China Plastic Mold/Mould Injection Maker/Manufacturer ... - plastic mould maker

Author:gly Date: 2024-10-15

Olahraga & KenyamananADP memiliki berbagai macam bahan baku untuk berbagai aplikasi termasuk alas kaki, peralatan olahraga, kacamata dan perangkat yang dapat dikenakan, tekstil fungsional, dan kulit buatan.

Proto Labs, Inc. 5540 Pioneer Creek Dr. Maple Plain, MN 55359 United States P: 877-479-3680 F: 763-479-2679 E: [email protected]

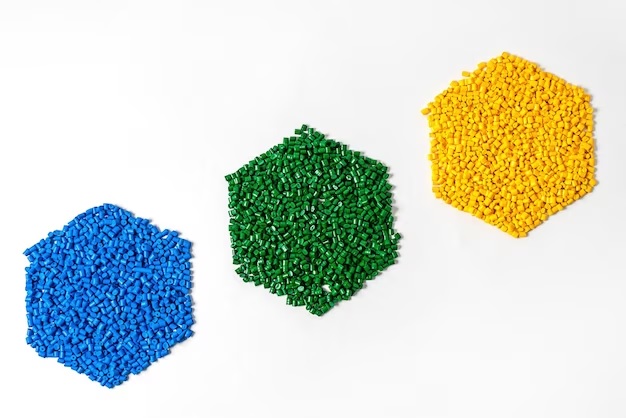

After the ingredient is ready, after that ingredient raw will be mixed with a number of ingredients added as color, cooler, or filler. For carrying out the mixing process, it is done with a machine that consists of two rotating cylinders in opposite directions.

No one ever said that designing and manufacturing molded parts was easy. Our goal is to get you through it quickly and with quality parts. A good starting point is our Design for Moldability Toolkit.

Next ingredient raw will be heated until they reach a suitable temperature for the injection process. The heating process is done using a machine that consists of a number of zone temperature heaters that could be arranged in accordance with need.

PETG ( polyethylene terephthalate glycol ) is the wrong one, the same type of plastic often used in the molding process injection. PETG has almost similar characteristics to polycarbonate. However, they are more flexible and also stand to wear and tear. Besides it, type PETG plastic _ also could stand ingredient chemicals and stand temperature high, so making it often applied _ in production requires resilience to temperature or chemistry.

POM-H (Polyoxymethylene homopolymer) POM-H has strength mechanics, rigidity, hardness, and more resistance compared to POM-C. With coefficient expansion, the heat is lower. This type of POM has advantages, that is

Tough Black (Loctite Henkel 3843) and Ceramic-Filled (BASF 3280) are two new advanced photopolymer materials now available for 3D printing.

Aluminum moldsStandard lead times as fast as 7 daysTolerances of +/-0.003 in. plus resin tolerance (in./in.)Set-up fees apply to each run Consultative Design Services (CDS)Finishing OptionsNo minimum order quantities (MOQ)Quick-turn shipping in as fast as 1 day

Because of the initial capital investment in tooling, injection molding makes sense for higher volumes of parts. Our mold cost starts at $1,495 and will vary depending on part geometry and complexity. Other factors that will impact injection molding cost are lead times and material.

We have two unique offers to meet your needs wherever you are in the product lifecycle. Our prototype injection molding process helps you cut product development cycles by weeks—sometimes months—and bridge to production with injection-molded parts within days. Our On-demand Manufacturing process is designed to meet your production needs, and helps you qualify parts quickly to seamlessly transition into production with scientific molding, in-process CMM inspections with GD&T, and a full suite of secondary operations to make sure that your parts show up and perform as expected.

After the raw ingredient reaches the required temperature, the next will open the print, and the product will be removed. That is the process called demolding.

In injection Molding for the generic grade PETG plastic process, there are a number of necessary things followed to produce a quality product.

Our helpful design aid demonstrates part features that are too thin or too thick, bad bosses, right and wrong ribs, and other considerations to be mindful of while designing parts for injection molding.

Plastic injection molding is a manufacturing process where resin in a barrel is heated to a molten state, then shot into a mold to form a final production-grade thermoplastic part.

Liquid silicone rubber molding is a thermoset process that mixes a two-component compound together, which is then heat cured in the mold with a platinum catalyst to produce a final part.

Make the move from prototyping to on-demand manufacturing for affordable, high-quality molded parts within days. Better yet, your prototyping tool is free once you shift to an on-demand manufacturing tool. Working with a single supplier that provides free design consultation services also massively speeds up the manufacturing process, allowing for greater supply chain flexibility, more consistent parts, and making qualification a breeze.

Overmolding and insert molding are two-part injection molding processes where one material is overlaid onto a second substrate part or metal insert to create a single component.

No Minimum Order Quantities (MOQs)Procuring parts on demand, without MOQs, helps you manage market or demand volatility and provides a cost-effective source for bridge production, line-down emergencies, end-of-life production, or product customization.

Design for Manufacturing FeedbackEvery quote includes real-time pricing and design analysis. We evaluate your 3D CAD and help identify any features that may pose challenges during the molding process such as difficult to machine undercuts and insufficient draft.

Peralatan Rumah tanggaADP melayani industri rumah tangga dan produksi peralatan rumah tangga seperti blender, aplikasi dapur, juga wadah pengemasan makanan.

Machine print injection plastic ( also known as machine print injection ) will have a variable size in tolerance distance close.

KosmetikADP terus meningkatkan estetika dalam pengemasan industri kosmetik dengan aplikasi polimer kosmetik dan perawatan pribadi.

After the raw ingredient is pressed for printing, the next raw ingredient will be saved in print with a temperature certain until the temperature is down to the required limit _ for the demolding process. This process is normally called cooling.

Operasikan dalam kondisi paling ekstrem sambil memenuhi spesifikasi yang ketat. ADP memahami itu dan menyediakan bahan berkualitas terbaik.

POM-C, known as Polyoxymethylene Copolymer, is a combination coefficient swipe low, level good abrasion, with material hardness. So POM-C is very suitable for applications that require high precision. This POM has characteristics main, namely :

We do quoting a little differently. When you request an injection molding quote, you'll not only receive accurate pricing, but also a manufacturing analysis—within just a few hours. Our online quoting platform also provides you with gate and ejector pin layouts and a price curve tool to help select the best tooling option for your project.

ADP hadir di industri otomotif khususnya roda 4 dan roda 2 meliputi elemen interior dan eksterior, penerangan, suku cadang mesin, tempat duduk dan kemasan baterai kendaraan listrik (EVB), menggunakan bahan baku khusus untuk plastik, pelapis, perekat, termoplastik, busa , film, komposit, dan lainnya.

If you want to print the best POM injection, then you can visit ADP, a company that provides POM with quality, high and reliable, stability, and good dimensions.

Injection molding is widely used for plastic part production in medical, consumer, and automotive industries. Typical parts include:

What is meant by mold POM injection? Polyoxymethylene or the, usually known as POM, is a thermoplastic material engineering class that has a combination coefficient swipe low with a level of good abrasion and sufficient material hardness. Thermoplastic is included in semi-crystal engineering white and is naturally used for applications that require precision, tall kind of metal, low friction, and stability in every dimension. And because strength, tensile, and resistance high mouth _ allow POM to bring together gap intermediate material properties apart from big plastic and metal. POM applications include wheel tooth size small, electronic House stairs, and so on.

We have wide selection of more than 100 thermoplastic and thermoset materials. And if you're looking for alternative material options, check out our guide to resin substitutes for ABS, PC, PP, and other commonly molded plastics.

You need to be careful with the resulting gas-burning POM-H because every content is toxic. This type of POM is usually used in industry automotive, agriculture, construction, consumer products, health, application industry, amalgamation, and packaging.

Injection molding is plastic manufacturing process that can produce high quality parts at scale. It's typically used for low- to high-volume production but our aluminum tooling can also make prototyping runs economical.

That’s the process so that PETG Injection Molding Produces Quality Products, for those of you who need it, you can trust ADP. ADP is a leading polymer provider in Indonesia with more than 30 years of experience. In addition, it is also ready to help every industry to serve leading manufacturers in various industries by offering one-stop raw material solutions to meet all your needs. For example various kinds of plastic commodities such as engineering plastics, super engineering plastics, coatings and additives. For more complete information, please visit our official website at https://adpi.co/.

After the product is released from the mold, there will be a finishing process, namely the process of cutting, scraping, and pen.

KonstruksiADP memiliki banyak produk untuk bahan baku industri konstruksi seperti isolasi, lantai, atap, dinding, fasad, pintu, jendela atau saluran pipa.

In most cases, we can maintain a machining tolerance of +/- 0.003 in. (0.08mm) with an included resin tolerance that can be greater than but no less than +/- 0.002 in./in. (0.002mm/mm).

This complete reference guide walks you through everything from quoting, design analysis, and shipment to best practices that ensure your model is optimized for molding.

We combine scientific (or decoupled) molding techniques, which optimize and lock in processing parameters to ensure part consistency—with extra attention paid to critical-to-quality dimensions using our proprietary automated CMM process. Plus, with every order you'll get:

Terakhir, ADP terus meningkatkan aplikasi industri energi & sumber daya seperti panel surya, penyimpanan energi atau bilah angin dan menara, berkat bahan baku khusus kami untuk plastik, pelapis, elastomer, resin poliuretan, TPU, dan lainnya.

Yes, we offer a production tooling option called on-demand manufacturing. This tooling option provides several benefits: lower piece part price, multi-cavity capabilities, guaranteed tooling for the life of the project (we will cut a new tool if it wears out), and first article inspections.

Our digital factories create prototypes and low-volume parts fast, while our manufacturing network, offers advanced capabilities and volume pricing.

Injection Molding ExpertiseWe'll work with you throughout the course of your project to help you quickly move from prototyping to production, including finishing options and inspection reporting.

ADP penuh dengan pilihan bahan baku yang komprehensif untuk formulasi bahan kimia & cat yang sangat menuntut yang digunakan untuk pelapis arsitektural, pelapis otomotif dan kendaraan komersial atau pelapis industri.

Not only the types of POM you must know, but you also must know the reason why great people take advantage of print POM injection.

Before starting the injection process, it is necessary to prepare ingredient PETG raw materials especially first. Generally, ingredient default shaped granules or powder, which will then be entered into in machine hoppers injection.

Unmatched Lead TimesReduce your product development cycle by weeks—sometimes months—and bridge to production with injection-molded parts within days. Some injection molding orders can ship in as fast as 1 day.

The printing process uses plastic with type Cold runners or Hot runners, depending on the product. Type Hot runners are counted as more complex and usually used at the moment part then injected into another part. Printing process injection plastic is given a ranking based on pressure or tonnage.

Get machined parts anodized and chromate plated with our quick-turn finishing option. Eligible materials include aluminum 6061/6082 and 7075.

The next raw ingredient will be transferred to an in-machine injection. On machine injection, all materials will be pressed using a plunger or pistons to emit ingredients raw through the hole injection on the mold.

For applications that require friction and are low, then POM is the right choice. In addition, regular POM is used to manufacture strong, smooth, and flexible components ( or components that are just plastic that consists of one property). So POM is very suitable for producing mechanisms and wheel tooth slides. And no wonder some great people take advantage of ingredient print POM injection to perform reduction friction.

Dalam industri kelistrikan ADP bergerak di bidang Fiber Optic Cable, meteran listrik dan air serta produsen socket dan elektronik.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly