11 Most Popular Injection Molding Materials - plastics that can be injection mou

Author:gly Date: 2024-10-15

Production molds are high cavitation SPI Class 101 and 102 molds constructed from hardened steel. Cold runner, hot sprue, and hot runner molds are designed with up to 128 cavities.

Our assembly and joining capabilities include product filling, foil/heat sealing, ultrasonic welding, heat staking, mechanical assembly, pinning & UV/hot melt gluing, custom packaging/kitting, and pouching.

Not all mold makers are the same. We are an ISO-certified, family-owned provider of engineering, custom injection molding, and contract manufacturing services. Our clients bring demanding applications best served by expert engineers and manufacturers.

We take pride in being the leader of mold makers. All Natech tools and production parts are made in the USA. We run three shifts per day, five days per week, and weekends are run on an as-needed basis.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

Hot Runner Temperature Controller also called HRTC in short form. Hot runner temperature controller is used to run mainly Plastic Injection Molding Machine's molds. Let's try to understand 2 main types of molds. Hot Runner vs Cold Runner Injection Mold: Key Differences You Need to Know   Home Blog Hot Runner vs Cold Runner Injection Mold: Key Differences You Need to Know Hot Runner vs Cold Runner Injection Mold: Key Differences You Need to Know Updated: October 17, 2022 An injection mold is a component designed according to the intended product using processes such as CNC machining and is where the molten plastic is injected and cooled. There are several injection molds types. However, based on the temperature held by the runner and the mold,  there are two mold systems: hot runner and cold runner. Each mold system uses a different mechanism which affects plastic fabrication differently. As a result, there is a need for a proper understanding of the hot runner mold vs cold runner mold comparison before selection. This article does the hot runner vs cold runner injection molding comparison by introducing both systems, how they work, and their differences. Furthermore, it shows how to choose the right mold for your project.   What is a Hot Runner Mold?  A hot runner mold is an injection mold with a manifold system (i.e., containing a heating component, manifold, and nozzle) that ensures that molten plastic injected into the mold maintains its temperature. Hot runner injection molding is suitable for molding plastics that require steady flow and injection pressure for part fabrication. Furthermore, with the method, there is a reduction in defects such as sink marks that occur due to fluctuating injection pressure and underfilled molds. Types of Hot Runner Mold Based on the method of maintaining the heat, here are the two types of hot runner molds used in plastic injection molding: Insulated Hot Runners Insulated hot runners molds have extremely thick runners in the mold plate, which causes part of the molten plastic to cool down and insulate the system. The insulation reduces heat loss, allowing the mold system to maintain an open plastic flow. Insulated hot runner molds are less expensive than heated ones because they do not use manifolds and drops. Furthermore, they have flexible gates, reduced defects, and favor easy color change. However, it has a few disadvantages, such as freeze-ups at the gate, non-uniform mold filling, long start-up periods, and the need for a fast cycle to maintain the thermoplastic molten state due to the absence of a manifold system.  Heated hot runners The heated hot runner is the major type of hot runner system with heating achievable using a heating component in one-half of the mold. However, they come in two designs: externally heated and internally heated. Externally heated hot runners: The heating component is outside the mold. As a result, there is no obstruction in the molten thermoplastic flow (better flow control) and no drop in injection pressure. Furthermore, the molten plastic does not freeze and is ideal for color change. Externally heated hot runner molds are suitable for thermosensitive materials. Internally heated hot runners: Here, the heating component is in the mold, leading to a drop in injection pressure, incompatibility with color change, and material hanging up and degrading in the mold. However, there is better flow due to the heated runner and gate tip control. What is a Cold Runner Mold?  A cold runner mold is the basic injection mold with runners at the same temperature as the mold cavity. The system involves injecting the molten plastic into locating ring. Afterward, the molten plastic passes through a sprue and runner, which are cold, before entering the mold cavity. As a result, when the plastic cools, it takes the shape of the mold cavity with the solidified plastic in the runner attached. The cold-runner mold features a large runner (larger than the part), removing the tendency of underfilling the mold. Aside from that, it is suitable for working with any plastic polymer irrespective of heat sensitivity, is less expensive than hot runners, and is easily maintained. However, they generate waste. Types Of Cold Runner Systems There are two types of cold runner molds system based on the number of mold plates: · Two Plate Cold Runner System The two-plate cold runner system comprises two plates with the stationary mold containing the sprue, runners, gate, and cavities. It is the fastest, simplest, and least costly cold runner system. However, the runner is attached to the final product and should be cut off. · Three Plate Cold Runner System A three-plate cold runner system is similar to the two-plate system. However, the three-plate injection mold is flexible with an additional runner plate. Furthermore, there is no need to cut the runner from the injection molded part, and the mold does not require an ejection system for part removal. 3 plate injection mold is friendlier and more flexible. They are the most suitable for working with products with complex designs, and they are a lower-cost alternative to hot runner systems. Disadvantages of this injection mold include long cycle time, complex tool design, and high material waste. Hot Runner Mold vs Cold Runner Mold â Advantages of Each System Each runner mold has its advantages making them suitable for different applications and industries. Here, we will talk about their advantages and how they compare. Hot Runner System Advantages The hot runner system is widely applicable in plastic product fabrication due to the following advantages: Reduced cycle time: One main difference between a hot runner and cold runner injection molding is the cycle time. Hot runner injection molds have a faster cycle time due to the plastic being kept at optimum temperature, increasing flowability. Reduced material wastage: Itâs more cost-effective as the mold system generates little to no material waste.    Optimal Part Quality: Parts made using hot runner molds have better final quality due to the excellent filling profile and injection pressure.  Molding Automation: Automation is possible because there is no need for post-processing processes such as trimming, waste recycling, and removal of runners.  Design Flexibility: There is flexibility in injection mold design in the placement of the gate using the hot tip gate, valve gate, or edge gate. As a result, there is an increase in part aesthetics and optimum filling of mold cavities during the injection. Cold Runner System Advantages The cold runner system has the following advantages: Lower tooling cost: The cold runner mold system has a lower investment cost in injection mold tooling. As a result of the lower tooling cost, molding is cost-effective. Less inspection and maintenance cost: Cold runner molds are not complex. Consequently, there is less need for inspection and maintenance, leading to decreased maintenance costs and downtime. Thermosensitive plastics: Another difference between hot runner and cold runner molds is their application in molding thermosensitive plastics. Cold runner systems are the most suitable for thermally sensitive polymers. Furthermore, they are also suitable for any plastics. Hot Runner Mold vs Cold Runner Mold â Drawbacks of Each System Each runner mold also has its drawbacks. Here, we will talk about their disadvantages and how they compare to each other. Hot Runner System Disadvantages The hot runner system has the following disadvantages: High investment cost: Hot runner systems have a high initial investment and maintenance cost due to the sophistication of the molds and advantages such as reduced cycle time, part quality, and flexibility. High requirement for precision in the equipment: The system requires high-end equipment due to the need for precision. Otherwise, there might be defects because of failure in the machine. An example is the plastic seal failure which can lead to the molten plastic spilling and damaging the hot runner assembly. Cold Runner System Disadvantages Cold runner injection molding has the following disadvantages: Material wastage: Material waste is another difference in the hot runner vs cold runner molding comparison. The molten plastic solidifies in the cold runner system. Consequently, these lead to scraps that need trimming. Injection pressure drop: Heat transfers from the plastic to the mold plates during plastic flow, which causes shrinkage leading to pressure drop and further forming defects such as sink marks and underfilling parts. High cycle time: Cold injection molding has a slower cycle time due to reduced plastic flowability. Aside from that, removing the runner and sprue (especially in the two mold systems) also increases the cycle time.

We have developed hundreds of products and manufactured millions of parts annually for the medical industry. Medical devices include point of care diagnostics, microfluidics, and pharmaceutical drug delivery applications.

In the electronics market we draw upon deep experience in comprehensive analysis and testing for evaluation and verification to design and build lighter, more durable electronics components.

Many mold makers serve your area. We service the New York, New Jersey, Connecticut, Pennsylvania, Florida, California, Illinois, Oregon, Maryland, Massachusetts, Colorado, and Michigan and other regions.

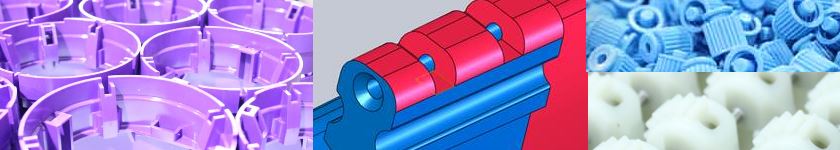

Our precision mold makers injection molding options include scientific molding, R&D molding, high-cavitation molding, micro molding, over molding, and insert molding.

Our mid to high-volume automated and semi-automated manufacturing of plastic injection-molded components and assemblies for single-use, metered-dose, and multi-use disposables for the drug delivery, consumer packaging, and diagnostics industries offer high quality with economic value.

Our mold makers product finishing capabilities include hot stamping, banding, pad printing, silk screening, flaw coating, conductive painting, cosmetic painting, metalizing, and plating.

our product development, including mold makers, is managed by a Project Engineer who monitors and controls deliverables and provides regular status updates.

Being the industry leader of mold makers, Natech’s mold designs are supported by MoldFlow Analysis, a Viscosity Curve, a Cavity Balance Study, a Pressure Window Characterization, a Gate Seal Time Study, and a Cooling Time Study. Natech engineers are masters of insert configuration and design single-cavity R&D molds with steel inserted areas. Interchangeable plates, inserts, and sub-inserts allow for more rapid design iterations at LOWER cost than creating new molds for each feature variation. SPI Class 103 and 104 molds are constructed from P20 steel and aluminum with hot runners and cold runners.

As the industry leader for mold makers, our mold maintenance plan ensures each mold undergoes regular cleaning and review at predefined intervals based upon the number of setups and cycles. Mold inspections, general mold maintenance, major mold maintenance, and preventative maintenance are standard operating procedures.

Hot Runner Temperature Controller also called HRTC in short form. Hot runner temperature controller is used to run mainly Plastic Injection Molding Machine's molds. Let's try to understand 2 main types of molds. Hot Runner vs Cold Runner Injection Mold: Key Differences You Need to Know   Home Blog Hot Runner vs Cold Runner Injection Mold: Key Differences You Need to Know Hot Runner vs Cold Runner Injection Mold: Key Differences You Need to Know Updated: October 17, 2022 An injection mold is a component designed according to the intended product using processes such as CNC machining and is where the molten plastic is injected and cooled. There are several injection molds types. However, based on the temperature held by the runner and the mold,  there are two mold systems: hot runner and cold runner. Each mold system uses a different mechanism which affects plastic fabrication differently. As a result, there is a need for a proper understanding of the hot runner mold vs cold runner mold comparison before selection. This article does the hot runner vs cold runner injection molding comparison by introducing both systems, how they work, and their differences. Furthermore, it shows how to choose the right mold for your project.   What is a Hot Runner Mold?  A hot runner mold is an injection mold with a manifold system (i.e., containing a heating component, manifold, and nozzle) that ensures that molten plastic injected into the mold maintains its temperature. Hot runner injection molding is suitable for molding plastics that require steady flow and injection pressure for part fabrication. Furthermore, with the method, there is a reduction in defects such as sink marks that occur due to fluctuating injection pressure and underfilled molds. Types of Hot Runner Mold Based on the method of maintaining the heat, here are the two types of hot runner molds used in plastic injection molding: Insulated Hot Runners Insulated hot runners molds have extremely thick runners in the mold plate, which causes part of the molten plastic to cool down and insulate the system. The insulation reduces heat loss, allowing the mold system to maintain an open plastic flow. Insulated hot runner molds are less expensive than heated ones because they do not use manifolds and drops. Furthermore, they have flexible gates, reduced defects, and favor easy color change. However, it has a few disadvantages, such as freeze-ups at the gate, non-uniform mold filling, long start-up periods, and the need for a fast cycle to maintain the thermoplastic molten state due to the absence of a manifold system.  Heated hot runners The heated hot runner is the major type of hot runner system with heating achievable using a heating component in one-half of the mold. However, they come in two designs: externally heated and internally heated. Externally heated hot runners: The heating component is outside the mold. As a result, there is no obstruction in the molten thermoplastic flow (better flow control) and no drop in injection pressure. Furthermore, the molten plastic does not freeze and is ideal for color change. Externally heated hot runner molds are suitable for thermosensitive materials. Internally heated hot runners: Here, the heating component is in the mold, leading to a drop in injection pressure, incompatibility with color change, and material hanging up and degrading in the mold. However, there is better flow due to the heated runner and gate tip control. What is a Cold Runner Mold?  A cold runner mold is the basic injection mold with runners at the same temperature as the mold cavity. The system involves injecting the molten plastic into locating ring. Afterward, the molten plastic passes through a sprue and runner, which are cold, before entering the mold cavity. As a result, when the plastic cools, it takes the shape of the mold cavity with the solidified plastic in the runner attached. The cold-runner mold features a large runner (larger than the part), removing the tendency of underfilling the mold. Aside from that, it is suitable for working with any plastic polymer irrespective of heat sensitivity, is less expensive than hot runners, and is easily maintained. However, they generate waste. Types Of Cold Runner Systems There are two types of cold runner molds system based on the number of mold plates: · Two Plate Cold Runner System The two-plate cold runner system comprises two plates with the stationary mold containing the sprue, runners, gate, and cavities. It is the fastest, simplest, and least costly cold runner system. However, the runner is attached to the final product and should be cut off. · Three Plate Cold Runner System A three-plate cold runner system is similar to the two-plate system. However, the three-plate injection mold is flexible with an additional runner plate. Furthermore, there is no need to cut the runner from the injection molded part, and the mold does not require an ejection system for part removal. 3 plate injection mold is friendlier and more flexible. They are the most suitable for working with products with complex designs, and they are a lower-cost alternative to hot runner systems. Disadvantages of this injection mold include long cycle time, complex tool design, and high material waste. Hot Runner Mold vs Cold Runner Mold â Advantages of Each System Each runner mold has its advantages making them suitable for different applications and industries. Here, we will talk about their advantages and how they compare. Hot Runner System Advantages The hot runner system is widely applicable in plastic product fabrication due to the following advantages: Reduced cycle time: One main difference between a hot runner and cold runner injection molding is the cycle time. Hot runner injection molds have a faster cycle time due to the plastic being kept at optimum temperature, increasing flowability. Reduced material wastage: Itâs more cost-effective as the mold system generates little to no material waste.    Optimal Part Quality: Parts made using hot runner molds have better final quality due to the excellent filling profile and injection pressure.  Molding Automation: Automation is possible because there is no need for post-processing processes such as trimming, waste recycling, and removal of runners.  Design Flexibility: There is flexibility in injection mold design in the placement of the gate using the hot tip gate, valve gate, or edge gate. As a result, there is an increase in part aesthetics and optimum filling of mold cavities during the injection. Cold Runner System Advantages The cold runner system has the following advantages: Lower tooling cost: The cold runner mold system has a lower investment cost in injection mold tooling. As a result of the lower tooling cost, molding is cost-effective. Less inspection and maintenance cost: Cold runner molds are not complex. Consequently, there is less need for inspection and maintenance, leading to decreased maintenance costs and downtime. Thermosensitive plastics: Another difference between hot runner and cold runner molds is their application in molding thermosensitive plastics. Cold runner systems are the most suitable for thermally sensitive polymers. Furthermore, they are also suitable for any plastics. Hot Runner Mold vs Cold Runner Mold â Drawbacks of Each System Each runner mold also has its drawbacks. Here, we will talk about their disadvantages and how they compare to each other. Hot Runner System Disadvantages The hot runner system has the following disadvantages: High investment cost: Hot runner systems have a high initial investment and maintenance cost due to the sophistication of the molds and advantages such as reduced cycle time, part quality, and flexibility. High requirement for precision in the equipment: The system requires high-end equipment due to the need for precision. Otherwise, there might be defects because of failure in the machine. An example is the plastic seal failure which can lead to the molten plastic spilling and damaging the hot runner assembly. Cold Runner System Disadvantages Cold runner injection molding has the following disadvantages: Material wastage: Material waste is another difference in the hot runner vs cold runner molding comparison. The molten plastic solidifies in the cold runner system. Consequently, these lead to scraps that need trimming. Injection pressure drop: Heat transfers from the plastic to the mold plates during plastic flow, which causes shrinkage leading to pressure drop and further forming defects such as sink marks and underfilling parts. High cycle time: Cold injection molding has a slower cycle time due to reduced plastic flowability. Aside from that, removing the runner and sprue (especially in the two mold systems) also increases the cycle time.

Clients trust Natech to be the leader of mold makers because of our experts in engineering and manufacturing. Our mold makers engineers ‘ experience includes mold qualifications in medical IQ/OQ/PQ, high volume automation in consumer packaging, and engineering-grade resins and ultra-polymers in electronics.

For the consumer market we specialize in the automated production of high-volume disposables, unit-dose packaging, caps and closures, and over-the counter diagnostics and drug delivery applications.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly