ABC Plastics - abc plastic moulding

Author:gly Date: 2024-10-15

For plastic molded components, we give our customers a variety of molding options along with project control and design flexibility. We work closely with our customers to make decisions regarding material choice; weight, durability, strength, cost-effectiveness, or all of these. Finally, we will review the moldability of your part and provide you with design for manufacturability feedback to ensure your mold/molded parts are completed on time, within budget, and meet all other specifications.

Looking to collaborate with us? Click here to get in touch with us now! You may also view our list of products and services here, as well as, our list of available equipment.

We continue to strive to develop a relationship with our customers that is based on mutual trust and a commitment to do the right thing in the right way. Our employees are involved in the process so they understand and are invested in the needs of our customers; taking pride in completing a project and having a satisfied customer as the end result.

At Plas-Tech Tooling, we offer our customers the unique experience of working with a company that provides both production machining and plastic injection molding. These capabilities give you plenty of flexibility when it comes to material selection for your manufacturing processes.

Please describe the project you would like quoted with as much information as possible. We will respond with a no obligation quote usually within 1-2 business days.

Plas-Tech offers CAD Drafting services, or we can work directly from your print. We can design either simple or complex molds, test the tooling and even provide sample parts before a production run.

Thank you for considering us for your manufacturing demands. Our goal is 100% on time delivery, 100% right first time components, and 100% customer satisfaction.

At Richfields, our time-testing large plastic molding solutions have allowed us to cater to different industries. Aside from specializing in small plastic consumer goods, such as safety products, we also work with clients in the fields of automotive, industrial, petrochemical, food & beverage, and many more.

From a single machined or injection molded part to an assembly or weldment requiring coatings and more, let Plas-Tech Tooling quote your project. We will find a solution that is right for you. No job is too big or too small.

Since 1993, we have been partnering with our customers to provide them with turnkey manufacturing solutions through production machining and plastic injection molding services. Our goal has always been to make their lives easier, saving them both time and money! Call us today!

Plas-Tech Tooling is a dedicated to providing high quality manufacturing solutions to customers across a wide range of industries. We strive to partner with our customers to provide the best possible solutions.

We recognize you have a multitude of choices when it comes to selecting the right CNC machining supplier. Our customers are accustomed to relying on us to deliver small and high-volume metal or plastic parts that are critical to keeping their lines moving. With the capabilities of a large machine shop and the flexibility, customer service and responsiveness of a small one, we work directly with our customers to provide creative, cost-effective and timely solutions to every project.

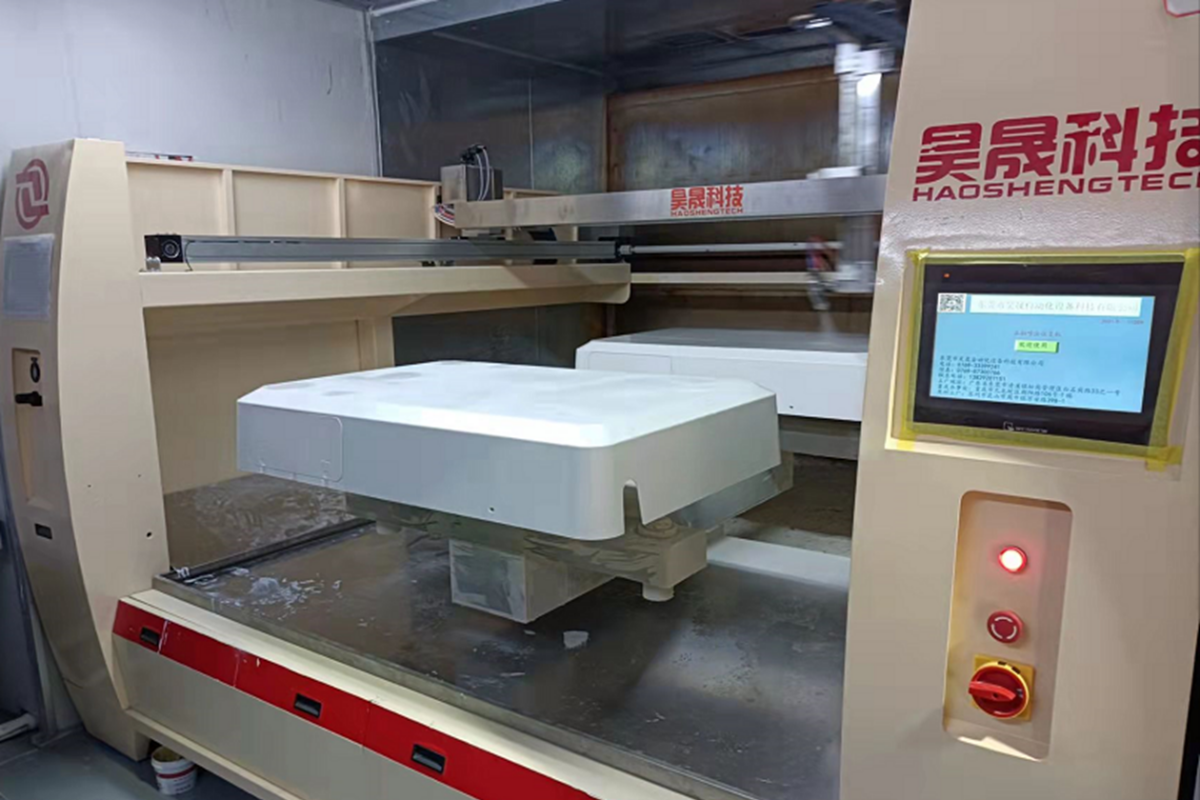

As the name suggests, large size plastic injection molds are molds that are capable of creating large plastic parts — whether it be customized, or OEM-grade goods (Original Equipment Manufacturer).

Designing large size molds is not something that every molding company can achieve. A contributing factor to this is the machinery, expertise, and process requirements. For example, crafting molds for large size plastic products needs to undergo proper mold flow analysis to ensure that the resin will reach the mold cavities. Manufacturers may also conduct various testing methods to ensure quality of the mold.

We are so much more than a machine shop offering small or large production runs. We listen and respond to your need for prototypes and emergency services, and can make transition to full production when the time is right. We are confident in the quality of our parts because the high-speed machinery provides you with components without compromising the dimensional stability of your parts.

Richfields Plastics has been the forefront in the mass-production of large size plastic injection molds. For several decades, our molding company in China has been delivering only the best and most reliable solutions for different finished plastic parts.

At Richfields Plastics, we not only guarantee high-quality steel or hardened steel molds — we also ensure that you’re getting what you pay for. We will be able to provide you with an estimate based on the kind of features that you need for the final part. Do you need basic, advanced, or intermediate rapid prototyping or insert tooling? Simply tell us what you want your mold to look like and we will undertake the necessary prerequisites and pre-design procedures that can transform your initial mold design into reality.

My wife and I started Plas-Tech in 1993 in a 2 stall garage and built our first building at our current location in 1996. Since that time, Plas-Tech has grown to 21.000 sq. feet and we have a great staff of 25 full and part-time employees. Building a business required long hours, hard work, and a determination to satisfy our customer’s needs by providing on-time, cost-effective machining services.

All of these prerequisites are critical in determining the success of the project and preventing any injection molding issues that will lead to failure. If you already have a prototype for the mold, our experts at Richfields Plastics can help you optimize it better, achieve part success, and come up with a final plastic part that meets your satisfaction. Read on to learn more.

Aside from the automotive sector, we’ve also been able to produce a number of designs for electronic products, industrial storage systems, tools, and sports equipment. Versatile, dependable, and matured — our large size mold manufacturing operations continue to offer value and reliability to all our customers and professional clients.

When your equipment breaks down, we are here to get you back up and running quickly with our emergency machining services. We will work with your team to come up with a solution.

— Finally, we will provide a no obligation quote. Depending on the information provided and project complexity, quotes may be provided in as little as a few hours.

The prices for our large size injection molding services rival that of our competitors. Mold tooling for large plastic parts can be expensive, depending on the size, raw materials, repair costs, and other requirements. In fact, even just a single-cavity mold may cost anywhere between $1,000 and $5,000. Family or multi-cavity molds on the other hand, may fetch for more than 70 times the price — at $80,000.

However, don’t let these figures discourage you — although they may seem costly initially, you also have to take into account the lifecycle of the product. Some manufacturers may promise cheap molds, but the downside is that they may not necessarily be capable of achieving tight tolerances and high-quality parts.

Typically, any large size plastic mold can be classified according to weight — this could range from 50 tons to as much as 2,100 tons, depending on machine availability. With this in mind, you have to make sure that you partner with a leading molding firm like us. Here at Richfields Plastics, our mature supply chain and capacity to provide large size molds to various industries make us the go-to large size mold manufacturer. Our flexibility, price competitiveness, and commitment to industrial plastic molding quality remains unparalleled in the industry.

Our flexibility means that we can create large size mold prototypes for virtually all kinds of product assembly. We have served a number of car manufacturers, for example, in designing high-quality car bumpers that exceed safety standards and regulations in the industry. Using specialty resins, reinforced plastics, and other types of rubbers, we have been able to mass produce different bumper designs that fit well with the rest of the vehicle.

Our advanced machining capabilities along with our technical know-how, allows us to effectively manage complex projects of various sizes, weights, materials and surface finishes. We take great pride in our value-added services such as assembly, kitting, welding, inventory management, drafting services and more.

In any large plastic injection molding project, the customer has to look at the molding firm’s capabilities. Do they have the right machinery to produce the molds? Can they provide insights regarding the success of the mold? Will they be able to achieve tight part tolerances? Asking all of these questions is important because you ultimately want to choose a molding company in China that can offer you the right mold designs at a reasonable value/price range.

Looking for a molding company in China that can produce large size plastic injection molds? Here at Richfields Plastics, we have all the capabilities to provide you molding solutions ideal for large designs. Whether it’s for an automotive component, construction part, or any plastic mold that’s bigger than your typical molded product, our well-developed business model and team of resin experts can help you out.

At Plas-Tech Tooling, we offer our customers the unique experience of working with a company that provides both production machining and plastic injection molding. These capabilities give you plenty of flexibility when it comes to material selection for your manufacturing processes.

Central to any large size plastic injection mold-making process is the equipment. At Richfields Plastics, our factory houses multiple units of CNC, EDM, wire cut EDM, lathe, gun drilling, and drilling machines to fabricate high-quality molds made out of steel.

Each mold is cut to size, according to your industrial preferences. Using only the finest and highest grade raw alloy/metal materials out there, our molds are designed to last for several decades, with only minimal maintenance required.

Demonstrated the ability to help customers overcome obstacles such as unrealistic due dates with multiple revisions while working with designers in several countries.

— Plas-Tech will review the information and request more as needed. We will also provide any feedback that may help improve your part.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly