Arburg 221 KS 350 - 100 Injection moulding machine Used ... - arburg press

Author:gly Date: 2024-10-15

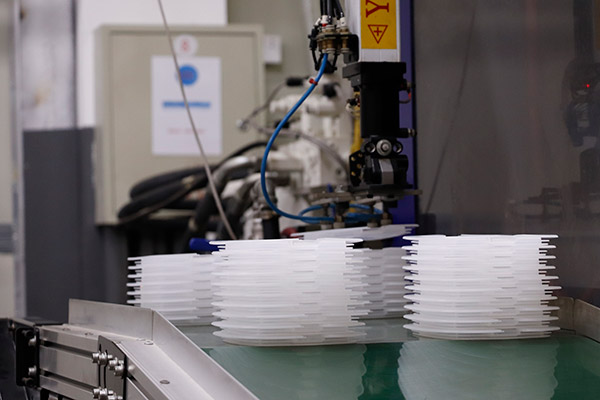

Once the manufacture of the tools is finished, we launch the production in our injection workshop. Our production lines are completely automated, and each batch is checked. Our expertise concerns as much injection as bi-injection; over-molding, gas assisted injection.

Injection molding means that the HDPE plastic is shaped by pressure in a heated mold. It is a very fast production method and the labor cost is low. It is popular with the production of smooth surface products in the production of complicated parts. Since we are working with a large number of injection equipment, our company is a competent company that fulfills the needs with the most affordable prices.

Specialist in plastic injection in China for more than 15 years. From the study to industrialization of parts and sub-assemblies, we can guarantee you secure, easy, qualitative and competitive cooperation.

Our integrated design office is in charge of the optimization of the part and the design of the plastic injection molds. It can intervene upstream of the prototyping phase.

In general, HDPE injection has 700-2000 kgf / cm² pressure, 160-250ºC temperature and 10-30 seconds production time. There are different injection devices that produce many products including the smallest parts, and the largest plastic parts. The hot runner system is used in injection molding for reducing the need for the material, labor and machine capacity.

We provide different finishing operations (marking, stamping, screen printing, etc.) and the decoration of injected plastic parts to give the desired appearance.

Upstream of series production, we offer different fast prototyping technologies. These prototypes allow us to test a pre-series, and to perform visual, functional and mechanical tests.

We work with all types of thermoplastic and elastomer materials according to customer specifications: ABS, PC, PMMA, TPE, PA, TPU, POM etc., with or without loading. We master different injection processes depending on the characteristics of the parts to inject. Our design office, a department central to our organization, ensures the optimization of the part whether it is at the prototyping or the molding by injection stage. In addition, it takes charge of the design of the plastic injection molds and the 3D drawings will be given to you. The molds will be manufactured in our tooling workshop and maintained in our dedicated and laid-out storage room.

There are no good parts without good injection tools. You invest in a quality mold made to European standards. The design, the manufacture and the maintenance are performed internally in our mold workshop. We guarantee the servicing.

In the HDPE production market, the products that are produced with injection molding technique constitute 30% of total production. HDPE injection products, which are used in many areas, lead the market since they provide many advantages. The melting of HDPE by the heat and shaping it in the injection machine is the most common method for producing plastic materials. The process consists of closing, injection, ironing, cooling, mold opening and removal from the mould. Every stage is performed automatically and the finished part is removed from the mold during the extraction process.

Nous utilisons des cookies pour optimiser notre site web et notre service.Conformément à vos choix, certains partenaires et nous pouvons accéder à votre terminal pour vous reconnaître via des traceurs comme des cookies, collecter, stocker, croiser, et transférer des données comme vos adresses IP et email, vos paramètres de logiciels, votre navigation ou votre localisation, à ces fins : Publicités standards et mesure de performance des publicités, Profil de publicités personnalisées et affichage, Contenu personnalisé et Mesure de performances du contenu, données d'audience, et développement produit.Nous vous en remercions et vous proposons d'appliquer vos choix à ces partenaires également. Vous pouvez bien sûr refuser leurs traceurs et traitements.

We have started our journey in 2012 to facilitate our customers’ lives and to offer many opportunities that would enrich your lives. Over time, we have developed ourselves and have succeeded in becoming a respectable, reliable and global company in the petrochemical sector, after increasing our resources and enhancing our product range.

HDPE injection material is used in the production of covers, cases, plastic pallets, kitchen items, toys and many other products and this is a high density polyethylene material. With the injection molding, the HDPE takes every shape. Since the values of temperatures and pressure value depending on the product, it can be widely used.

Expert in plastics injection molding, in our workshop in China we produce all types of plastic technical and appearance parts from small runs to mass production. We have fully automated injection presses from 70 to 1200T. The injected parts can then be assembled on our assembly lines and finalized by various finishing and decoration operations (metalizing, painting, inserts, etc.).

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly