through polishing gives the parts a professional and premium look. This is particularly crucial for applications where aesthetics are important, such as consumer products, automotive components, and medical devices. A well-polished mold ensures that the final parts have a smooth, glossy surface without blemishes or surface imperfections.

Flash molds are the simplest, least expensive, and most popular compression molds. Because flash escapes between the parting line, however, these tools are often used with less expensive materials.

Mold polishing significantly enhances the surface finish of the mold cavity and core, which translates to superior part quality. The smooth and polished mold surfaces help achieve precise and consistent part dimensions, minimizing variations and ensuring the accurate reproduction of intricate details. This results in high-quality molded parts with excellent aesthetics and improved functionality.

Access a wide breadth of capabilities through our highly vetted network.

Explore the world of mold surface texture in injection molding, where the visual and tactile qualities of a part are meticulously crafted. This post explores the standard of surface texture. Discover how to choose a suitable injection molding surface finish and the common methods for applying textures to injection molding tools. delve into the art

Steel and aluminum are the most commonly used materials of construction for compression molds and injection molds. Both metals come in various types or grades. For example, compression molds can be made of soft, semi-hardened, or hardened steels. Grades of aluminum can be used instead, but aluminum can’t match steel for tighter part tolerances or tooling life.

For compression-molded parts where cycle times are a concern, multi-cavity molds can help speed parts production. Post-processing is also a factor. Because injection molding is performed at higher clamping pressures, there’s usually less flash. For both molding processes, however, either manual trimming or cryogenic deflashing can be used.

Stack injection molds consist of multiple parallel mold plates that are “stacked” together to create multiple faces or levels for injection molding. They have higher up-front costs but require less clamping tonnage per cycle. These injection molds can accommodate various materials simultaneously for greater flexibility in production.

Chemical polishing involves the use of chemical agents or solutions to dissolve a thin layer of the mold surface, resulting in a smoother finish. The chemicals used can vary depending on the type of mold material. This method is effective for achieving a high level of surface smoothness and can be combined with mechanical polishing for optimal results.

By signing up, you agree to our Terms of Use and Privacy Policy. We may use the info you submit to contact you and use data from third parties to personalize your experience.

In conclusion, mold polishing plays a vital role in the injection molding process. Enhancing the appearance, functionality, and dimensional accuracy of molded parts, ensures high-quality results and customer satisfaction. The various types of mold polishing methods offer different advantages and characteristics, making it crucial to choose the most suitable approach for each specific application. Considering factors such as part complexity, surface finish requirements, production volume, and cost will help in selecting the appropriate mold polishing method. By prioritizing mold polishing and incorporating it into the injection molding workflow, manufacturers can achieve exceptional part quality and maximize the potential of their molds.

Accelerate development with instant quotes, expert DFM, and automated production updates.

Because injection molding supports more detailed designs, its design rules are both more numerous and complex. With both molding processes, however, it’s essential to avoid excessively thick walls, unnecessary undercuts, sharp corners, and sudden changes in wall thickness. This helps to minimize the risk of defects while also controlling costs.

By signing up, you agree to our Terms of Use and Privacy Policy. We may use the info you submit to contact you and use data from third parties to personalize your experience.

As we mentioned above, each mold polishing method has its advantages and suitability for specific mold materials, shapes, and desired finishes. It is important to choose the appropriate method. What factors should be considered when we make the selection? Here are some suggestions.

We exist to eliminate bottlenecks in new product development by integrating the people, processes, and platform you need to source custom parts.

During plastic injection molding, injection pressures can reach 30,000 to 40,000 pounds per square inch (psi). The clamping pressure is even higher so the mold won’t open while plastic is injected. Compression molding is performed at lower clamping pressures and some compression molds aren’t pre-heated. By contrast, injection molds require preheating to improve part quality. Cooling systems may also be part of the injection mold.

Compression molding and injection molding are plastics manufacturing processes that each have advantages. No matter what you decide, you’ll make the right choice when you partner with Fictiv. Along with your request for a quote, you’ll receive design for manufacturability (DFM) feedback that can help you avoid defects and reduce troubleshooting. Fictiv works with a carefully vetted network of global partners, so why look for a molder on your own?

Magnetic polishing utilizes a mixture of abrasive particles and a magnetic field to polish the mold surfaces. The mold is placed in a container with the abrasive media, and the magnetic field induces movement and agitation of the particles against the mold surface, resulting in polishing and smoothing.

Injection molding has significantly shorter cycle times than compression molding. That makes it a better choice for higher part volumes, but low-volume injection molding can be used for projects ranging from 100 to 10,000 pieces. Below 100 parts, designers may want to use compression molding instead – but 3D printing or even urethane casting are also options.

By signing up, you agree to our Terms of Use and Privacy Policy. We may use the info you submit to contact you and use data from third parties to personalize your experience.

Consider the project timeline and available resources. Some polishing methods may require more time and labor-intensive processes, while others offer quicker results. Balance the need for speed with the desired level of quality.

Mold polishing contributes to achieving consistent part dimensions and improved dimensional accuracy. The removal of imperfections and the creation of smooth mold surfaces help maintain uniform resin flow and cooling during the injection molding process. This minimizes variations in part dimensions and ensures that each molded part meets the required specifications and tolerances.

Evaluate the cost-effectiveness of different polishing methods. Some techniques, such as ultrasonic or electrolytic polishing, may involve higher equipment and material costs. Assess the budget and weigh the benefits of each method against the associated expenses.

By signing up, you agree to our Terms of Use and Privacy Policy. We may use the info you submit to contact you and use data from third parties to personalize your experience.

Mold polishing or texturing adds complexity, however, which can undercut some of the main advantages of compression molding: simpler mold designs and lower tooling costs.

By signing up, you agree to our Terms of Use and Privacy Policy. We may use the info you submit to contact you and use data from third parties to personalize your experience.

Compression molding also supports the use of thermosets, polymers that can be liquefied once but have better mechanical properties than thermoplastics. Although some injection molding machines support thermosets, most do not. That’s because thermoset injection molding requires special screws and barrels for the injector unit.

Keep reading to learn more. Then, when it’s time to start your project, create a free Fictiv account and upload your part drawing. Whether you need compression molding or injection molding, we have what you need.

By signing up, you agree to our Terms of Use and Privacy Policy. We may use the info you submit to contact you and use data from third parties to personalize your experience.

Compression molding and injection molding can process many of the same thermoplastic resins. In addition, both processes support the use of commodity plastics and specialty plastics and polymer blends. Examples of these thermoplastics include:

Bulk molding compound (BMC) is a thermoset composite that’s used only with compression molding. It has a dough-like consistency and is a combination of polymer resins, chopper fibers, and a hardening agent. Sheet molding compound (SMC), a polyester reinforced with glass fibers, is also compression molded because of its consistency.

It is often beneficial to consult with experienced mold polishers or mold manufacturers to determine the most suitable polishing method for your specific requirements. They can provide insights based on their expertise and help you achieve the desired surface finish while considering practical considerations.

Determine the desired surface finish for the molded parts. If a high-gloss, mirror-like finish is required, a combination of mechanical and chemical polishing methods may be appropriate. For less critical applications, a simpler polishing method may be sufficient.

By signing up, you agree to our Terms of Use and Privacy Policy. We may use the info you submit to contact you and use data from third parties to personalize your experience.

Typically, CNC machining transforms a block of metal into mold plates. Compression molds can be die cast instead, but the dies still require CNC machining. Most injection molds are produced with CNC machining. They can be produced with electrical discharge machining (EDM) as well, or with a combination of CNC machining and EDM.

Proper mold polishing helps minimize defects in the injection-molded parts. By eliminating surface imperfections, such as tool marks, scratches, or rough textures, mold polishing reduces the occurrence of defects like flow lines, sink marks, and part sticking. The smoother mold surfaces allow for better resin flow and cooling, reducing the risk of filling inconsistencies and promoting uniform part properties.

Injection-molded parts and compression-molded parts can both have a smooth surface finish. Designers can also specify a polished, glossy, or textured part finish instead. This desired finish is applied toward the end of the mold-making process and then during molding, is transferred from the mold to the surface of the parts.

Have you ever noticed a whitening phenomenon in PVC product whitening? Some of your transparent PVC products, like shower curtains

Mold polishing plays a crucial role in the injection molding process due to its numerous benefits and contributions to part quality and performance. By investing in proper mold polishing techniques, manufacturers can achieve high-quality injection-molded parts that meet the highest standards of performance, aesthetics, and functionality.

These differences are important, but they don’t tell the full story of compression vs. injection molding. For example, compression molding has lower tooling costs but longer cycle times. That makes it a good choice for lower part volumes, but low-volume injection molding is also an option – if you have the right partner.

Compression molding is used with flat parts, thin-walled parts, and components with relatively smooth contours and simple geometries. It’s not a good choice for parts with sharp edges, steep angles, or intricate details. For complex parts, injection molding is a better choice instead. Examples include the intricate enclosure components that Lampix needed for an AR projector.

Mold polishing is essential in injection molding as it directly impacts the quality and appearance of the final plastic parts. Properly polished molds help prevent issues like flash, part sticking, and uneven filling, resulting in improved part accuracy, reduced production waste, and enhanced overall part performance.

Injection mold polishing refers to the process of refining and smoothing the surfaces of the mold cavity and core used in injection molding. It involves the removal of imperfections, such as tool marks, scratches, and rough textures, to achieve a high-quality and mirror-like finish on the mold surfaces. The goal of mold polishing is to ensure that the molds produce parts with precise dimensions, excellent surface quality, and minimal defects. Click here to learn what is mold cavity and core.

When comparing compression molding vs. injection molding, consider part size, part tolerance, part complexity, design rules, and surface finish. Otherwise, a part designed incorrectly or for the wrong process can result in molding defects like warpage and shrinkage.

Our trained employees ensure your parts will be delivered on time and to spec.

Injection mold polishing plays a crucial role in the manufacturing process of plastic components. It is a technique used to enhance the surface finish and overall quality of injection molds, ensuring precise and flawless production. By carefully refining the mold surfaces, polishing helps achieve optimal part performance and aesthetics. In this post, we will explore the world of injection mold polishing, its importance, and the different methods used. Understanding the significance of mold polishing and the techniques available will enable manufacturers to achieve superior results in their injection molding processes.

Consider the type of material used for the mold, such as steel, aluminum, or plastic. Different materials may require specific polishing methods to achieve the desired finish without causing damage.

The injection mold structure and design directly influence various aspects of the final product, including its dimensional accuracy, surface finish,

Injection molding also supports the use of family molds. These tools have multiple cavities, but they produce different parts in a single cycle. For example, an injection molder can use a family mold to produce the left and right panels for a two-part enclosure.

Compression molding and injection molding are both used in a variety of industrial applications. Examples include aerospace, automotive, and electronics. These molding techniques are also used in consumer products and medical and dental applications. Although injection molding is better for high volumes of parts, compression molding can support personalized applications such as dentures because of its lower tooling costs.

Compression molding and injection molding both use heat and pressure to produce parts. More specifically, the molding material is heated so that it flows and fills the mold cavity. Pressure is applied to the tool to hold the mold shut. After the part cools, it’s released from the mold and may require post-processing.

Semi-positive molds combine the advantages of flash and positive molds; however, they’re also the most expensive type of compression mold. Semi-positive molds do not require precise material measurements, but it’s still important to minimize flash to limit post-processing.

We exist to eliminate bottlenecks in new product development by integrating the people, processes, and platform you need to source custom parts.

Some composite materials are highly resistant to flow, and that makes compression molding the right choice since the material doesn’t have to flow through a series of channels. Examples include electrically-conductive silicones and fluorosilicones that contain metal, metal-coated, or bimetallic particles.

Ultrasonic polishing utilizes high-frequency vibrations combined with abrasive particles to remove surface imperfections. It is particularly effective for polishing intricate and hard-to-reach areas of the mold. The ultrasonic energy enhances the polishing action and allows for better control and precision.

Compression molds are less expensive because they’re simpler and require less machining. Plus, they may not require release mechanisms since compression-molded parts can be removed from the tool by hand. By contrast, injection molds require metal ejector pins.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly