Applications of Engineering Plastic POM Injection Molded ... - pom injection

Author:gly Date: 2024-10-15

Cases, cowlings and hulls are examples of parts that we produce very regularly. In a field that requires many tests and certificates, such as the medical sector, the plastic injection can satisfy the regulatory requirements and constraints. (Find out more on our page about standards.)

Parts of the car that require plastic components in two different colors can be made using double injection molds of different shapes and sizes.

At RYDTOOLING we use the highest quality thermoplastics and other raw materials to ensure that the two-shot molds stand the test of time and use. Our rigorous quality checks at all stages of the injection molding process ensure that our end product is error-free.

Thank you for your comment. We would only need the CAD design of the toothbrush, CAD design of mold would be done by us. On of our project manager will reach to you by email to have more information about you injection molding project.

Medical equipment, streetlights, and various consumer products require thermoplastic components that can be manufactured using 2k molds.

The ‘prototype mold’, or ‘rapid plastic injection tooling’ is based on the same principle as series plastic injection molds, but has a simplified and accelerated design. It is also not intended for long-term use. The use of a common mold base and aluminum for the molding parts makes it possible to reduce investment costs and machining time. Production of the prototyping mold takes between 2 and 4 weeks and is 40 to 60% less expensive than a traditional mold. The cost and design time of the mold depends on the shape complexity of the part to be molded. After a complete analysis of your plastic parts, our design office creates the tooling plan of your mold. We then start its production according to your specifications.

Our design team is one of the best you will ever come across. We don’t just focus on the functionalities and performance of the 2k molds; we also make sure they look their best because we understand the image is everything.

Our 2k molds are among the most sought after in the industry and are used in many different kinds of industries including:

RYDTOOLING multi-color injection molding begins with concept design and renderings of the component you want to manufacture. Next we use rapid prototyping and 3D printing to show you what your design will look like in real life. Based on your critique we tweak the design and create a 2K mold that matches your requirements exactly. Finally, we use our 14 injection molding machines ranging from 86 tons to 1,600 tons to provide plastic injection molding services to make all kinds of different components.

Electrical components that require complex mechanical and electronic segments can use two shot molds to create these components.

Thermoplastics are the backbone of any molding process. The process of double injection molding requires heating the plastic components again and again without damaging the integrity of the material. This is why the quality of thermoplastics used in 2k molding is very important.

Hello, I have 3D drawings for a project. I would like a quote for injection molding or your prototype mold system. Thank you

RYDTOOLING has been around for close to 15 years, amassing valuable experience through those years that puts us in the correct position to handle all your mold needs. We have a team of qualified experts who are well versed with all the two-shot injection molding techniques. You are assured of getting exactly what you need.

This technique allows the production of small series that are close to reality. The applications of plastic injection molding are very varied. They are particularly useful in the automotive, packaging, medical, and electronics sectors.

Our rapid plastic injection molding solutions are specially adapted to the production of prototypes and small series of plastic parts (from 100 to 1000+ parts). Inspired by traditional molding techniques, we inject your plastic parts using an aluminum prototype mold (or rapid tooling). The results achieved with this technique are equivalent to series molds. The robustness, mechanical properties and industrialization information are identical.

The design of our injection rapid tooling is based on a standard ‘mold base’ frame and interchangeable aluminum core and cavity inserts. This reduces the investment costs and production times inherent in plastic injection. This is our rapid production technique which is the most expensive. However, it makes it possible to obtain functional parts made from the ‘right material’. They can be marketed or used in transition production.

Thank you for you comment. We would need you specifications to advice and quote you : CAD files, volume required, material etc.

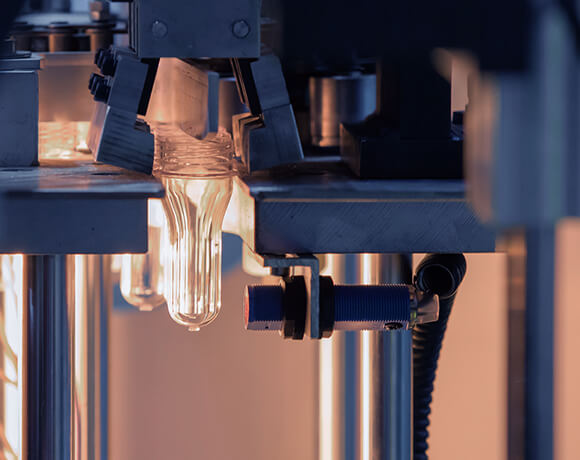

This process consists of injecting a molten polymer (thermoplastic material) into the prototype tooling under high pressure. The plastic material is then cooled and solidifies, taking on the shape of your part. This prototyping technique allows the use of a very large range of ‘right material’ resins. The overmolding of metal inserts and the production of parts incorporating two materials is possible.

The 2 shot molds from our assembly lines have all the attributes needed to make them work as efficiently as advertised. The good drips on the molds allow you to use them in a wide range of applications, depending on your needs.

2k molding process allows you to use a single tool to fabricate several components. This automation process reduces the operational costs, and the need for labor also goes down significantly. 2k injection molding process involves piping thermoplastics inside the mold and heating them, waiting for them to cool and then taking the finished product out.

In rapid prototyping, the use of a prototype mold for plastic injection, therefore, makes it possible to obtain small series using the right material at a lower cost and in reduced time. It is a very good solution for testing your concept quickly and cheaply. There is no need to sacrifice the quality of the final part. You, therefore, obtain reliable information (mechanical, geometric, assembly and industrialization) on the final parts as well as the subsequent production of a series injection mold.

Thank you for your comment. Best format would be : STP / IGS / XT. I you could provide one of these please we could quote your project.

We are always in touch with our clients through the whole designing process, incorporating the feedback along the way to give a complete end product that checks all the boxes. Doing things halfway is not how we do things at RYDTOOLING. We commit to a project to the end.

All appliances need some plastic components that are not only functional but have cosmetic appeal as well. 2k molds can help create these parts.

Twin injection molding is a process where a two-shot injection is used to produce custom plastic parts with two or more plastic resins of different colors in a single operation for a specific function. The main aim of this process is to create products with better structural integrity for a wide range of uses.

Being the best in the industry doesn’t come by luck; we have invested in technology and state-of-the-art machinery to ensure our clients get the very best for their manufacturing needs. Working with us opens you up to some of the following advantages

Two shot injection molding is an efficient way to produce custom plastic parts with two or more plastic resins or colors in one operation to achieve a specific function. The process is also referred to as transfer molding, 2k molding, two-color injection molding, multi-color injection molding, 2-component injection molding, and the like.

You get the best value for your money through the use of our versatile products that can be used in different ways. Creating versatile tools is our biggest motivation as we are driven by the need to create convenient solutions for our clients.

Your B2B needs are also well covered by our services. At RYDTOOLING, we understand the importance of forging partnerships and the challenges of running a business. We offer good discounts on bulk purchases for our most loyal clients to help them hit the road running. Continued support is the core of our business.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly