ABS Injection Molding: Know Its Process and Advantages - abs molding

Author:gly Date: 2024-10-15

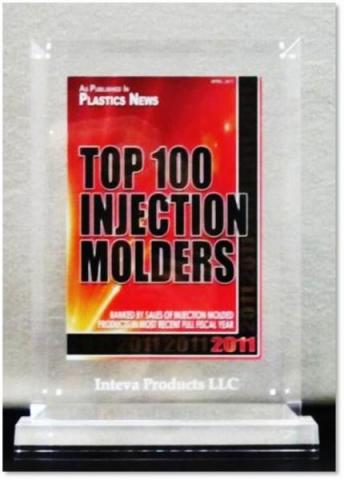

Plastic News magazine reviewed over 500 companies with injection molding capabilities and Inteva Products ranked in the top 20, earning Inteva a Top 100 Injection Molders Honor. Companies are ranked by sales of injection molded products in the most recent full fiscal year. Plastic News is a noted authority and is the largest circulation magazine among all plastic publications.

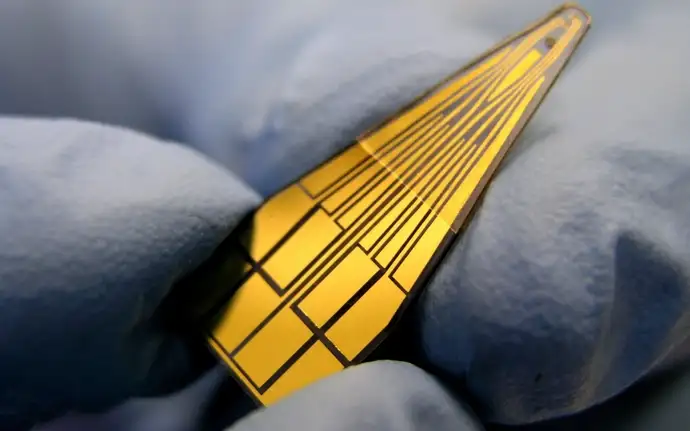

We understand that achieving optimal product performance begins with selecting the right molding technique early in the design phase. At SCHOTT MINIFAB, we ensure that our clients have access to the precise tools needed to bring their innovative designs to life. From standard to precision, vario-thermal, and 2K injection molding, we offer a diverse suite of molding technologies, chosen to address specific project requirements. Explore our table below for a comparison of features across different molding techniques.

As a contract manufacturer of diagnostics and life science research consumables, we go from pilot line to high volume quickly and efficiently.

SCHOTT MINIFAB is a global leader in precision injection molding. We excel at delivering parts with precision features and tight tolerances. We focus on high-volume products for regulated markets where quality is non-negotiable.

Choose SCHOTT MINIFAB for precision injection molding, without compromise. Request a quote or kick off your project by consulting with one of our engineering experts.

We specialize in Design for Injection Molding (DFIM), ensuring optimal manufacturability and part quality. As an ISO-certified provider of engineering and custom injection molding, we prioritize DFIM to mitigate risks like wall thickness issues and part damage from ejection methods, resulting in smoother production and higher-quality outcomes. Our approach integrates DFIM into the product development process, optimizing designs to reduce costs, simplify production, and enhance overall quality. Our expert engineers collaborate closely with clients to anticipate issues and maintain design intent, ensuring seamless execution and superior results.

To protect your privacy, external content will only be loaded with your consent. Refer to our Cookie Policy for detailed information.

High quality tooling ensures the precise and consistent production of molded parts. Our in-house team of tooling experts specializes in injection molding design, mold flow analysis and tooling for microfluidic applications. Using advanced tooling technologies, the tooling team can develop molds with complex geometries, tight tolerances, and intricate designs, specifically for industries that demand a high degree of quality and precision.

Our advanced infrastructure redefines industry standards, with robust capacity, stringent certifications, and precision-driven automation for unparalleled efficiency and consistency in injection molding.

We offer a wide array of materials for your injection molding needs: Polycarbonates (PC) Polymethyl Methacrylate (PMMA) Polypropylene (PP) Cyclic Olefin Copolymer (COC) Cyclo Olefin Polymer (COP) Thermoplastic elastomers (TPE) with 2K Compatibility Styrene-ethylene-butylene-styrene (SEBS) ...and more, if you have a specific need let's discuss.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly