ASP Plastics: Home - plastic molding business

Author:gly Date: 2024-10-15

Topic: polymer manufacturing, injection molding, polymer components

Cap injection molding machines consist of several essential components, including the hopper, heating cylinder, screw, mold, and hydraulic system. The process starts with plastic granules being fed into the hopper and then melted in the heating cylinder. The melted plastic is then pushed through the screw, which melts and homogenizes the material. The screw then forces the melted plastic into the mold, where it is allowed to cool and solidify into the desired shape. Once the plastic has hardened, the mold opens, and the finished cap is removed. The hydraulic system controls the movement of the mold and ensures that the process runs smoothly.Cap injection molding machines play a crucial role in the production of caps and closures for various products. When choosing a cap injection molding machine, it is essential to consider factors such as production capacity, accuracy, energy efficiency, price, and brand. By considering these factors, you can ensure that you are getting the best machine for your production needs and budget constraints

We can provide a complete production line for making disposable syringes, Our products have the following advantages :High production efficiency: low noise: smooth gear transmission...

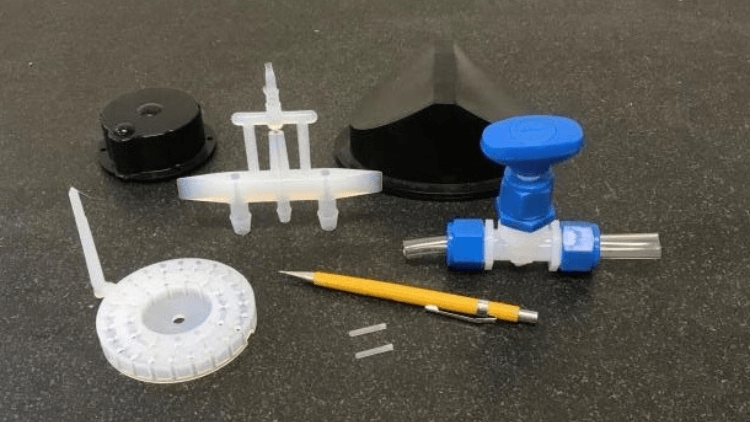

OEMs across industries have many options for producing plastic components built to handle critical challenges. However, the benefits and best use cases among them vary considerably.

Injection molding is remarkably versatile, and OEMs often gain efficiencies as well as cost savings over other plastic manufacturing processes. For OEMs with complex design requirements and no room for error, injection molding provides several advantages.

Looking for ideal High Speed Pet Injection Molding Machine Price ? We are the manufacturer of PET injection molding machine and have a wide selection at great prices.....

IML refers to in mold labeling. This molding technique is becoming more and more popular. Because in mold labeling technique can keep the pattern on the product all the time. We can get ready product with pattern after coming out from the mold....

Alternatives to injection molding include extrusion, blow molding, thermoforming, machining, and 3D printing – each with its own advantages. But if the project calls for precise capabilities, few processes deliver the quality and efficiency of injection molding.

In the injection molding process, machines inject molten polymer materials under high pressures and speeds into closed molds, resulting in high volumes of identical components that meet rigorous mechanical requirements.

Across industries and critical environments – from industrial and aerospace to automotive and medical – injection molding is a proven go-to solution. However, not all projects benefit from injection molding efficiencies. Projects that are ideal for injection molding typically involve:

In this blog post, we examine nine key characteristics of injection molding for complex polymer components. We also take a closer look at which projects are best suited for injection molding.

Looking for ideal High Speed Pet Injection Molding Machine Price ? We are the manufacturer of PET injection molding machine and have a wide selection at great prices...

A manufacturing partner with expertise across all phases of the process – from materials selection to part design and testing through to manufacturing – is essential to a successful outcome. When considering a partner, ask these questions:

Cap injection molding is a manufacturing process that is widely used for producing various types of caps and closures for different products such as bottled drinks, food containers, and personal care items. The process involves melting a plastic material and injecting it into a mold to produce the desired shape. Cap injection molding machines play a crucial role in this process as they determine the quality and efficiency of the end product. In this article, we will provide a comprehensive guide on cap injection molding machines, including their working principle, types, and key factors to consider when purchasing one.

Plastic injection molding offers diverse capabilities for a wide range of industries. In addition, advances in technology will continue to help manufacturers optimize the quality, sustainability, and adaptability of injection-molded parts.

We can provide a complete production line for making disposable syringes, Our products have the following advantages :High production efficiency: low noise: smooth gear transmission.....

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly