UK administrations update: July 2 – 9 - plastic moulding business for sale

Author:gly Date: 2024-09-30

The presentation covered the broad technologies of Material Extrusion (MEX)-based processes, where the material is selectively dispensed through a nozzle or orifice. The material being extruded can become the final part itself, as in the case of pure polymer extrusion or hot extruding a metallic wire or polymer loaded with metal powder to form the final part.

Prof Apelian acknowledged that talent is a scarce commodity and he quoted Klaus Schwab from the World Economic Forum, who stated that, “in the 4th Industrial Revolution, it is all about talentism; not capitalism nor socialism.” Development and utilisation of the talent pool will be the key to the success of the 4th Industrial Revolution. An illustration of the dream of Industry 4.2TM and the future of work and the worker is shown in Fig. 6.

It was concluded that ABS and HIPS e-waste can be recycled in up to six cycles with no significant loss of mechanical, thermal or flow properties. There was no significant change in the technical aspects of ABS and HIPS e-waste over six reprocessing cycles, as observed in thermogravimetric analyses.

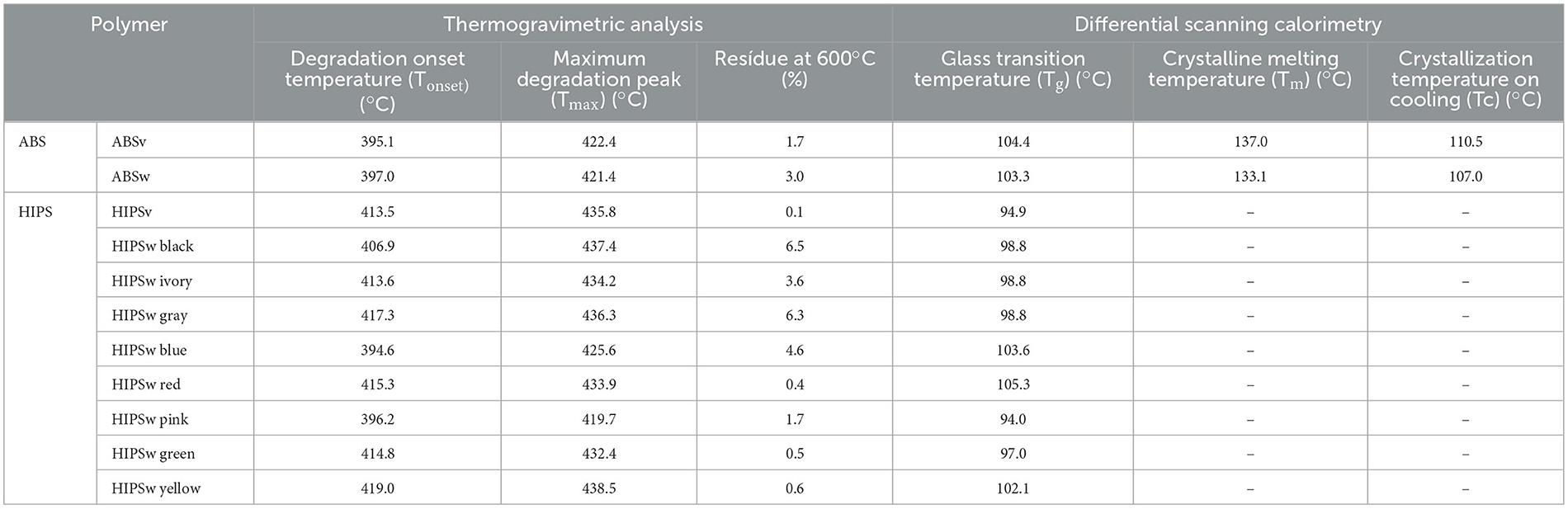

DSC analyses were performed primarily to determine the glass transition temperature (Tg) of the virgin and post-consumer ABS and HIPS (Table 3). This property identifies the temperature at which the polymeric material changes from a glassy to a rubbery state. The mobility of molecular chains increases from Tg and the polymers become more elastic and flexible (Gregorova, 2013).

Bai, X., Isaac, D. H., and Smith, K. (2007). Reprocessing acrylonitrile-butadiene-styrene plastics: structure-property relationships. Polym. Eng. Sci. 47, 120–130. doi: 10.1002/pen.20681

Discover suppliers of these and more in our advertisers’ index and buyer’s guide, available in the back of PIM International.

For ABSv, elastic modulus and maximum flexural stress were almost unchanged across the six reprocessing cycles at around 2,500 and 70 MPa, respectively, as shown in Table 8. However, for ABSv, maximum flexural stress declined by approximately 6% from the third reprocessing cycle onwards, indicating that less force was needed from this point for deformation to occur under flexion.

Figure 5. Test specimens for tensile testing obtained by injection of ABS and HIPS, virgin and from e-waste, reprocessed six times.

Table 9 shows the impact strength of reprocessed virgin and HIPS e-waste. The impact strength of HIPSv remains almost the same (61 J/m) until cycle five and then declines by around 4% to approximately 58 J/m in cycle six. HIPSw exhibited impact strength of 35 J/m until the fourth reprocessing cycle, followed by a 16% reduction to about 29 J/m from cycle four to six. While both ABS and HIPS contain rubber, HIPS e-waste likely has a smaller rubber phase than its virgin counterpart, as confirmed by FTIR, in which the height of peaks corresponding to the butadiene group declined from the fifth reprocessing cycle onwards, suggesting lower impact strength. In the present study, recycled HIPS did not exhibit the degradation reported in the literature (Hirayama and Saron, 2015), indicating that the remolding conditions used were ideal for maintaining the properties of the polymer.

Brennan, L. B., Isaac, D. H., and Arnold, J. C. (2002). Recycling of acrylonitrile-butadiene-styrene and high-impact polystyrene from waste computer equipment. J. Appl. Polym. Sci. 86, 572–578. doi: 10.1002/app.10833

Although MIM2023 was organised as a hybrid event, including both online and in-person presentations, the in-person presentations significantly outnumbered the virtual ones. This was an extremely good sign for the industry, which is rebounding back to its pre-COVID days with attendance at the conference climbing to 138 and participation from 11 countries. International participation was still slightly weaker than expected, but is anticipated to bounce back next year.

All authors contributed equally to data collection and writing the manuscript. All authors contributed to the article and approved the submitted version.

In the light of the above, this study aimed to investigate the mechanical reprocessing of ABS and HIPS from e-waste compared with the processing of virgin material to assess the possibility of their reintroduction or not to the same production cycle.

One sinter-based AM process that has the potential to compete with MIM is Incus’s process based on Vat Photopolymerisation. A presentation of this process was given by Dr György Harakály of Incus, Austria, entitled Lithography-based Metal Manufacturing. His paper outlined the advantages of this process including the ability to produce complex green parts in a small- to medium-size range (1–200 g component mass), the highest resolution and surface aesthetics of metal AM processes, a wide range of materials with the possibility of processing non-flowable and non-weldable materials, a simple production process with easy preparation of printing jobs and quick exchange of materials, and safe working environment with no metal dust or high-power laser.

Wäger, P. A., and Hischier, R. (2015). Life cycle assessment of post-consumer plastics production from waste electrical and electronic equipment (WEEE) treatment residues in a Central European plastics recycling plant. Sci. Tot. Environ. 529, 158–167. doi: 10.1016/j.scitotenv.2015.05.043

Hirayama, D., and Saron, C. (2018). Morphologic and mechanical properties of blends from recycled acrylonitrile-butadiene-styrene and high-impact polystyrene. Polymer 135, 271–278. doi: 10.1016/j.polymer.2017.12.038

Extensive MIM, CIM industry and sinter-based AM industry news, plus the following exclusive deep-dive articles and reports:

Contrastingly, a MIM-type of feedstock, where metal powder is mixed with organic binders to form a feedstock, is extruded through a nozzle to build a geometric shape that is subsequently subjected to debinding and a consolidation step to result in the final part. This multi-step process has similarities with the MIM process, except for the geometric shaping, which is accomplished by a build process, or printing, instead of moulding.

A major part of the presentation was based on Binder Jetting (BJT) technology, which has gained the best traction among all the sinter-based AM processes thanks to its promise of high-volume production capability at a low cost. The presentation pointed out that some of the technologies are complementary to MIM, supporting MIM companies in terms of quick tooling and even rapid prototyping of actual metal parts. However, it was pointed out that some processes, such as BJT, can also pose competition to MIM due to their ability to fabricate parts with high productivity and without the requirement of any tooling.

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Thanh Truc, N. T., and Lee, B. K. (2017). Selective separation of ABS/PC containing BFRs from ABSs mixture of WEEE by developing hydrophilicity with ZnO coating under microwave treatment. J. Hazard. Mater. 329, 84–91. doi: 10.1016/j.jhazmat.2017.01.027

The Tonset and Tmax values for ABSv and ABSw were 395 and 422°C and 397 and 421°C, respectively. All the degradation curves for HIPSw were similar, varying between 419.7 and 438.5°C, with 0.5–6.5% undegraded waste. It is important to underscore that, in addition to pigments, inert fillers are used in polymers to lower the cost of the final product and generally remain as residue in thermal degradation (Arráez et al., 2019).

Similar behavior was observed for ABSw, with a small variation (approximately 4%) across the six cycles. However, there was a 15% increase from the first to sixth extrusion cycle and approximately 10% for extrusion + injection (Table 6). Analysis of the standard deviations (0.2 g/10 min) after each cycle for extrusion and extrusion + injection also showed no variations, demonstrating that despite undergoing two types of processing, the MFI of ABSw shows that processing has little effect on the melt flow index ty of the material.

The variation in the mass of the polymeric materials was analyzed by TGA (TA Instruments, Q500), using a temperature ramp of 10°C/min from 25 to 600 °C under a nitrogen atmosphere, with a flow rate of 20 mL/min. The samples weighed around 17 mg and were placed in an open ceramic container. Mass loss vs. temperature curves and their derivatives were analyzed by differential thermogravimetry (DTG).

The results of this study were obtained as part of the Master's degree of FT, who received a grant from Coordination for the Improvement of Higher Education Personnel (CAPES).

Ragaert, K., Delva, L., and Van Geem, K. (2017). Mechanical and chemical recycling of solid plastic waste. Waste Manag. 69, 24–58. doi: 10.1016/j.wasman.2017.07.044

Both the virgin and e-waste polymers were extruded six times, that is, submitted to six reprocessing cycles. It is important to note that the HIPS waste samples, that is, all the different colored flakes, were extruded together to comply with the minimum amount needed for processing 6 times. The extruder used (Teck Tril DCT-20) has a production capacity of 10–20 kg/h and nine temperature zones, and the testing conditions were established based on recommendations in the technical specifications for the respective virgin polymers (Formosa Chemicals and Fibre Corporation, 2021; Innova, 2021), as shown in Table 2. The material was extruded in a continuous cylindrical filament, cooled in water at ambient temperature and then granulated. Approximately 1.0 kg of pellets were obtained per cycle for subsequent assessment of the properties of the reprocessed materials.

HIPS was supplied already ground into different-colored flakes, with sizes ranging from 2 mm to larger than 5 mm. The flakes were manually separated by color into a 100 g sample to confirm that they were in fact HIPS and the percentage mass of each color was calculated. Each color was denominated as a subsample.

Don't miss any new issue of PIM International, and stay up to date with the latest industry news. Sign up to our fortnightly newsletter.

TGA curves and derivatives for virgin ABS and ABS e-waste reprocessed up to 6 times showed a well-defined decomposition stage. The results obtained for the initial decomposition temperatures (Tonset) of virgin ABS and WEEE reprocessed up to 6 times showed very similar decomposition temperatures, with 378 to 384°C for reprocessed ABSv and 381 to 386° for reprocessed ABSw. The Tonset values for ABSv were ABSv0 = 382°C; ABSv1 = 382°C; ABSv2 = 379°C; ABSv3 = 381°C; ABSv4 = 381°C; ABSv5 = 378°C; ABSv6 = 384°C, and for ABSw: ABSw0 = 384°C; ABSw1 = 386°C; ABSw2 = 382°C; ABSw3 = 382°C; ABSw4 = 381°C; ABSw5 = 381°C; and ABSw6 = 382°C.

Pérez, J. M., Vilas, J. L., Laza, J. M., Arnáiz, S., Mijangos, F., Bilbao, E., et al. (2010). Effect of reprocessing and accelerated weathering on ABS properties. J. Polym. Environ. 18, 71–78. doi: 10.1007/s10924-009-0154-7

The ABS from tablet casings was ground in a knife mill equipped with an approximately 9.0 mm mesh sieve, resulting in plastic pieces smaller than 2.0 mm, denominated ground flakes. All the ABS flakes were black.

Saron, C., and Felisberti, M. I. (2006). Ação de colorantes na degradação e estabilização de polímeros. Quim. Nova 29, 124–128. doi: 10.1590/S0100-40422006000100022

Fig. 11 shows the AM button body and the button cap in both the as-sintered and machined conditions. The rapid prototyping using the BJT process was the key to the success of the project. Once the design and properties were achieved (that satisfied the customer), attention was focused on MIM for high-volume production of the actual components.

FTIR was used to identify and characterize the functional groups present in the virgin and e-waste polymers. Table 4 presents the main FTIR transmittance bands in the ABSv and HIPSv copolymers. There was considerable similarity between the transmittance peaks of the two virgin polymers and the out-of-plane deformation bands at 3,025 cm−1 corresponding to C-H; the peaks at 1,600, 1,490, 700, and 760 cm−1 are attributed to C=C of the polystyrene ring and those at 966 and 911 cm−1 to aliphatic C=C, but more specifically to trans-1.4 and vinyl-1.2 corresponding to the polybutadiene phase. In addition to these bands, medium-intensity peaks were observed at 2,237 cm−1 only in the virgin ABS spectrum, corresponding to the nitrile group of the acrylonitrile. This peak is not present in HIPS. Similar results were reported for ABS in research by Kamelian et al. (2014).

Fourier-transform infrared spectroscopy (FTIR) (Varian 3100 FT-IR Excalibur Series) was used to identify the functional groups in the polymers. Spectra were obtained using an attentuated total reflectance (ATR) accessory within a wavelength range of 4,000 to 600 cm−1.

Klein (2009) studied the effect of thermomechanical and photooxidative degradation of ABS and found that the reduction of C=C bonds in the elastomeric phase suggests possible degradation of the polymer, whose bands related to out-of-plane angular vibration are more sensitive than in-plane angular absorption of C=C bonds. Other authors (Luna et al., 2019) also reported that rubber degradation is associated with molecular scission, which results in smaller chains and a larger number of chain terminals and/or cross-linking, forming a highly bonded network.

Luna, C. B. B., Gomes, F. B. C., Siqueira, D. D., and Araújo, E. M. (2019). Influence of thermo-oxidative aging on the mechanical and yellowing properties of polystyrene blends with recycled styrene-butadiene rubber (SBR). Rev. Mater. 24, 1–13. doi: 10.1590/s1517-707620190003.0729

Flexural strength was analyzed for virgin and ABS and HIPS e-waste polymers submitted to six reprocessing cycles yielding the following data: flexural strength, elastic modulus and maximum flexural stress. Maximum flexural stress is the stress applied to the center of the test specimen needed to deform it.

No yellowing was observed in the reprocessed ABSw and HIPSw samples (Figure 5) since both of these polymers were black. Reprocessed HIPSw remained an opaque black through all six extrusions, becoming slightly brighter after injection of the pellets, whereas ABS waste pellets were considerably brighter than the original material from the second cycle onwards. This greater bightness was also observed in the virgin ABS pellet, which naturally exhibited this characteristic before processing.

Beigbeder, J., Perrin, D., Mascaro, J. F., and Lopez-Cuesta, J. M. (2013). Study of the physico-chemical properties of recycled polymers from waste electrical and electronic equipment (WEEE) sorted by high resolution near infrared devices. Resour. Conserv. Recycl. 78, 105–114. doi: 10.1016/j.resconrec.2013.07.006

Maximum degradation temperatures (Tmax) for reprocessed ABSv and ABSw ranged from 402 to 410°C and 410 to 416°C, respectively, with the following values obtained for ABSv: ABSv0 = 409°C; ABSv1 = 409°C; ABSv2 = 407°C; ABSv3 = 408°C; ABSv4 = 408°C; ABSv5 = 402°C; and ABSv6 = 410°C, and for ABSw: ABSw0 = 415°C; ABSw1 = 417°C; ABSw2 = 412°C; ABSw3 = 412°C; ABSw4 = 411°C; ABSw5 = 411°C; and ABSw6 = 413°C.

*Correspondence: Flávia da Silva Müller Teixeira, flavia.smt@ima.ufrj.br; Elen Beatriz Acordi Vasques Pacheco, elen@ima.ufrj.br

The mechanical properties assessed in the reprocessed virgin and ABS and HIPS e-waste polymers were tensile, flexural, and impact strength.

In general, reprocessing leads to polymer degradation and, consequently, loss of properties (Ha and Kim, 2012; Scaffaro et al., 2012). Brennan et al. (2002), Bai et al. (2007), Karahaliou and Tarantili (2009), Beigbeder et al. (2013), and Hirayama and Saron (2015, 2018) confirmed that degradation occurred during ABS recycling due to a deterioration in properties. The same occurred with HIPS (Hirayama and Saron, 2015, 2018).

Gregorova, A. (2013). “Application of Differential Scanning Calorimetry to the characterization of biopolymers,” in Application of Calorimetry in a Wide Context - Applications of Calorimetry in a Wide Context - 4 Differential Scanning Calorimetry, Isothermal Titration Calorimetry and Microcalorimetry, Chapter 1, ed A. A. Elkordy (IntechOpen), 3–20. doi: 10.5772/53822

Comparison of MFI values for HIPSw extrusion + injection with those for extrusion revealed increases of 19, 13, 10, and 14% for the first, fourth, fifth and sixth cycles, respectively.

For ABSv and ABSw, the yield point occurs at around 43 MPa, when strain is approximately 3%. The values obtained for the reprocessed materials were practically the same, indicating that the tensile properties of both polymers were almost unchanged after the six processing cycles. These findings corroborate those reported in the literature (Bai et al., 2007; Karahaliou and Tarantili, 2009; Beigbeder et al., 2013).

Rahimi, M., Esfahanian, M., and Moradi, M. (2014). Effect of reprocessing on shrinkage and mechanical properties of ABS and investigating the proper blend of virgin and recycled ABS in injection molding. J. Mater. Process. Technol. 214, 2359–2365. doi: 10.1016/j.jmatprotec.2014.04.028

Waheed, S., Cabot, J. M., Smejkal, P., Farajikhah, S., Sayyar, S., Innis, P. C., et al. (2019). Three-dimensional printing of abrasive, hard, and thermally conductive synthetic microdiamond-polymer composite using low-cost fused deposition modeling printer. ACS Appl. Mater. Interfaces 11, 4353–4363. doi: 10.1021/acsami.8b18232

Silva, C. E., Silva, L. P., Edwards, H. G. M., and De Oliveira, L. F. C. (2006). Diffuse reflection FTIR spectral database of dyes and pigments. Anal. Bioanal. Chem. 386, 2183–2191. doi: 10.1007/s00216-006-0865-8

Comparison between the first and sixth cycles for virgin HIPS and HIPS e-waste (Figure 6H) demonstrates that the virgin polymer tends to degrade more with reprocessing in the region of the butadiene group. This result can be analyzed in conjunction the MFI findings for HIPSv, whereby there was a greater increase in MFI in the first cycle, which may be a characteristic of decreased molar mass due to degradation.

TGA curves and derivatives for HIPSv and HIPSw reprocessed up to 6 times also indicated a decomposition stage. The Tonset of reprocessed HIPSv and HIPSw was 401–402°C and 395–396°C in all cycles, respectively. The maximum degradation temperatures for both HIPSv and HIPSw were 424°C-425°C. The mass percentage of residue at 600°C for HIPSv was 0.1–0.3% and around 1–3% for HIPSw. These findings indicate that both the virgin and WEEE polymeric materials showed good thermal stability, which remained practically unchanged even after six processing cycles.

Since the very first PM Titanium conference in Brisbane, Australia, in 2011, the PMTi series has been the essential meeting point where technical a...»

Virgin ABS and HIPS exhibited greater stability than their e-waste counterparts; however, it is important to underscore that WEEE polymers have previously undergone molding and maintain their good properties across six reprocessing cycles after becoming waste, as observed in this study.

Initially, the WEEE samples were visually characterized. The ABS tablet casings were black and subsequently ground (Figure 1). A total of eight colors were identified for HIPS e-waste (black, ivory, gray, blue, red, pink, green, and yellow), which was manually sorted by color, as shown in Figure 1. All the characterization and processing equipment is located at the Instituto de Macromoleculas Professora Eloisa Mano at the Federal University of Rio de Janeiro, Brazil.

ASTM International (2017). D790-17. Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials.

The FTIR results for ABSv, ABSw, HIPSv, and HIPS no reprocessed and reprocessed six times are shown in Figures 6A, B, respectively. The FTIR results for ABSv reprocessed six times (Figure 6A) demonstrated that the main bands corresponding to the virgin polymer remained unchanged, that is, there was no decline and no new bands emerged with successive cycles. Peaks corresponding to nitrile (Figure 6C) and butadiene (Figure 6D) in the FTIR curves for ABS e-waste are slightly smaller than those of ABSw0 and more distinct for ABSw6. Figures 6C, D show the height of the peaks, with the most distinct regions of the nitrile group (2,237 cm−1) and trans-1.4 and vinyl-1.2 corresponding to the polybutadiene phase (966 and 911 cm−1).

An interesting area of process innovation is gigacasting in the automotive industry, leading to a simplification of vehicle structures. This innovation has the potential to reduce the number of automotive parts needed for a car body structure from 171 to two, and require 1600 fewer welds. To keep up with the demand for large casting sizes, the die cast machine size range has increased dramatically over time. Prof Apelian pointed out that LK, the global leader in hot chamber and cold chamber die casting machines, has increased the locking force of its hot chamber die cast machine cells from 2000 to 12,000 tonnes since 1970 (Fig. 5).

Santana and Manrich (2002) studied HIPS submitted to up to five reprocessing cycles and recorded a 12% rise in MFI in the first cycle, while the index remained constant at up to 3% after 5 cycles. According to the authors, this increase was the result of consecutive grinding and injection molding.

The virgin HIPS pellets became yellower as the number of reprocessing cycles increased, particularly from the second cycle onwards (Figure 5). The color change may be a sign of polymer degradation (Luna et al., 2019).

This is a story from what once looked like the edge of the metal Additive Manufacturing universe. A decade ago, the idea of a Metal Injection Moldi...»

Another interesting presentation from Uniformity Labs (UL), California, USA, was given by Dr Joseph Schramm, entitled ‘Performance of Highly Uniform High Density Multimodal Stainless Steel Powders in Metal Injection Molding.’ This presentation highlighted the benefits of designed multimodal powders to attain higher solids loading in MIM feedstocks. The presentation highlighted the ability of UL powders to attain high relative densities, approaching that of the densest crystalline particle packings, while retaining their ability to flow without phase separation. Fig. 12 shows a schematic of the densest natural crystalline packing of binary spheres and the UL maximally random jammed packing, both using a powder size ratio of 5:1. It can be seen that the UL powder can attain a packing density that is almost the same as the densest natural crystalline packing.

Wang, R., and Xu, Z. (2014). Recycling of non-metallic fractions from waste electrical and electronic equipment (WEEE): a review. Waste Manag. 34, 1455–1469. doi: 10.1016/j.wasman.2014.03.004

Table 9 shows the impact strength of reprocessed virgin and ABS e-waste. The impact strength of virgin ABS remained practically unchanged across all six cycles at approximately 115 J/m. For ABSw, there was a decline of around 14% by the second cycle, but the property remained almost the same from the third to sixth cycle considering the standard deviations. ABS and ABSv e-waste are polymers of different grades and have distinct characteristics, with the former exhibiting lower impact strength than the latter, making it more brittle. In other words, its ability to absorb energy under the load of the pendulum is lower than that of the virgin material, a finding also corroborated by tensile testing, whereby ABSw showed less elongation at break, indicating that it is less ductile.

Teixeira, F. S. M., Peres, A. C. C., Gomes, T. S., Visconte, L. L. Y., and Pacheco, E. B. A. V. (2021). A review on the applicability of life cycle assessment to evaluate the technical and environmental properties of waste electrical and electronic equipment. J. Polym. Environ. 29, 1333–1349. doi: 10.1007/s10924-020-01966-7

The MFI of HIPS was 5.3 g/10 min, while the value recorded for HIPS e-waste, in which all the HIPS samples were combined, was 6.5 g/10 min (Figure 4). In general, the MFI of the HIPS e-waste samples showed greater homogeneity, despite their different origins. The different HIPS grades used in EEE include HIPS825 (MFI = 5.5), HIPS RC600 (MFI = 6.0), and HIPS RT441M (MFI = 6.5; Innova, 2021).

Small MFI variations were observed for HIPSw, namely a 4% increase from the first to the second extrusion, 5% from the fifth to the sixth and 12% from the first to the sixth, and 6% for extrusion +injection (Table 6). An increase in MFI was also reported in other studies.

Table 3 presents the TGA and DSC results for virgin and e-waste ABS and HIPS: the degradation onset temperature (Tonset), maximum degradation temperature (Tmax), and percentage of undegraded waste at 600°C obtained from the thermograms; and glass transition Temperature (Tg).

Blue HIPSw displayed peaks at 3,695 and 3,618 cm−1 corresponding to O-H stretching and at 1,435 and 874 cm−1 attributed to carbonate stretching. In addition to these bands, Silva et al. (2006) reported that bands at 1,106, 1,029, 1,010, and 913 cm−1 are characteristic of a blue pigment called azurite, whose molecular formula is Cu3(CO3)2(OH)2. For the black, ivory and red HIPSw samples, a transmittance peak was observed at 2,237 cm−1, corresponding to the nitrile group. However, unlike ABSv and ABSw, the intensity of the peaks on the HIPS e-waste curves is low and may be associated with the presence of dyes, pigments or ABS. The possible presence of nitrile could be from a HIPS/ABS blend, but this percentage could not be quantified. It is important to note that the HIPS was waste provided by a recycler that does not use techniques to identify the materials processed.

Ramesh, V., Biswal, M., Mohanty, S., and Nayak, S. K. (2014). Recycling of engineering plastics from waste electrical and electronic equipments: influence of virgin polycarbonate and impact modifier on the final performance of blends. Waste Manag. Res. 32, 379–388. doi: 10.1177/0734242X14528404

I would like to acknowledge the support received from MPIF staff (James Adams and Bill Edwards) and the authors for their help with the figures used in this report.

Klein, F. R. (2009). Estudo da degradação térmomecânica e fotooxidativa de poli(acrilonitrila-butadieno-estireno) para fins de reciclagem primária. Florianópolis: Dissertação de Mestrado do Programa de Pós-Graduação em Ciência e Engenharia de Materiais da Universidade Federal de Santa Catarina

After reprocessing, the virgin and e-waste materials were analyzed by FTIR, TGA, DSC, and MFI following the same procedures used for the original raw materials. The mechanical properties (tensile, flexural, and impact strength) of the reprocessed materials were also evaluated, using injected test specimens of material.

As expected, differences were observed in the thermal stability of virgin and post-consumer polymers. The variation in degradation temperatures for the different colored HIPSw was also expected. For HIPSw of the same grade, the different pigments or dyes interact differently with the polymer matrix, increasing or hampering their degradation under heating. According to Saron and Felisberti (2006), pigments and dyes have different chemical structures and interaction between them and the polymer alters its stability, potentially affecting its useful life and performance and even improving its thermal stability.

Plastic waste is considered a resource capable of replacing virgin materials (Huysveld et al., 2019), given the minimum technical requirements for the same application; or to be used in the manufacture of a product with properties that differ from those of the original material. Both cases involve minimal use of new resources (Xavier et al., 2021).

Menikpura, S. N. M., Santo, A., and Hotta, Y. (2014). Assessing the climate co-benefits from Waste Electrical and Electronic Equipment (WEEE) recycling in Japan. J. Clean. Prod. 74, 183–190. doi: 10.1016/j.jclepro.2014.03.040

Rahimi et al. (2014) observed a 24% decrease in impact strength from the first to the fifth reprocessing cycle in ABS. Salari and Ranjbar (2008), also studied the impact strength of ABS reprocessed five times and found a 14% decrease in the first cycle, which they attributed to its smaller molar mass, lower entanglement density of the SAN matrix and polybutadiene degradation. Rahimi et al. (2014), reported that some additives used in ABS production improve its impact strength, so that their reduced efficacy during reprocessing may be another effect of this process.

Differences in the onset and maximum degradation temperatures of ABSv and ABSw were very small. The value obtained for ABSw was 3.0%, higher than that of the virgin material but different from that of the virgin material with no pigment (ABSv), which was black.

Karunadasa, K. S. P., Manoratne, C. H., Pitawala, H. M. T. G. A., and Rajapakse, R. M. G. (2019). Thermal decomposition of calcium carbonate (calcite polymorph) as examined by in-situ high-temperature X-ray powder diffraction. J. Phys. Chem. Solids 134, 21–28. doi: 10.1016/j.jpcs.2019.05.023

Citation: Teixeira FdSM, Peres ACdC and Pacheco EBAV (2023) Mechanical recycling of acrylonitrile-butadiene-styrene copolymer and high impact polystyrene from waste electrical and electronic equipment to comply with the circular economy. Front. Sustain. 4:1203457. doi: 10.3389/frsus.2023.1203457

The stress vs. strain curves for virgin ABS and HIPS and reprocessed WEEE were typical of plastics and similar in shape. Both ABS and HIPS show linear behavior at the beginning of the curve, where there is a modulus of elasticity or Young's modulus (ε). As the polymer begins to experience strain, it transitions from elastic to plastic deformation at a point of maximum stress known as the yield point (θr), where yield point elongation (εr) can also be obtained. Strain continues until rupture (θy), when the curve slopes downward and elongation at break (εy) can be obtained. Table 7 presents the results for Young's modulus, stress and strain at Yield and break of virgin and ABS e-waste and virgin and HIPS e-waste.

Salari, D., and Ranjbar, H. (2008). Study on the recycling of ABS resins: simulation of reprocessing and thermo-oxidation. Iran. Polym. J. 17, 599–610.

Recycling is an excellent option for a more environmentally correct destination for post-consumer plastics (Ragaert et al., 2017) and those from EEE. Recovering these plastics is vital and urgent from a human health, environmental, social and economic perspective considering, for example, saving space in landfills and energy in the extraction and processing of virgin materials, transport, expansion of social programs with digital inclusion and job creation in the supply chain of maintenance, and recycling activities (Rodrigues, 2007; Menikpura et al., 2014; Campolina et al., 2017; Teixeira et al., 2021).

Introduction: Acrylonitrile-butadiene-styrene copolymer (ABS) and high impact polystyrene (HIPS) are plastics typically found in waste electrical and electronic equipment (WEEE or e-waste). As such, recycling is a beneficial method for reintroducing polymeric materials from electrical and electronic equipment to the same production cycle. This study aimed to investigate mechanical recycling of ABS and HIPS from WEEE reprocessed six times, totaling 24 cycles.

The current scenario, where AM can be complementary to MIM, was very well covered in the presentation by Gaetano Mariella of PTI Tech Inc., New Jersey, USA. In his presentation entitled ‘Utilizing Metal Injection Molding and AM Binder Jetting in the Production of a 316L Industrial Part’, Gaetano detailed a case study that was initiated due to COVID-19. PTI was approached by a major elevator company to solve a problem with their current elevator button panels.

Results: Average energy consumption per extrusion and injection cycle was 0.7 and 2.0 kW/kg, respectively. There was a 30% increase in MFI from the first to sixth reprocessing cycle for virgin HIPS (5.5 g/10 min in 200°C and 5 kg), the largest among the polymers. The values for virgin ABS (6.0 g/10 min in 200°C and 5 kg) and ABS and HIPS from WEE increased by 11–15% from the first to sixth cycle. Impact strength was affected from the second reprocessing cycle onwards for ABS e-waste (14% decrease) and in the fifth cycle (16% decrease) for HIPS e-waste.

Strain at the yield point is similar for HIPSv and HIPSw (Table 7) after each reprocessing cycle, at around 2%. Additionally, Young's modulus, the yield point and elongation at break remained almost unchanged across the HIPS reprocessing cycles. However, HIPSw differed from HIPSv in terms of the elastic modulus, rupture point and elongation at break, corroborating the different grades of the two materials. HIPSw obtained a Young's modulus greater than 2,000 MPa, rupture point of approximately 29 MPa and 13% elongation at break, likely due to the presence of fillers, indicating that this material is harder and not as tough.

Vilaplana, F., Ribes-Greus, A., and Karlsson, S. (2007). Analytical strategies for the quality assessment of recycled high-impact polystyrene: a combination of thermal analysis, vibrational spectroscopy, and chromatography. Anal. Chim. Acta 604, 18–28. doi: 10.1016/j.aca.2007.04.046

With respect to the environmental aspect, energy consumption in the first extrusion cycle for HIPSw was 12% greater than that of the other five cycles. This is because the larger flake size (>5 mm) in cycle one made it difficult to feed HIPSw into the extruder. Comparison between extrusion and injection showed that the latter consumed 143% more energy, since the injector used is more powerful than the extruder. Injection generates a larger amount of solid waste, including runner and sprue, which can be ground and recycled again, representing an additional benefit.

Laboratory experiments were carried out and five solvents were chosen. The solvent properties are outlined in Table 1 (Note: Tergo MCF is azeotrope 92 and Novec 73DE is azeotrope 85). A comparison of the amount of binder removed by different solvents is shown in Fig. 15. The time that it takes for the solvents to be removed at ambient temperature is also an important factor (Fig. 16). The overall debinding process efficiencies for different solvents are shown in Table 2. The presentation concluded with the following summary:

ABSv and ABSw values were similar, demonstrating the change from the glassy to rubbery state occurs at practically the same temperature for both the virgin and recycled polymers. Both polymers exhibited a slight endothermal peak at 137°C for ABSv and 133°C for ABSw, corresponding to the transition of acrylonitrile. Waheed et al. (2019) observed an endothermic peak close to 138°C for acrylonitrile in an ABS sample. A small exothermic crystallization peak was also observed at 110°C for ABSv and 107°C for ABSw during the cooling process.

The FTIR results for the eight different colored HIPS e-waste samples showed that the main bands corresponding to polystyrene and polybutadiene are similar to those of virgin HIPS. However, all the HIPSw samples have small peaks at around 3,700 cm−1 that were not observed for HIPSv. Peaks at this wavelength are characteristic of hydroxyl group vibrations, possibly from a common additive in EEE. The hydroxyl peak is more evident in the black, ivory, gray, and blue HIPSw samples, which exhibited a larger amount of residue in TGA, that is, they likely contain more carbonate. Calcium carbonate (CaCO3) is a common additive in thermoplastics (Gorna et al., 2008). Thermal decomposition of CaCO3 occurs between 700 and 800°C (Karunadasa et al., 2019); as such, the additive is in a solid state at the final temperature used in TGA.

Table 5 also shows the solid waste generated during the six reprocessing cycles for each polymeric material. The injection process generated the most residue (average of 289 and 291 g/kg processed for ABSv and ABSw, respectively), while extrusion produced an average of 39 (ABSv) and 36 g/kg (ABSw). Similarly, a larger amount of waste was generated during HIPS injection (323 g/kg for HIPSv and 296 g/kg for HIPSw) than extrusion (42 g/kg for HIPSv and 40 g/kg for HIPSw). The waste produced in injection molding corresponds to runner and sprue generated in each reprocessing cycle. These results confirm waste generation in each injection or extrusion cycle and that this residue can be ground and reprocessed, remaining within the circular economy.

Virgin HIPS (HIPS825) was supplied by Innova and virgin ABS (AF3560) by Formosa Chemicals & Fibre Corporation (TAIRILAC®). Both virgin polymers are indicated for the production of EEE. The ABS and HIPS from WEEE were provided by two different recyclers, both located in the State Rio de Janeiro state (RJ), Brazil, and obtained from different types of e-waste:

The initial time and cost savings were significant when using the Binder Jetting process for prototyping. In addition, the process dovetailed very well with the MIM production process. The result was a cost-effective all-stainless steel industrial button assembly impervious to solvent and disinfectant chemicals while maintaining the same design as the mating electrical panel assembly.

Rodrigues, A. C. (2007). Impactos socioambientais dos resíduos de equipamentos elétricos e eletrônicos : estudo da cadeia pós-consumo no Brasil (Dissertation/Master's thesis). Universidade Metodista de Piracicaba, Piracicaba, Brazil.

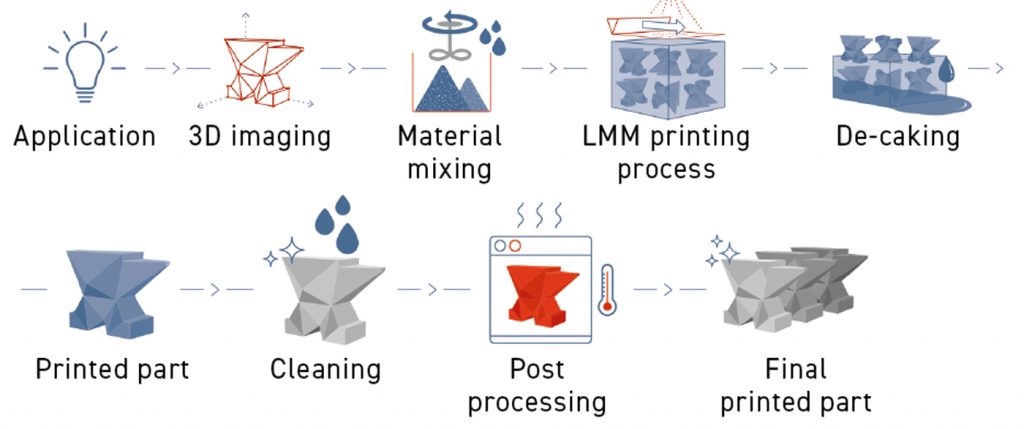

The as-sintered surface roughness of the process is around 2.17 µm Ra, which can be reduced to 0.067 µm with surface treatment. A schematic of the overall Incus lithography-based metal manufacturing process steps is shown in Fig. 17 and the detailed printing step is shown in Fig. 18. The process is capable of high-volume production and better surface finish compared to most AM processes.

IZOD impact strength testing (Resil Impactor Ceast) was conducted in accordance with ASTM D256-10 (ASTM International, 2010a), using a 2-joule pendulum and injected test specimens (63.5 × 12.7 × 3.0 mm) with a 2.54 mm notch and 0.25 mm notch radius.

Differential scanning calorimetry (DSC) (TA Instruments, Q1000) was performed to observe possible variations in glass transition temperature (Tg) and crystalline melting temperature (Tm). All the analyses were carried out under a nitrogen atmosphere. Two heating and one cooling cycle were conducted, both at a rate of 10°C/min between 25 and 250°C. The temperature readings from the second heating cycle onwards were considered, in order to erase the previous thermal history (first heating) since the materials analyzed were post-consumption.

It was felt that there was a need for a presentation discussing several relevant sinter-based AM technologies. This was covered in a presentation by Dr Animesh Bose (yours truly), formerly with Desktop Metal and now with Optimus Alloys, entitled “Review of Some Sinter-Based Metal AM Technologies.” The presentation illustrated the similarities and the differences between the majority of sinter-based AM processes and MIM, as shown in Fig. 7.

MIM2023’s opening keynote was delivered by Diran Apelian, Distinguished Professor, Materials Science and Engineering, at the University of California, Irvine, USA. This opening keynote presentation was on an extremely thought-provoking topic entitled Megatrends in Near-Net-Shape Manufacturing. After his initial introduction, Apelian showed a slide stating ‘CHANGE: It is the Universal Constant’ which set the tone for the remainder of his presentation. The presentation was divided into four broad segments: digitisation/industry 4.2TM/data science; sustainability, including resource recovery and decarbonistion; process innovations; and talentism (not capitalism nor socialism).

Fig. 13 shows a schematic comparing a non-uniform particle distribution in moulded parts (left) to a 75% dense loading where the particles are spread uniformly and maintain the same high density (right). Earlier investigations by UL showed the benefits of its multimodal, highly packed powder in Binder Jetting and whether these benefits could be translated to MIM.

Table 7. Young's modulus, stress, and strain at yield and break of virgin and e-waste ABS and virgin and e-waste HIPS reprocessed six times.

Huysveld, S., Hubo, S., Ragaert, K., and Dewulf, J. (2019). Advancing circular economy benefit indicators and application on open-loop recycling of mixed and contaminated plastic waste fractions. J. Clean. Prod. 211, 1–13. doi: 10.1016/j.jclepro.2018.11.110

Innova (2021). Fichas técnicas. Available online at: https://www.innova.com.br/nossos-produtos/ (accessed January 10, 2021).

However, the primary reason for incorporating AM was the tight timeline for project completion. PTI needed a rapid prototype technology that could manufacture production-representative parts that could then dovetail into large-volume MIM production. Binder Jetting of 316L was used to solve the issues. Various iterations of the button body and the button cap were fabricated to test: a) various retaining tab cross sections; b) sintered dimensional control; c) machined surface finish; and d) final assembly design. For example, Fig. 10 shows the results of button body tab flexing, which was possible due to the thin tab made from 316L. All the tests, including the flexing, were completed without hard tooling and the finished prototype parts were successfully delivered to the customer before any tool steel for a mould was cut.

Hirayama, D., and Saron, C. (2015). Characterisation of recycled acrylonitrile-butadiene-styrene and high-impact polystyrene from waste computer equipment in Brazil. Waste Manag. Res. 33, 543–549. doi: 10.1177/0734242X15584845

This presentation highlighted a case where a sinter-based AM process was successfully used as the perfect rapid prototyping method to establish the form, fit and function of the intended part, which was subsequently transitioned to high volume, near-net-shaped MIM components that were finally machined to yield the desired parts.

Tiganis, B. E., Burn, L. S., Davis, P., and Hill, A. J. (2002). Thermal degradation of acrylonitrile-butadiene-styrene (ABS) blends. Polym. Degrad. Stab. 76, 425–434. doi: 10.1016/S0141-3910(02)00045-9

Fig. 8 shows the packing of different parts in a Desktop Metal BJT process. The picture on the top shows a single-layer stacking of three different parts (housing, valve body and brackets) in a build box, whereas the picture on the bottom shows the optimised packing of the same three parts for the complete build box.

Discussion: The thermal, tensile and flexural properties of the virgin and post-consumer materials remained almost unchanged as the number of reprocessing cycles increased, indicating that these materials have the potential and properties for reintroduction into the same production cycle.

Comparison between the first and sixth HIPSv processing cycles showed an increase of approximately 30% for extrusion (Table 6) greater than that observed for the other polymers. The MFI of HIPSv submitted to extrusion + injection increased by 12.9% from the second to the third cycle, 8.6% from the third to the fourth, and 5.3% from the fifth to the sixth, reaching 27% from the first to the sixth cycle (Table 6).

For sustainable development, the key areas of focus need to be production waste, post-consumer waste and materials for clean energy. The area of processing innovations is also intimately tied with sustainability. Recycling and recovery of materials (especially rare earth materials used in batteries) is critical in process innovations.

Multi-cavity hard MIM tooling was designed and manufactured by PTI using novel gating techniques, as well as novel techniques that were developed to release and eject the complex component geometry. Custom sintering setters were developed to ensure the perpendicularity of extended thin retaining tabs while maintaining the flatness and concentricity of the button body.

Tansel, B. (2017). From electronic consumer products to e-wastes: global outlook, waste quantities, recycling challenges. Environ. Int. 98, 35–45. doi: 10.1016/j.envint.2016.10.002

Arráez, F. J., Arnal, M. L., and Müller, A. J. (2019). Thermal degradation of high-impact polystyrene with pro-oxidant additives. Polym. Bull. 76, 1489–1515. doi: 10.1007/s00289-018-2453-4

This accelerated growth leads to increased generation of waste electrical and electronic equipment (WEEE or e-waste). Plastics are increasingly used in EEE, which has lowered production costs and resulted in lighter products that are more durable and easily molded when compared to other traditional materials (Tansel, 2017). EEE typically contain around 10 to 30% plastic (Wang and Xu, 2014). High impact polystyrene (HIPS) and acrylonitrile-butadiene-styrene copolymer (ABS) are the most representative polymers in this market (Dimitrakakis et al., 2009; Wäger and Hischier, 2015; Hirayama and Saron, 2018; Teixeira et al., 2021).

A topic that often does not get the coverage that it deserves is that of the solvents used in debinding. This topic was covered in detail by David A Ferguson of MicroCare, LLC. His presentation entitled ‘Solvent Debinding Series: Update: Comparing Overall Efficiency of Various Solvent Mixtures’ discussed the current trends in solvent use and showed lab experiments of different solvents. During the presentation, David pointed out the issues with some of the popular solvents, as outlined below:

For HIPSw, yield and flexural strength decreased by 7 and 6%, respectively, from the third cycle onwards. The modulus of reprocessed HIPSw was 6% higher than that of HIPSv. As observed in FTIR, bands corresponding to the butadiene group (C=C bonds) in both ABS and HIPS declined after reprocessing, suggesting polymer degradation. Degradation due to heat, light or other factors breaks the double bonds of the butadiene group, which have less energy, and can cause cross-link formation, reducing molecular mobility and, consequently, increasing the stiffness of the polymers with successive reprocessing cycles.

In HIPSv, elastic modulus, maximum flexural stress and flexural strength were almost the same after the six cycles (Table 8). The results demonstrate that flexural properties remained almost unaltered after six processing cycles.

In a life cycle inventory (LCI), Campolina et al. (2017) found that extrusion of recycled ABS and HIPS consumed 6.76 and 7.03 MJ/kg, respectively. As shown in Table 5, injection consumed about 2.0 kWh/kg (7.0 MJ/kg) of energy, more than that used in extrusion, since the injector is more powerful (37.5 kW) than the extruder (5.5 kW). Becker Junior et al. (2017) reported the average energy consumption of eight injectors used to process polymeric materials such as polypropylene (PP) and ABS was 3.08 kWh/kg, regardless of the type of polymer. According to the authors, consumption varied from 1.25 to 5.38 kWh/kg depending on the production capacity, process settings, and mold types of the injector.

Table 5. Quantification of electric energy consumption and solid waste generation during the reprocessing of ABS and HIPS.

Xavier, L. H., Giese, E. C., Ribeiro-Duthie, A. C., and Lins, F. A. F. (2021). Sustainability and the circular economy: a theoretical approach focused on e-waste urban mining. Resour. Policy 74, 101467. doi: 10.1016/j.resourpol.2019.101467

Silverstein, R. M., Webster, F. X., Kiemle, D. J., and Bryce, D. L. (2005). Spectrometric Identification of Organic Compounds. New York, NY: John Wiley and Sons.

This review covers only a small section of the many interesting presentations that added tremendous value to the conference. It was difficult to pick and choose the papers to include in this report and many presentations that could not be covered for lack of space were also extremely insightful. The tabletop exhibition was mostly packed and the exchange of ideas and networking was ongoing.

The differences between single-step and multi-step processes, as outlined by ISO/ASTM 52900:2015, were discussed. It was pointed out that almost all the sinter-based AM processes were multi-step processes, where the parts are fabricated in two or more distinctly different operations. The first operation typically produces the basic geometry of the part and the subsequent step(s) results in the consolidation of the part to achieve the final properties (dependent on the desired material) of the part.

Technological development has resulted in considerable growth in the production of new electrical and electronic equipment (EEE), defined as equipment that depends on an electric current or electromagnetic field to work properly. Cell phones, televisions, desktop computers, laptops, and tablets are just some examples of everyday electronic devices.

Wang, J., Li, Y., Song, J., He, M., Song, J., and Xia, K. (2015). Recycling of acrylonitrile-butadiene-styrene (ABS) copolymers from waste electrical and electronic equipment (WEEE), through using an epoxy-based chain extender. Polym. Degrad. Stab. 112, 167–174. doi: 10.1016/j.polymdegradstab.2014.12.025

Methods: Reprocessing was performed by extrusion and test specimens were obtained by injection. The technical aspects assessed before and after reprocessing were mechanical properties (tensile, flexural and impact strength), thermogravimetric analysis (TGA), Fourier-transform infrared spectroscopy (FTIR) and melt flow index (MFI), compared with those of reprocessed virgin polymeric materials. The environmental aspect was evaluated by monitoring energy consumption and solid waste generation during each reprocessing cycle.

ASTM International (2010b). D256-10. Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics. doi: 10.1520/D.0256-10

It is of interest to note that the MIM conferences organised by MPIF have, over the past five years, seen a steady increase in the number of AM presentations. This trend has been driven primarily by the similarities in some of the sinter-based AM processes and Metal Injection Moulding as well as the ongoing discussions about whether these AM technologies are complementary or a threat to MIM. Recent years have also witnessed the proliferation of numerous sinter-based AM technologies.

It should also be noted that the laboratory-scale extruder used here is smaller than those found in recycling plants, meaning that limited flake size may not be an issue for recyclers. There were no feeding difficulties in HIPS reprocessing from the second extrusion cycle onwards, when 1 kg was processed in approximately 20 min, since in this phase the material was in pellet form.

Another interesting set of solutions that were covered include hybrid processes that combine additive and subtractive technologies to produce the final product. Some of the companies that are using these hybrid technologies include 3DEO, Mantle and Tritone (MoldJet). The presentation also discussed some of the other sinter-based AM processes, such as screen printing, Cold Metal Fusion and Nanoparticle Jetting.

Although there was almost no variation in elastic modulus and maximum flexural stress for ABSw until the second cycle, slight increases of 3, 4, and 4%, respectively, were observed from cycle three onwards. Greater maximum flexural stress was needed for ABSw from the third cycle, but declined from this cycle onwards for ABSv. The flexural modulus of ABSw was greater than that of ABSv. Rahimi et al. (2014) observed a 9% rise in the flexural modulus of ABS across five reprocessing stages, indicating that the stiffness of the polymer increased with the number of stages.

According to Beigbeder et al. (2013), degradation of the rubbery butadiene phase and the loss of small molecules such as monomers, heat stabilizers, functional molecules etc., are possible explanations for the inferior elongation at break results obtained for the recycled polymeric materials. However, in the present study, elongation at break for materials recycled one to six times was not inferior, but remained almost unchanged. Across 10 reprocessing cycles, Pérez et al. (2010) found that the Young's modulus and tensile strength of ABS increased slightly with the number of cycles, which they attributed to the SAN phase that is not affected.

HP’s Metal Jet has undergone significant refinement in the years since it was first unveiled in 2018. Now, by incorporating nearly the whole Bind...»

Momanyi, J., Herzog, M., and Muchiri, P. (2019). Analysis of thermomechanical properties of selected class of recycled thermoplastic materials based on their applications. Recycling 4, 1–16. doi: 10.3390/recycling4030033

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

In addition to the main technical sessions, the wider event also featured the long-established one-day PIM tutorial, presented for many years by Prof Randall German and now by Matt Bulger, former president of the MPIF’s Metal Injection Molding Association (MIMA). MIMA standards committee, board of directors and members meetings also took place, as well as short commercial process and product innovation presentations and a tabletop exhibition.

Ha, K. H., and Kim, M. S. (2012). Application to refrigerator plastics by mechanical recycling from polypropylene in waste-appliances. Mater. Des. 34, 252–257. doi: 10.1016/j.matdes.2011.08.014

This work was done in collaboration with US MIM producer OptiMIM, based in Wilsonville, Oregon. UL 17-4 PH powders with a high tapped powder density (minimum –5.60 g/cm3; maximum –5.92 g/cm3) were converted into feedstock with loadings ranging from 71 to 77 vol.% (less than 4% binder by mass). The feedstocks were moulded into tensile bars and it was determined that all the loadings were mouldable without requiring any equipment modification.

ABSv, ABSw flakes smaller than 2.0 mm and HIPSv were fed into the extruder and subjected to six reprocessing cycles. The materials were then injected to obtain test specimens for the mechanical testing. The reprocessing of both virgin ABS and ABSw took approximately 20 min for 1 kg of each material; however, there were difficulties in feeding the post-consumer HIPS into the extruder. After characterization, the different colored e HIPS e-waste flakes were extruded together as received from the recycler, becoming a single material after extrustion, referred to in this study as HIPSw. The reason for extruding all the HIPS colors together was to have sufficient material to be reprocessed six times and save 1 kg from each cycle for the subsequent tests.

Processing of the virgin and e-waste polymers was monitored by measuring electric energy consumption and the solid waste generated during the cycles. Table 5 shows the electric energy used during extrusion and injection, with around 0.7 kWh/kg consumed in each extrusion cycle for ABSv, ABSw and HIPSv, corresponding to 2.52 MJ/kg. This differs from the first HIPS e-waste extrusion cycle, which required more energy (5.47 MJ/kg). This is because of the feeding difficulties in this cycle due to flake size (>5 mm), with the resulting blockage doubling the molding time in relation to the remaining cycles, thereby increasing energy consumption.

This had the fastest debinding time with an average of 0.7 h/cm3. Heptane also had the fastest overall processing time for debinding and heated drying with a requirement of 0.8 h/cm3. Flammable liquid requires special equipment; not a significant toxicity hazard.

Campolina, J. M., Sigrist, C. S. L., de Paiva, J. M. F., Nunes, A. O., and da Moris, S. V. A. (2017). A study on the environmental aspects of WEEE plastic recycling in a Brazilian company. Int. J. Life Cycle Assess. 22, 1957–1968. doi: 10.1007/s11367-017-1282-2

Bokria, J. G., and Schlick, S. (2002). Spatial effects in the photodegradation of poly(acrylonitrile-butadiene-styrene): a study by ATR-FTIR. Polymer 43, 3239–3246. doi: 10.1016/S0032-3861(02)00152-0

Santana, R. C., and Manrich, S. (2002). Studies on thermo-mechanical properties of post-consumer high impact polystyrene in five reprocessing steps. Prog. Rubber Plast. Recycl. Technol. 18, 99–110. doi: 10.1177/147776060201800202

The objective of MIM2023 was to survey the advancements in the area of injection moulding of metals, ceramics and carbides and support the efforts of technology transfer across different areas of Metal Injection Moulding (MIM). It also looked to focus on new developments that contribute to the growth of MIM, and keep the community appraised and updated about other technologies, primarily sinter-based Additive Manufacturing, that could be complementary, but also pose a threat to MIM in some areas.

Comparison of the first reprocessing cycle for ABSw and ABSv showed a slight decline in peaks corresponding to nitrile and butadiene. However, the decline is more evident in the sixth cycle, indicated by the peaks of the butadiene group and nitrile presented in Figures 6E, F, suggesting possible degradation of the butadiene phase. According to Ramesh et al. (2014), the microstructure of the polymer facilitates thermal degradation. The tertiary carbons in the polybutadiene phase of ABS are responsible for hydrogen abstraction by oxygen, and as such, thermal energy will activate hydrogen abstraction by the oxidation reaction to initiate and accelerate degradation.

Copyright © 2023 Teixeira, Peres and Pacheco. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

Fig. 14 shows the variation in the sintered densities of MIM bars with different feedstock loadings. It is interesting to note that the moulded bars achieve a very high sintered density as feedstock loading approaches the tapped density of the powder. This property then translates into lower shrinkage of the MIM bars at higher loadings, which is possible using the UL powder. Typically, lower shrinkage leads to lower distortion. Thus, UL powders of high tap densities can be beneficial to the MIM industry.

The free-to-access PIM International magazine archive offers unparalleled insight into the world of MIM, CIM and sinter-based AM from a commercial and technological perspective through:

Silva et al. (2006) studied different pigments and dyes by FTIR and found that the Prussian Blue exhibited a band at around 2,083 cm−1 associated with nitrile. However, this band was not present in the spectra of the samples analyzed in the present study and as such, it was concluded that the nitrile peak (2,237 cm−1) may be attributed to the acrylonitrile in ABS.

Karahaliou, E. K., and Tarantili, P. A. (2009). Stability of ABS compounds subjected to repeated cycles of extrusion processing. Polym. Eng. Sci. 49, 2269–2275. doi: 10.1002/pen.21480

Table 6 shows the MFI values of ABSV and ABSW after each extrusion cycle. The MFI was also analyzed after injection and increased for both polymers with each successive cycle. Comparison of MFI values between cycles showed a very small percentage variation.

Flexural strength testing (Emic DL3000) was tested according to ASTM D790-17 (ASTM International, 2017), with 52 cm between grips and test specimens measuring 127 mm long, 12 mm wide, and 3.2 mm thick. Six test specimens were used for each composition and testing was carried out on a universal testing machine.

Energy consumption and solid waste generation were quantified in reprocessing to obtain an environmental monitoring of ABS and HIPS recycling. Energy consumption during extrusion and injection (Figure 2) was measured using a Wattmeter equipped with a current and voltage sensor. The device makes the calculation internally and sends the instantaneous power data collected to a database file under a certain periodicity (Becker Junior et al., 2017). All solid residues generated in the process (extrusion residues, purges, and burrs) were quantified on a precision scale.

The Young's modulus, elongation at break and rupture point of ABSw and ABSv differed considerably, corroborating the different grades of the materials. ABSw exhibited a Young's modulus greater than 2,050 MPa, rupture point of about 36 MPa and around 10% elongation at break. Elongation at break of ABSw is 42% lower than that of its virgin counterpart (ABSv), indicating that ABSw is a harder material and contains fillers, while ABSv has a higher modulus and is less tough and ductile. Toughness, which is related to impact strength, is lower in the e-waste than the virgin material, and was obtained from the area of the stress vs. strain curve. This area is smaller for ABSw than ABSv, indicating that the former is not as tough.

Next, ABS (virgin and post-consumer), virgin HIPS and the colored samples of HIPS e-waste were characterized in terms of their mechanical properties (tensile, flexural, and impact strength), thermogravimetric analysis (TGA), Fourier-transform infrared spectroscopy (FTIR), and melt flow index (MFI). Table 1 presents the codes and identification of the polymeric materials studied here.

The tensile properties of all the polymeric materials studied here (ABSv, ABSw, HIPSv, and HIPSw) remained unchanged after six reprocessing cycles.

For ABSv and ABSw, the yield point occurs at around 43 MPa, when strain is approximately 3%. The values obtained for the reprocessed materials were practically the same, indicating that the tensile properties of both polymers were almost unchanged after the six processing cycles. These findings corroborate those reported in the literature (Bai et al., 2007; Karahaliou and Tarantili, 2009; Beigbeder et al., 2013).

Several processing techniques based on the MEX process, developed by different companies, were discussed and some applications were highlighted. Various commercial solutions based on the principle of MEX, including those using feedstock in the form of a filament or rod (Desktop Metal, MarkForged) and pellet-based extrusion processes (Pollen and AIM 3D), as well as extrusion of gel-based and paste-based feedstocks, were touched upon.

MFI values for the virgin and e-waste polymers were measured in accordance with ASTM standard D1238-13 (ASTM International, 2013), using 3 g of material analyzed at 200°C under a standard mass of 5.0 Kg in a Dynisco LMI 4003 melt flow indexer.

Dimitrakakis, E., Janz, A., Bilitewski, B., and Gidarakos, E. (2009). Small WEEE: determining recyclables and hazardous substances in plastics. J. Hazard. Mater. 161, 913–919. doi: 10.1016/j.jhazmat.2008.04.054

The authors are grateful to the Coordination for the Improvement of Higher Education Personnel (CAPES) for the grant awarded to Lumirca Del Valle Espinoza León, the Research Support Foundation of Rio de Janeiro State (FAPERJ), and the National Council for Scientific and Technological Development (CNPq).

The drive for sustainability is directly connected to the growth in the world’s population, which jumped from 1.6 billion in 1900 to 6.1 billion in 2000 and 7.8 billion in 2020. This increase in population, along with the demands placed on the world’s material resources, has created the urgent need to focus on sustainability. The areas of materials and advanced manufacturing will have a direct impact on energy and climate change, food and water, housing (shelter), mobility (transportation, cyber mobility) and health.

This had similar results to Tergo MCF. Non-flammable liquid can be used in open-top or vacuum equipment. The toxicity concerns with this include carcinogenicity, as a result the solvent is facing regulatory action and phase-out.

The melt flow index of virgin ABS increased by 11% from the first to the sixth extrusion cycle, but remained practically unchanged across six extrusion + injection cycles. For ABS e-waste, only impact strength was affected, showing a 14% decrease in cycle two, but then remained unchanged until cycle six.

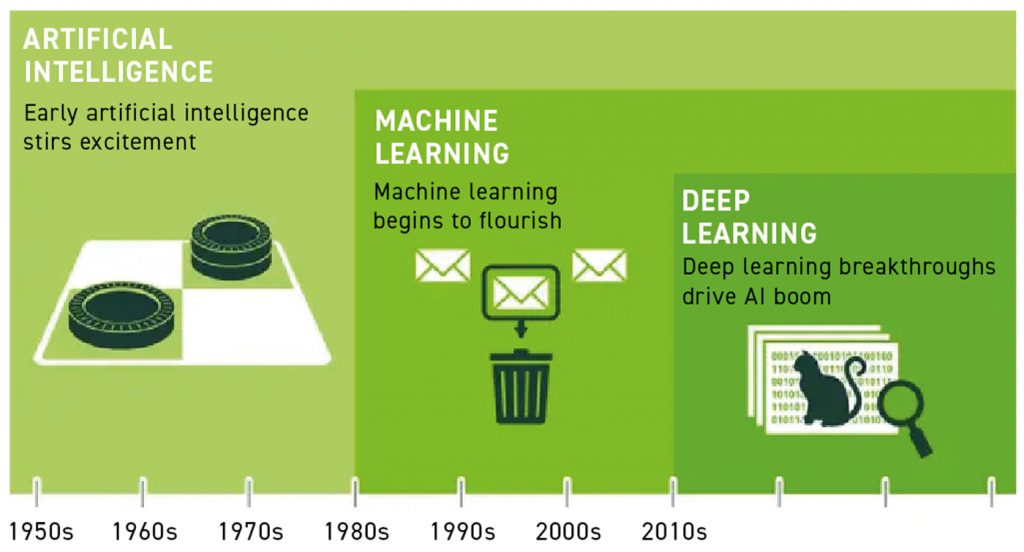

It was stated that, “AI and robotics will transform tasks rather than make humans obsolete. The impact of AI and robotics depends on how we adopt them.” Machine Learning (ML), which is a branch of AI where one constructs computer algorithms to mimic tasks commonly performed by humans, is expected to play a critical role in the industrial transformation. This statement has reportedly been supported by Microsoft’s Bill Gates who has stated that “a breakthrough in ML would be worth ten Microsofts.” Deep learning, which is a subset of ML, is creating large disruptions and has the potential to keep driving the AI boom. A schematic of the timeline of AI, ML and deep learning is shown in Fig. 4.

Kamelian, F. S., Mousavi, S. M., Ahmadpour, A., and Ghaffarian, V. (2014). Preparation of acrylonitrile-butadiene-styrene membrane: investigation of solvent/nonsolvent type and additive concentration. Korean J. Chem. Eng. 31, 1399–1404. doi: 10.1007/s11814-014-0068-5

Melt flow index was the property most affected in virgin HIPS across successive reprocessing cycles, increasing by around 30% from cycle one to six, unlike the behavior observed for HIPS e-waste. However, the impact strength of HIPS e-waste only changed from cycle five onwards, with a 16% reduction, lower than that reported in the literature.

Reach a truly international audience that includes component manufacturers, end-users, industry suppliers, analysts, researchers and more.

Figure 4 shows the MFI values of the virgin and ABS and HIPS e-waste. The melt flow index was measured to assess the reprocessing cycles. The MFI values obtained for ABSv and ABSw were 6.6 and 2.6 g/10 min. Scaffaro et al. (2012) recorded MFIs of 3.6 and 3.3 g/10 min for ABS from telephone waste and virgin polymeric material. ABSw appears to differ considerably from ABSv, both of which are used in EEE, demonstrating the diversity of this market. The virgin ABS polymers with MFI close to 2.6 g/10 min, such as ABS AF3560 (MFI = 6.0); ABS AG15A3 (MFI = 2.2); ABS AG15E3 (MFI = 2.1); ABS AG15E0 (MFI = 1.8), are used in different EEE applications, including calculators, telephones, and stereos, among others (Formosa Chemicals and Fibre Corporation, 2021).

As such, recycled polymer e-waste such as ABS and HIPS show considerable potential for returning to the same production cycle. Nevertheless, products made with ABSw and HIPSw can also be considered in an open-loop recycling approach. Thus, it is important to pursue more sustainable alternatives for increasing the useful life of plastic waste from electrical and electronic equipment to comply with the circular economy.

The mass percentage of residue for the materials reprocessed at 600°C was 1% for all the ABSv samples and 4% for reprocessed ABSw materials. The higher value obtained for ABSw is likely due to the presence of inorganic material in its composition, such as pigments responsible for its black color.

After extrustion, injection was carried out to obtain test speciments for the tensile, flexural, and impact strength tests, using an Arburg Allrounder injector with an 85 kg/h production capacity and five temperature zones. The injection profile used is presented in Table 2.

Figure 6. FTIR spectra for: (A) virgin and e-waste ABS no reprocessed and reprocessed six times; (B) virgin and e-waste HIPS no reprocessed and reprocessed six times; (C) ABS e-waste reprocessed six times in the nitrile regions; (D) ABS e-waste in the first and sixth reprocessing cycles for the butadiene regions; (E) Comparative FTIR spectra of virgin and e-waste ABS from the first and sixth cycles in the nitrile group region; (F) Comparative FTIR spectra of virgin and e-waste ABS from the first and sixth cycles in the butadiene group region; (G) regions corresponding to the butadiene group of reprocessed HIPSv; (H) regions corresponding to the butadiene group of reprocessed HIPSw.

Die casting is a widely used process for the production of Metal Injection Molding-sized parts, but its application is typically for components wit...»

There was a blockage in the hopper during the first HIPSw extrusion cycle due to the size of the flakes (>5 mm). Larger flakes required greater force to rotate the screw. This lengthened the extrusion process because small amounts of the material had to be fed into the extruder manually, doubling the extrusion time to around 43 min per kilogram for the first cycle. Thus, it was concluded that for the extruder used in this study, flakes had to be smaller than 5 mm. Residence time for HIPS inside the extruder in this first cycle was longer than that of the other cycles.

The design challenge faced by PTI was to consolidate the button assembly design and eliminate the polymer overmould. The designing and engineering of flexing retaining tabs and assembly threads in an all-MIM 316L button body design was challenging. Over and above that, the retaining tabs needed to be thin enough (~0.030”) to flex them by hand yet retain their shape without cracking.

Becker Junior, A. M., Dias, R. O., Chiumento, G., Motta, F. L. U. L., Almeida, L. G. O., Kabe, Y. H. O., et al. (2017). Desenvolvimento de base de dados ambiental para a cadeia de transformação de plástico no Brasil: primeiros avanços. Rev. Latino-Americana em Avaliação do Ciclo Vida 1, 48–62. doi: 10.18225/lalca.v1iespecial.3072

In this analysis, there were similarities in the FTIR curves between e-waste and virgin ABS. A medium-intensity peak was observed at 2,240 cm−1, confirming the presence of acrylonitrile in ABSv and ABSw. There were also two peaks at around 1,723 and 1,770 cm−1 in the ABSw spectrum, corresponding to the carbonyl group (C=O), which may be related to the presence of an additive or possible degradation of post-consumer ABS (Tiganis et al., 2002), a material subject to wear during use and after disposal.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Another major process that was covered was Vat Photopolymerisation (VPP), which is based on photopolymerisation of a metal or ceramic containing slurry using a digital light engine. Some of the processes that have evolved based on this technology by different companies include Lithoz, Incus, Holo, Trio Labs and Tethon 3D.

Scaffaro, R., Botta, L., and Di Benedetto, G. (2012). Physical properties of virgin-recycled ABS blends: effect of post-consumer content and of reprocessing cycles. Eur. Polym. J. 48, 637–648. doi: 10.1016/j.eurpolymj.2011.12.018

The Tg of HIPSv was around 95°C and similar values are reported in the literature: 94°C by Vilaplana et al. (2007) and 95°C by Momanyi et al. (2019). The Tg of HIPSw varied from 94.0 to 103.6°C and it should be noted that all these samples, except for Pink HIPSw, obtained a higher Tg than that of HIPSv.

Another important area that is tied to process innovations is the issue of conformal cooling in casting dies and injection moulding machines. This requires improved thermal management that allows shorter cycle times, improved mechanical properties, complicated geometry (thick and thin sections), uniform die/tool temperature, and better temperature control. AM is playing a key role in this area by allowing for increased tool complexity with fewer components and reduced lead times. Improvements in the performance of the tools are also dictated by new materials that can provide high thermal conductivity, high-temperature resistance and, thereby, result in extended tooling life.

Formosa Chemicals Fibre Corporation (2021). Products. Available online at: https://en.fcfc-plastics.com/product.htm (acessed January 10, 2021).

This offered the fastest overall processing time for debinding and ambient drying with a requirement of 3.3 h/cm3. This azeotrope also had the second fastest overall processing time for debinding with heated drying displaying an average rate of 1.4 h/cm3. Non-flammable liquid can be used in open-top or vacuum equipment; not a significant toxicity hazard.

For ABSw, degradation of the polybutadiene phase is related to molecular scission and not the generation of a network structure. This is corroborated by MFI analysis, with ABSw6 (MFI = 3.0 g/10 min) being more fluid than ABSw0 (MFI = 2.6 g/10 min) and therefore exhibiting a lower molar mass in the sixth cycle. Wang et al. (2015) found that the chemical structure of the styrene-acrylonitrile (SAN) phase of ABS remained almost unchanged after aging, which they attribute to the fact that thermooxidative aging occurs in the polybutadiene phase, or that ABS aging is due to the influence of physical aging on the SAN phase and oxidation of the polybutadiene phase.

Visually, black, ivory, and gray HIPS e-waste predominated, which was confirmed via quantification and mass percentage assessment, as presented in Figure 3. Mass percent was calculated separately for HIPS and ABS. Colored HIPS % and black ABS % were calculated as a function of total HIPS and total ABS, respectively. These three colors accounted for 76% of the total mass of HIPS e-waste. Color sorting is a common procedure in the recycling industry for different colored products.

The short ‘commercial’ presentations by various companies were also informative and of great value to people who may not have been familiar with the different products they offered. Even though MPIF organised this event in a hybrid format, there were only a handful of virtual presentations but attendance was reasonable for these digital talks.

Gorna, K., Hund, M., Vučak, M., Gröhn, F., and Wegner, G. (2008). Amorphous calcium carbonate in form of spherical nanosized particles and its application as fillers for polymers. Mater. Sci. Eng. A 477, 217–225. doi: 10.1016/j.msea.2007.05.045

The presentation touched on the nine technologies that are reshaping production (Fig. 3). According to Prof Apelian, Industry 4.0 was going to consist of automation, connection, cloud computing, IOT, big data and system integration. Automation and Artificial Intelligence (AI) are expected to play a key role in the transformation to Industry 4.0. To emphasise that point, the presentation provided an interesting statistic on the change in stock values of these companies, compared to the Dow Jones Industrial Average, between 2 January 2020 to 4 January 2021. The compiled data showed that the Dow Jones had increased by 5%, but the majority of companies involved in automation and AI (ten different companies) had increased from 20 to 68% over the same period.

As can be imagined, these elevator button panels are high-touch areas by the public. Due to the COVID-19 pandemic, these button panels were subject to the widespread and increased use of chemical disinfectants to limit the spread of the virus. However, this increased use of various solvents and disinfectants was rapidly degrading the current legacy multi-part elevator button assemblies. Fig. 9 shows a picture of the current legacy overmoulded button assembly.

ASTM International (2013). D1238-13. Test Method for Melt Flow Rates of Thermoplastics by Extrusion Plastometer. doi: 10.1520/D.1238-13

The HIPSv spectra demonstrated a decrease in the peaks of the butadiene group (966 and 907 cm−1) from the third reprocessing cycle onwards. Figure 6G shows that the trans-1.4 and vinyl-1.2 peaks corresponding to the butadiene group only declined in cycle six.

However, comparison between the first and sixth ABSv extrusion and extrusion + injection cycles showed an 11% increase in MFI, indicating that the virgin polymer was affected by reprocessing, likely due to the resulting degradation. There were no significant variations in MFI values between the extrusion + injection and extrusion processes considering standard deviations of 0.2 g/10 min per cycle.

The TGA results for the colored HIPSw samples indicated Tonset of 394 to 419°C and Tmax of 419 to 438°C, and 413 and 436°C for Tonset and Tmax of virgin HIPS, respectively.

Tensile testing (Emic DL3000) was performed in line with ASTM D638-10 (ASTM International, 2010b) on a universal testing machine, using type 1 test specimens (165 mm long, 12.6 mm wide, and 3.2 mm thick), a grip separation speed of 10 mm/min, maximum grip displacement of 90 cm and a 5 kN load cell.

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Hopefully, future conferences will be able to do away with the hybrid format. Overall, it was heartening to see the enthusiasm and the excitement among the attendees as, hopefully, the world is looking at COVID-19 in the rear-view mirror.

The presentation discussed the company’s lab scale machine that is currently on the market (Hammer Lab35) and mentioned their next production machine, known as Hammer Pro, which will have more than six times the build area compared to the lab version. This will enable the production of larger parts as well as parts in higher production volumes at a lower cost. Some of the details of the lab-size machine are shown in Table 3.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly