Best Heat Resistant Plastic for CNC Machining - best plastics for machining

Author:gly Date: 2024-10-15

Thank you for your submission Your submission has been verified successfully. 11 0% https://www.baytechplastics.com/wp-content/plugins/nex-forms-express-wp-form-builderfalse/contact-thank-you/redirecthttps://www.baytechplastics.com/wp-admin/admin-ajax.phphttps://www.baytechplastics.com/do-you-need-custom-plastic-injection-molders-let-us-walk-you-through-the-processyes1fadeInfadeOut Submit

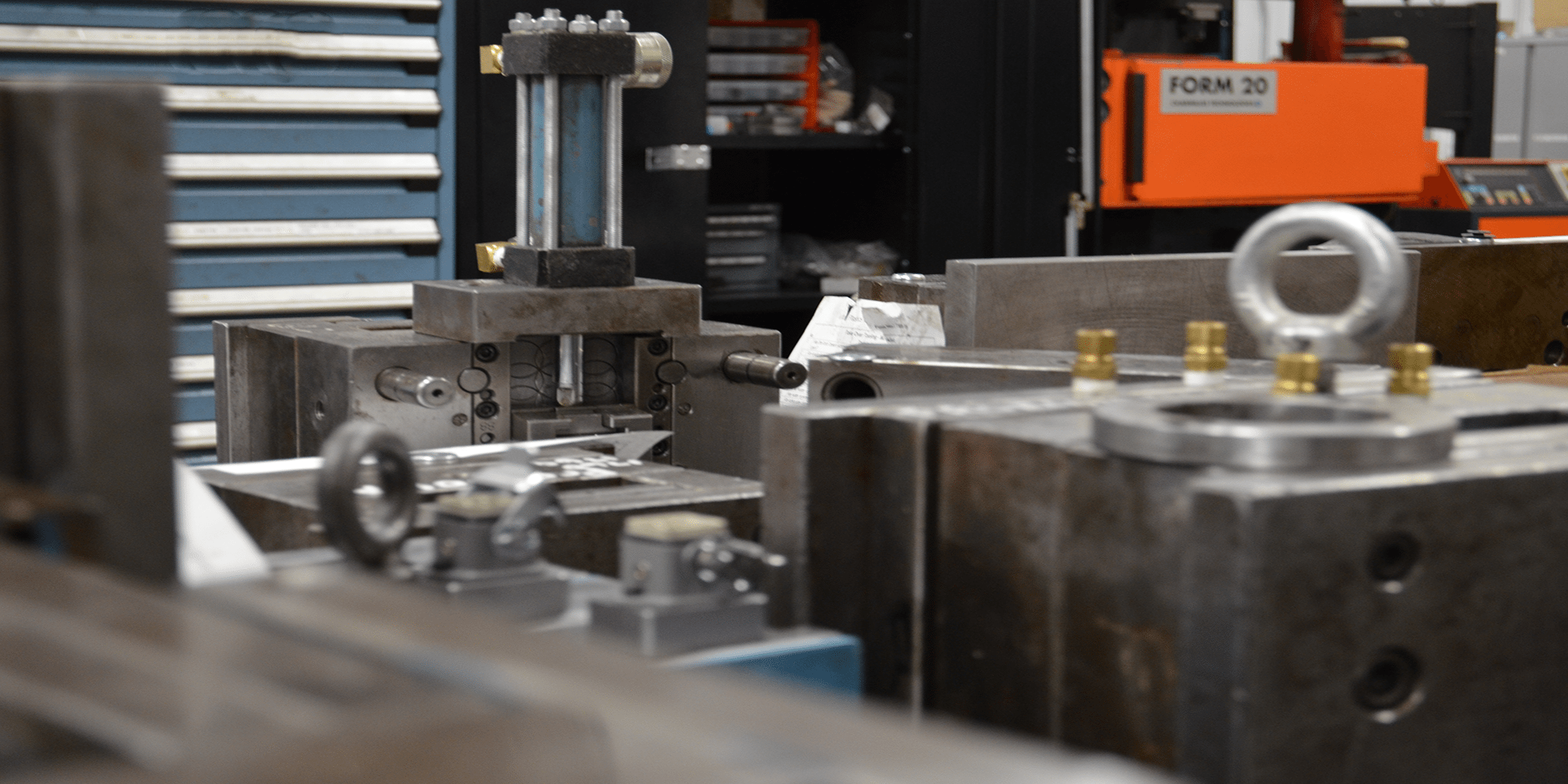

The concept of custom plastic injection molding is pretty simple. Liquefied plastic is poured or sprayed into a mold, sometimes under great pressure. The plastic is allowed to harden and, hooray, you have a finished product. Now this is not something you can do at home, at least on a large scale. There’s industrial equipment that both creates the custom plastic injection molds themselves and equipment that melts, injects and extrudes the plastic throughout the process.

– If so, choose a manufacturer that is close by. This will allow you to have both live and cyber meetings, which will help you to clarify your design and production run.

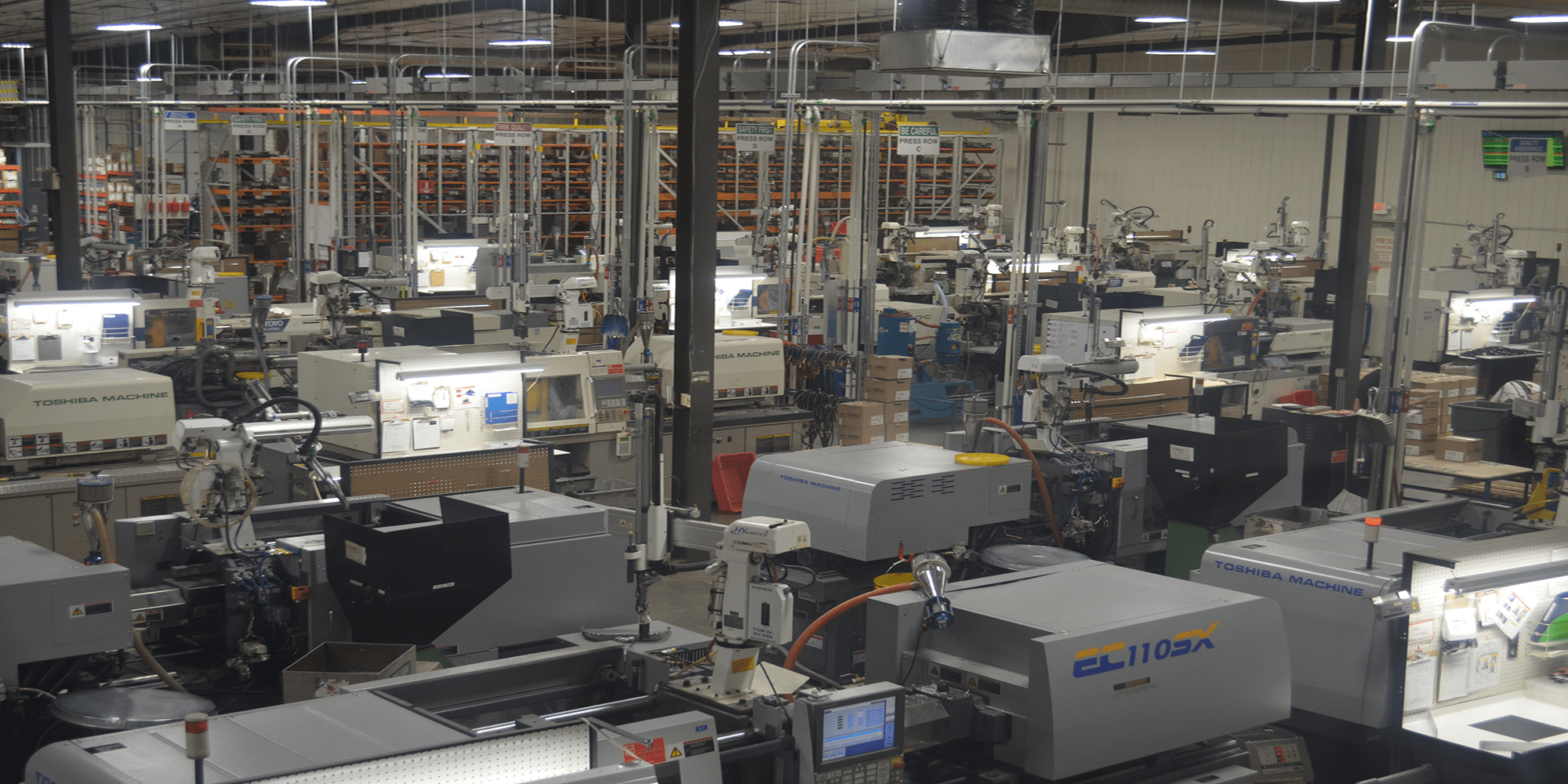

With over 50 all-electric presses, we have a wide range of custom injection molding solutions serving a range of strategic markets, Vital Plastics has been focused around providing customers with a comprehensive solution to their plastics needs. As technology and markets continue to evolve we stay committed to reinvesting back into our infrastructure and expanding our resources so we can always provide the best available value in the custom injection molding supply chain. Whether our customers have simple shoot and ship type of products, or comprehensive assembly and value add opportunities we welcome the opportunity to showcase our extensive engineering and technology services.

The old adage is true, time is indeed money. You need to establish a good rapport with your custom plastic injection molders, so you’ll know how long it will take to conceptualize, design, prototype, produce and deliver your product. You may have an amazing concept, and an even more amazing product, but if customers don’t get it on time, your efforts will have been in vain. Make sure you know and understand your manufacturer’s assembling, packing and shipping policies, so your product gets into the hands of your customers as soon as possible.

Baytech Plastics are Ontario’s premier custom plastic injection molders. We can guide you through every step of the design and production process, so your amazing concept will become the amazing product it was meant to be. Contact us today.

With nearly 70,000 sq. ft. of climate controlled manufacturing space, and an additional 6 acres of land for future growth, no project is too big or too small for our team to handle. We utilize all-electric injection molding machines, for process efficiency and consistency, ranging in size from 30T to 400T.

A plastic injection molding and contract assembly company providing customers with high value manufacturing services. Specializing in high-volume injection molding with the full complement of equipment including presses ranging in size from 30 tons to 400 tons capacity.

Vital Plastics is a plastic injection molding company with contract assembly capabilities dedicated to providing our customers with high value manufacturing services. We specialize in high volume injection molding with our full complement of equipment ranging in size from 30 tons to 400 tons capacity. From prototypes to production. Our number one goal is to exceed your injection molding & assembly requirements. We utilize Cellular Manufacturing for all of your plastic injection molded components, ensuring each part you receive gets the attention to detail you deserve. We also have more than 250 people on our assembly team, whether you need automatic, semi-automatic or hand-set assemblies.

Strategically located East of Minnesota’s Twin Cities metro area on Interstate I-94, Vital Plastics, Inc. is an industry leader in Thermoplastic Injection Molding and Contract Assembly. Since 1994, Vital Plastics is focused on providing above and beyond customer service, design & engineering assistance, and quality parts, on-time.

Our lives have been irrevocably changed by the invention of custom plastic injection molders. Think about it: water bottles, ladles, spatulas, tablet and phone covers and even the toys your child gets with their kids meal. These are all examples of everyday items that are brought to you by custom plastic injection molders.

Our large volume assembly services eliminate any middle men. This provides one resource and offers a cost effective solution. We utilize fully automated assembly machines we have bought or built ourselves as well as utilizing customer supplied equipment. In cases where the volume doesn’t warrant the expense of fully automated machines, we’ll utilize our semi-automatic equipment or hand-set assembly as a viable option.

Find a manufacturer that offers client support. Once you find a manufacturer you can trust, you’ll most likely go through a prototyping process where you’ll design a sample mold, then produce a few products to see how they look and function. Then you and your manufacturer will determine the resin and class of the mold you’ll need for the job.

We look forward to being your manufacturing partner on your journey to improve your efficiencies and your profitability. Our goal is to help unclutter your manufacturing floor; resulting in greater yields. With our two manufacturing facilities we are the perfect size. We’re large enough to handle your high-volume molding & assembly needs, yet small enough to focus on customer-specific requirements.

– This may seem like an odd question, but if you’re reselling products, it may be wise to choose a manufacturer closer to your client. Shipping parts or products to you, and then back to the customer may not be cost effective.

You may think that where your manufacturer is located is inconsequential, but that couldn’t be further from the truth. There are thee factors to consider here.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly