Blend Amorphous PHA with PLA to Improve injection ... - injection moulding pla

Author:gly Date: 2024-10-15

3. Size and Weight Limitations: may not be suitable for very large or heavy parts due to equipment and handling limitations.

4. Parting Line and Flash: possible parting lines and flash, which may require additional trimming or finishing operations to remove.

This process involves 2 main stages. First, inject molten material, typically thermoplastic or thermosetting polymers, into a pre-designed mold cavity under high pressure and heat. Second, once the material cools and solidifies within the mold, the finished product is ejected. Depending on a specific item, the mold can produce one or many items per injection, which we call a number of gates per mold.

Several popular types of mold: two-plate mold, three-plate mold, hot runner mold, cold runner mold, multi-cavity mold.

BUENO can offer plastic engineering, injection molding parts, engineering plastic machining and rubber parts for injection molding.

Several popular types of injection machine: two-plate direct pressure type, all-electric type, hydraulic injection type

Plastic parts are produced by injecting a heated, liquid base material into a mold, clamping the mold until the material cools, and then ejecting the finished part. Short run molding has a few differences compared to standard production injection molds. For example, minimum quantities are lower, and with short run molding we can produce orders as low as 100 parts, no order is too small. Short run molding has a faster turnaround, which can reduce costs. Short run molding offers different mold options.Short run molding is attractive in a wide range of industries, including medical, automotive, and aerospace. It is an ideal choice for highly specialized parts that may need to be produced in small quantities. It is useful when precision and part performance are important.

Bueno provides Injection Parts especially items in flow control industry such as Valve Parts, Plastic Ball, Filler Piston, Bushing, Washer, Flange Cover, Valve Body and other OEM custom services.

Our injection molded blanks, composites, parts, tubing, as well as stock and complex shapes save time, ensure consistent quality and give your supply chain peace of mind when manufacturing and processing short-run injection molded 4000 complex shapes. Application industries include medical, automotive and aerospace, but our services are not limited to these areas.

Material Max Temp Chemical resistance Tensile strength (psi) Flexural strength (psi) Impact strength (ft-lb/in) Several Applications POM 180~230oC Excellent 6,000~ 22,000 120,000~ 170,00 0.8~2 automotive parts, valve ball, piston, bushing, wheels PP 65~148oC Excellent 4,500~ 18,500 210,000~ 1,500,000 1.4~5.5 food storage and packing HDPE 120oC Good to excellent 3,200~ 4,500 145,000~ 225,000 0.4~4 bottles, toys, bins, bushing LDPE 65~90oC Good to excellent 1,200~ 4,000 35,000~ 48,000 Not breakable bags, wrap, bottle, valve flange cover PBT 120~150oC Good to excellent 7,250~ 14,500 11,600~ 21,750 2.0~7.5 washer, rings, pistons, bearing, bushings, wheels, rollers PTFE 160~180oC Excellent 2,900~ 4,350 2,030~ 5,075 2.44~3.50 seals, gaskets, bearings, bushings in food process, industrial parts, medical device ABS 60~93oC Poor to fair 6,600 270,000~ 380,000 3.0~7.5 Parts in pipes, automotive body, keyboards. Nylon 93~177oC Good to excellent 6,000~ 24,000 390,000~ 1,100,000 2~8 Apparel, automotive, electrical parts, medical devices. PC 288~316oC Poor to fail 8,500 13,500 2~18 Electric parts, compact discs, telecom. hardware.

5. Wide Range Application: a wide range of application both daily life products and specific industries, such as in medical, home appliance & household items, cosmetic packaging, Electronic enclosures, Agriculture.

Firstly, we would like to offer an overview about Plastic Injection Process, its Pros & Cons, Materials and Applications in general.

2. Lead Time for Tooling: long lead time of the injection mold, several weeks to months, which may delay the start of production.

3. Design Flexibility: a high design flexibility, parts with as complex shapes, undercuts, and fine details, enabling engineers to optimize part designs for functionality, performance, and manufacturability.

Plastic Raw Material (Resin) significantly impacts the final product's properties, including strength, flexibility, durability, and appearance. Different plastics have instinct melting points, shrinkage rates, flow characteristics, and mechanical properties (tensile strength, impact resistance, elasticity…), which can affect how to design the mold, and how they behave during cooling and solidification.

Besides providing short run injection molded 4000 complex shapes, we are also a one stop shop for your coating & surface treatment, mold fabrication, polymer blending & fabrication, HTCM (High Temperature Compression Molding), extrusion, thermoforming, compression molding, and CNC machining needs.

Plastic Injection Parts are manufactured using the injection molding process, which is one of the most popular methods for producing plastic parts and components. In the process, the plastic injection parts can be mass-produced quickly and cost-efficiently.

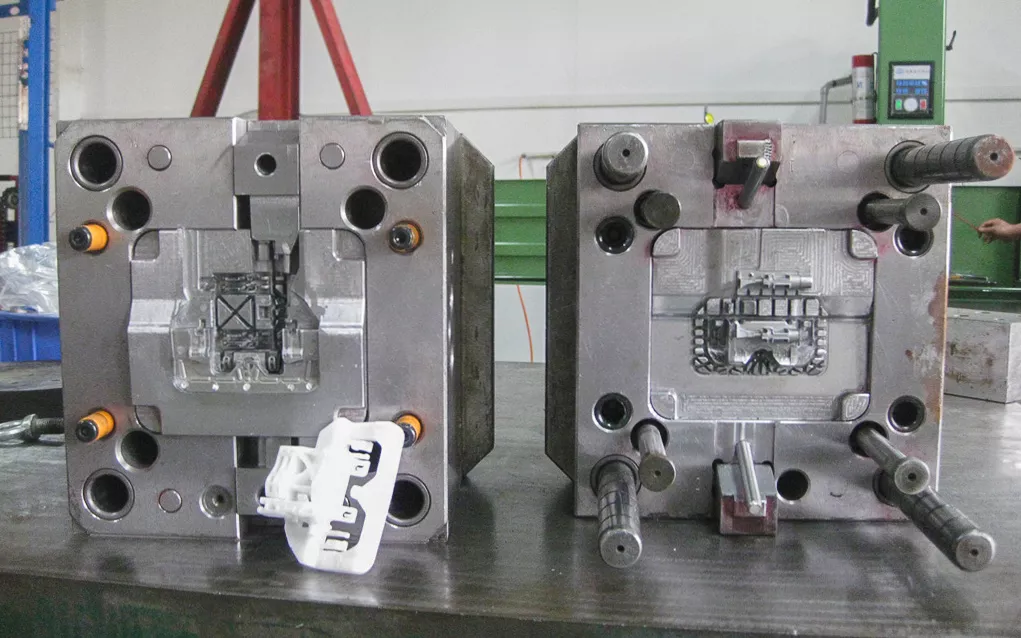

Elimold’s in-house injection mold making shop can design metal or plastic molds for injection molding manufacturing. We first design the molds using CAD files, and then use 5-axis cnc machining and EDM machining to turn them into reality. Once the molds are completed, we rigorously test the molds to ensure that the final product is flawless. Since we can provide one-stop injection molding services and have a dedicated injection molding shop to test the molds, we can also provide customers with sample, large and small batch production services. You don’t need to use your own machines or find a third-party company to do the injection molding for you, let us handle the manufacturing for you. It’s hard to find a company that is easy to work with when you need a fixed quantity of a product. At Elimold, we understand that you know your company best. We care about your bottom line budget and will provide the best quality molds and products for your company.

During the injection process, crystalline materials tend to solidify more slowly compared to amorphous materials, resulted in better flow, which can be advantageous for molding intricate or large parts.

1. High Initial Tooling Costs: perhaps expensive pre-designed molds (tooling), particularly for complex parts with intricate features.

In addition, crystalline materials typically exhibit higher shrinkage upon cooling compared to amorphous materials. Therefore, adjustments in mold design and process parameters may be necessary to compensate for this shrinkage and prevent defects like warping or dimensional inaccuracies.

Amorphous materials: lack a regular molecular structure, a random arrangement of polymer chains, resulting in solidifying more rapidly, shorter cycle times, making amorphous plastics suitable for simple design and high-volume production.

The design of the mold and the quality of tooling are critical factors in achieving desired injection molding part. The mold design determines the part's shape, dimensions, surface finish, and intricacies, while the tooling quality influences the precision and consistency of the molding process. Key considerations include gating and venting design, cooling system efficiency, draft angles, wall thickness uniformity, and parting line location. Poorly designed molds or inadequate tooling can lead to defects such as warping, sink marks, flash, or short shots.

Additionally, despite with the same machine, different parameters set up definitely affect the finished injection result. Thus, the injection molding process parameters must be carefully controlled to achieve optimal results. These parameters include injection pressure, injection speed, melt temperature, mold temperature, cooling time, and holding pressure and time etc.

2. Consistency and Precision: tight tolerances and high repeatability, ensuring consistent quality across large production runs.

Crystalline materials: with a highly ordered molecular structure, where polymer chains arrange themselves into regular crystalline regions.

We specialize in plastic injection molding. We are committed to providing the highest quality short-run and medium to high-volume plastic injection molding services. Elimold is a one-stop plastic injection molding shop that can manufacture, source, package and ship parts on time, even in an emergency. For your custom short-run plastic injection design or reverse engineering, our superior service and efficient production ensure timely delivery and excellent service.In addition to short-run plastic injection molding and reverse engineering, we also provide emergency manufacturing and delivery, engineering, PTFE processing, plastic plastic injection molding, PEEK processing, rubber molding and value-added manufacturing solutions.When designing custom short-run plastic injection molded parts, our staff assists customers through the entire life cycle, including customer input and design, prototyping (optional), tooling/mold production and production. We also make recommendations on seal modifications to facilitate assembly designs to help with installation, cleaning and repair.In addition, in an economy that requires balancing inventory and production, it is difficult to be prepared when unforeseen problems cause equipment to fail, lose power or overload. Elimold can help you avoid production losses. We work around the clock to ensure that your short-run plastic injection molding is completed on time while maintaining high quality and precision standards. Elimold can also assist you with new short-run injection molding designs and material selections. In addition to short-run injection molding, our value-added manufacturing also provides customers with a one-stop solution.

1. High Efficiency: high-volume production of identical parts with minimal material waste, highly automated, fast cycle times and efficient production, minimal Post-Processing.

4. Wide Material Selection: a wide range of thermoplastic and thermosetting materials, offering flexibility in material selection to meet specific performance requirements.

You can count on us to be ISO 9001 certified, with 4000 complex shapes for short-run injection molding, and your final product to be ASME, CSA, FDA, USDA, FSSC 22000, IATF 16949:2016, ISO 14001, ISO 26000, ITAE, Made in the USA, NSF, and UL certified. Our stock, cans, compounds, tubing, stock, and complex shapes help you succeed, including popular materials: PEEK, Nylon, Acetal, Polycarbonate, Polystyrene, Acrylic, PTFE, ABS, PVC.

Factors such as resin grade, additives, fillers, and colorants also play a role in determining the material's behavior during the molding process.

Plastic injection molding machines play a crucial role in determining the quality and consistency of injection molding results. Several factors related to the machine can affect the injection process and ultimately influence the quality of the molded parts such as: Clamping force, Injection Pressure and Speed, Injection Volume and Shot Size, Temperature Control & Cooling system.

Size ØA±0.7 ØB+0.7-0.7 ØC±0.7 ØD±0.7 ØE Type 150LB 300LB 150LB 300LB 150LB 300LB 150LB 300LB 150LB 150LB 300LB 1/2" 40 40 16.5 16.5 60.5 66.5 17 19 A A 3/4" 47 47 16.5 19.5 70 82.5 18 21 A A 1" 52 56 16.5 19.5 79.5 89 19 21 A A 1-1/4" 66 16.5 89.5 20 A 1-1/2" 75 75.5 16.5 22.5 98.5 114.5 20 24.5 28.5 C A 2" 95 96 19.5 19.5 120.5 127 23 28 41.4 C A 2" 95.5 19.5 120.5 23 A 2-1/2" 108 105 19 22 139.5 149 27 26.5 52.8 D B 3" 128 131 19 22 152.5 168 29 38 67.3 D A 4" 162 162 19 22 190.5 200 29 44 85 D A 5" 188 22 216 28.5 B A 6" 220 216 22 22 241.5 270 31 38.5 144.7 C A 8" 276 271 23 24 298.5 330 30 44.5 182.7 C B 10" 328 25.5 362 39.7 229.5 D 12" 381 25.5 432 38.6 B

Elimold understands that ten thousand pieces may not sound like a small order, but in fact, it is a significant order compared to the industry standard of one million pieces. Prototypes are produced quickly to a high standard to develop concepts and make them more affordable. Short-run injection molding is defined as beating the market. Niche markets such as small companies are profitable as small quantities of quality products are produced in small batches.These products are often only produced in a few hundred pieces. Design adjustments can be made before large quantities are produced, resulting in considerable gains.

Here at Elimold, we break down barriers to entry level plastic injection needs for prototypes or test runs. Short run or small batch injection molding is the same process of standard production molding without being cost prohibitive.Elimold is fully equipped and specializes in providing short run injection molded 4000 complex shapes.

Elimold’s team commitment is to provide innovative and consistent quality in plastics. Do you have a problem part/design? Send us what you have, we will take a look and offer up some advice. To begin collaboration on your next project, arrange a meeting or tour our facility.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly