APSX, LLC. - apsx injection molding

Author:gly Date: 2024-10-15

To get your components or sub-assemblies manufactured by us, you can call our team on 01543 462 561 or send an email enquiry to [email protected]. Our team of experts will be in contact within hours to help you with your project.

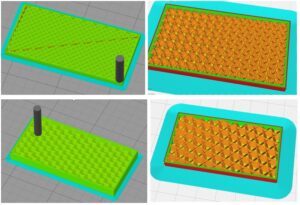

Exploring the Fascinating World of Infill Patterns in 3D Printing 3D printing has revolutionized the way we create objects, allowing us to transform digital designs into

Exploring the Best 3D Printing Settings for HIPS High Impact Polystyrene or HIPS is a standout choice in the world of 3D printing. Known for

3. Enhanced Corporate Image: Embracing recycled plastics showcases a commitment to environmental responsibility, enhancing brand reputation and resonating with conscientious consumers.

100 Innovative 3D Print Projects You’ll Love Introduction In the ever-evolving world of technology, 3D printing stands out as a revolutionary tool that empowers creators,

Let’s delve into real-world examples of manufacturers overcoming challenges. In a recent case study, a forward-thinking company integrated recycled plastics into their injection moulding processes, witnessing a 20% reduction in material costs without compromising product quality. These success stories underscore the tangible benefits awaiting those willing to embrace change.

One common hurdle is the perception that recycled plastics compromise product quality. Allow me to dispel this myth. Technological advancements have elevated the quality of recycled plastics, ensuring they meet or exceed the standards set by their virgin counterparts.

1. Reduced Environmental Footprint: Utilising recycled plastics significantly diminishes the demand for new raw materials, alleviating the strain on our ecosystems.

Enhancing Electronic Products with Vacuum Casting Technology In the fast-paced world of electronics, precision and quality are paramount. The demand for innovative and reliable electronic

Exploring Metal Filament 3D Printing: The Future of Additive Manufacturing Introduction In the ever-evolving landscape of 3D printing, metal filament 3D printing has emerged as

Two-shot molding, also known as two-component molding or 2K molding, is a process that involves injecting two different materials into a single mold to produce a finished part. The two materials are typically different types of plastics or a combination of plastic and a different material, such as rubber or metal. Key points about two-shot molding include:

FreeCAD vs. Autodesk Fusion®: Which CAD Software Reigns Supreme? When it comes to computer-aided design (CAD) software, two names often come up: FreeCAD and Autodesk

While the initial investment in transitioning to recycled plastics may raise concerns, conducting a thorough cost analysis reveals the long-term savings potential. Factor in reduced material costs, potential tax incentives for sustainable practices, and the positive impact on brand perception.

Undoubtedly, the environmental impact of traditional plastic manufacturing cannot be ignored. The proliferation of plastic waste has reached alarming levels, prompting global concern and stringent regulations. As manufacturers, we hold a pivotal role in steering the industry towards eco-friendly practices.

In conclusion, the journey of recycled plastics in injection moulding is a testament to the industry’s adaptability and resilience. As we stand at the intersection of environmental consciousness and manufacturing innovation, the decision to embrace recycled plastics is not just a choice; it’s a commitment to a future where waste is minimised, and opportunities are maximised.

I urge manufacturers, particularly those with a keen eye on sustainability, to consider the transformative power of recycled plastics. In doing so, we not only safeguard the environment but also future-proof our businesses, ensuring they thrive in a world that values ecological responsibility.

The Best CAD Software for 3D Printing: A Comprehensive Guide In the dynamic world of 3D printing, choosing the right CAD (Computer-Aided Design) software is

Navigating the regulatory landscape is a concern for every conscientious manufacturer. However, the use of recycled plastics aligns seamlessly with existing environmental standards and often exceeds compliance requirements. This alignment not only ensures legal adherence but also positions the company as a responsible industry leader.

In the dynamic landscape of manufacturing, the call for environmental sustainability has become increasingly resonant. As a seasoned professional in the field of plastic injection moulding, I am eager to guide environmentally conscious manufacturers, on the transformative journey of incorporating recycled plastics into their injection moulding processes.

I recall a project where initial scepticism was replaced by amazement as a state-of-the-art injection moulding machine effortlessly processed recycled plastics, producing components of exceptional quality. Technological progress is propelling the industry towards a future where recycled plastics are not just viable but preferable.

Best Dual Extruder 3D Printers in 2024 3D printing technology continues to evolve rapidly, offering new capabilities and enhanced performance. One of the most significant

CREO vs. SolidWorks®: A Comprehensive Software Comparison In the world of computer-aided design (CAD), two names frequently rise to the forefront: CREO and SolidWorks®. Both

Keep posted on the release of Coupon Code. The latest news of 3D Printing, CNC Machining, Injection Molding, and Silicone Molding…

Looking ahead, the future of recycled plastics in injection moulding is teeming with possibilities. Researchers and industry experts are exploring innovative methods to enhance the performance of recycled materials, opening doors to even more sustainable practices.

Overmolding, also referred to as insert molding, is a process in which a second material is molded over a preformed substrate or insert. The substrate can be made of various materials, such as metal, plastic, or even another molded part. Key points about overmolding include:

Injection molding is a widely used manufacturing process that allows for the production of complex and precise plastic parts. Two variations of injection molding, two-shot molding and overmolding, offer unique capabilities and advantages. In this blog post, we will explore the differences between two-shot molding and overmolding, helping you understand when and how each technique is used in the manufacturing industry.

During my tenure, I’ve observed that regulatory compliance, when approached as an opportunity rather than a burden, fosters long-term business sustainability. Adhering to eco-friendly practices is not merely a legal requirement; it is an investment in the company’s future resilience.

Exploring the Best Desktop CNC Milling Machines In recent years, desktop CNC milling machines have revolutionized the way hobbyists, makers, and professionals approach fabrication. These

Mould design plays a crucial role in the successful implementation of recycled plastics. Consult with experienced mould designers who understand the unique characteristics of recycled materials. Adjustments may be necessary to optimise the performance of recycled plastics in the moulding process.

Two-shot molding and overmolding are both valuable techniques in injection molding, offering opportunities to create complex, multi-material parts with enhanced functionality and aesthetics. Two-shot molding enables the bonding of two different materials during a sequential injection process, while overmolding involves adding a second material over a preformed substrate. Understanding the differences between these techniques will help manufacturers choose the most suitable approach for their specific applications, taking into account design requirements, material combinations, and process complexity. By leveraging the capabilities of two-shot molding and overmolding, manufacturers can achieve innovative solutions and differentiate their products in today’s competitive market.

Transitioning to recycled plastics requires a strategic approach. Begin by conducting a comprehensive assessment of your current processes and materials. Identify suitable recycled plastics for your specific applications and gradually integrate them into your production line.

As industry leaders, we bear a collective responsibility to shape a sustainable future. Collaboration, knowledge-sharing, and the pursuit of cutting-edge technologies will define the next chapter in injection moulding. By fostering an environment of continuous improvement, we ensure the longevity of our industry and the planet.

In these success stories, there is a common thread of adaptability, open-mindedness, and a willingness to experiment. Embracing recycled plastics requires a cultural shift within the organisation, with employees at all levels understanding and championing the cause.

Recycled plastics offer a compelling alternative, addressing both environmental concerns and the need for sustainable manufacturing. Contrary to misconceptions, recycled plastics have evolved into high-quality materials suitable for injection moulding, offering a plethora of advantages.

Quantifiable benefits extend beyond cost reduction. Improved product quality, a significant decrease in waste generation, and a positive response from consumers all contribute to the success of manufacturers embracing recycled plastics.

The Future of Automotive Parts: How 3D Printing is Transforming the Industry In the fast-paced world of automotive manufacturing, innovation is key to staying ahead

We can advise on the design of your product to suit the manufacturing processes required. We can organise tooling for you and manage the project for you so that you receive conforming parts at a competitive price. And we’ll keep doing that for you for as many years as you need us to.

IN3DTEC rapidly delivers prototyping & scaled production on demand to help project designers and engineers accelerate new product introduction. We make excellent products from your ideas.

Exploring Shapeways Alternatives: Finding the Right 3D Printing Service for You In the rapidly evolving world of 3D printing, Shapeways has established itself as a prominent

Allow me to share a notable success story from my own experience. A mid-sized manufacturing firm, initially hesitant to adopt recycled plastics, witnessed a remarkable transformation. After implementing recycled materials, they not only contributed to environmental conservation but also experienced a 15% reduction in production costs.

2. Cost Efficiency: Recycled plastics often come at a lower cost, providing manufacturers with a competitive edge while contributing to overall cost reduction.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly