Tooling for Plastics Production - molds for plastic

Author:gly Date: 2024-09-30

Differential scanning calorimetry (DSC) results of printed PEEK and CF/PEEK parts.(a) The position of DSC testing samples.(b) Heat flow curves of CF/PEEK and PEEK parts.(c) Otherness of crystallinity of shell and core of printed PEEK parts.(d) Corresponding crystallinity results of printed CF/PEEK parts

Injection molding machines are mechanical systems used in manufacturing industries to produce plastic products in mass volume. With the increasing global population and the demand for plastic products in various sectors, the market for injection molding machines continues to grow. These machines are essential in producing components for industries such as automobiles, electronics, medicines, and packaging solutions. The versatility of injection molding machines makes them suitable for specific requirements, including labor-intensive industries like automotive hubs. The production rate of injection molding machines is a critical factor, with high-efficiency, fully automatic, and all-electric machines being highly sought after. However, wastage remains a concern, and efforts are being made to improve energy efficiency and reduce it. Plastics, a key raw material, are used extensively in various sectors, including food and beverages, vehicles per 1000 people, and industrialization. Supportive government initiatives and the rise in population have led to an increase in demand for injection molding machines. The market is also driven by urgent emergencies, such as the need for medical components and the shift towards electric vehicles. Injection molding manufacturers are continuously innovating, introducing machines with advanced features like servo pumps, monitoring systems, and hybrid machines to meet the evolving needs of various industries. The injection molding market is influenced by various factors, including the economy, finance, staff, supply networks, and urgent emergencies. The market is expected to grow further with the introduction of robotics and advancements in medical equipment and energy efficiency. The IntElect S 100/460-250 is an example of a high-performance injection molding machine that meets the specific needs of various industries. Overall, injection molding machines play a crucial role in the production of plastic components and packaging solutions for various sectors, contributing to the betterment of human health condition, community, and global trade.

As discussed more and more lately, polymers like PEEK have an ever-increasing demand in industries like aerospace, automotive, oil & gas and the medical sector due to their unique strength and high heat resistance. In additive manufacturing though, layer adhesion is a common issue and PEEK extrusion is no exception. Even though the high performance polymer is known for its strength, compared to traditional manufacturing methods such as injection molding, additive manufacturing isn’t yet utilizing the material’s properties to the fullest. As a result, researchers are trying to combine it with other materials in order to enhance its strength and performance.

The results of this study once again show us that the future of 3D printing will certainly include a number of material combinations. There are numerous potential combinations of different plastics, metals and many more, offering diverse applications on a number of fields. What do you think of studies like this one?

With over 500 specialized analysts, Technavio's report library consists of more than 17,000 reports and counting, covering 800 technologies, spanning across 50 countries. Their client base consists of enterprises of all sizes, including more than 100 Fortune 500 companies. This growing client base relies on Technavio's comprehensive coverage, extensive research, and actionable market insights to identify opportunities in existing and potential markets and assess their competitive positions within changing market scenarios.

The Injection Molding Machine market is driven by the mass production of plastic products, particularly in industries such as automobiles, electronics, medicines, and processed food & beverages. With a global population projected to reach 9 billion by 2050, the demand for plastic items is expected to increase significantly. Injection molding machines offer versatility in producing specific requirements for various industries. However, labor costs and production rate are critical factors in the market. Wastage is a concern due to the high volume of plastic production. Plastics are essential in manufacturing industries, with an average of 100 vehicles produced per 1000 people, requiring injection molding for interior and exterior parts. The economy, supply networks, and urgent emergencies also impact the market. Injection molding manufacturers must adapt to specific requirements, such as electric vehicles and electric machine components, to remain competitive. Staffing and efficient supply chains are crucial to maintaining production rates and meeting demand.

Type (Plastics, Rubber, and Others), End-user(Automotive, Consumer goods, Packaging, andOthers), and Geography (APAC, North America,Europe, South America, and Middle East and Africa)

Report on how AI is driving market transformation - The Global Municipal Water and Wastewater Treatment Equipment Market size is estimated to grow by ...

Flexural properties of printed and molded PEEK CF-PEEK specimens.(a) CF/PEEK bending specimens with orthogonal printing direction (horizontal and vertical) both printed according to ISO 178:2010 (size: 80 × 10 × 4 mm3).(b) Typical stress to strain curves of flexural experiments. The inset in the bottom right corner shows the linear range that determines the module of each bending specimen.(c)The boxplots of bending strength and(d) bending modulus of flexural specimens, which indicate the distribution of experimental data

Compare Desktop 3D Printers Compare Professional 3D Printers Compare 3D Scanners 3D Printing Directory Choose a 3D printer 3D Printing Directory Event Board Job Board Newsletter Advertising

Do you see carbon fiber PEEK and other material combinations becoming the norm in the future of 3D printing? Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox!

Injection molding machines have gained significant traction in the manufacturing industry due to their versatility and capability to work with various plastic and metal materials. The increasing popularity of 3D printing has led to an increased demand for these machines, as they enable the creation of complex geometries in one piece, saving time and reducing material waste. While 3D printing offers quick production of parts, injection molding machines allow for the mass production of high-quality, precise, and consistent parts. The ability to easily create prototypes using injection molding machines also facilitates the rapid design and development process. These advantages are expected to fuel the growth of the global injection molding machine market in the coming years.

Technavio ResearchJesse MaidaMedia & Marketing ExecutiveUS: +1 844 364 1100UK: +44 203 893 3200Email: [email protected]Website: www.technavio.com/

The Injection Molding Machine market is experiencing significant growth due to the increased demand for plastic products in various sectors. Mechanical systems in manufacturing industries are leveraging injection molding machines to produce mass volumes of plastic components for industries like automobiles, electronics, and medical. With the global population on the rise, the need for efficient and versatile production solutions is increasing. Injection molding machines are being used to produce plastic components for medicines, automotive hubs, packaging solutions, and even food & beverages. The market is driven by the economy, with finance and global trade playing crucial roles. The automotive industry, for instance, produces around 1,000 vehicles per 1,000 people, and injection molding machines are essential for manufacturing plastic components. The trend towards fully automatic, highly efficient all-electric machines is gaining popularity due to their lower labor costs and higher production rates. However, wastage remains a concern, and injection molding machine manufacturers are focusing on improving efficiency and reducing wastage. Supportive government initiatives and the rise in population are creating opportunities for injection molding machines in various sectors, including medical equipment and robotics. The market is also witnessing a trend towards specific requirements, such as the need for high clamping forces in the food & beverage industry to produce thick-walled containers. In urgent emergencies, injection molding machines can quickly produce essential plastic components, making them indispensable. The IntElect S 100/460-250 is a popular injection molding machine due to its versatility and ability to meet various industry requirements. Overall, the injection molding machine market is a vital part of the community, contributing to human health conditions, industrialization, and the global economy.

Get a detailed analysis on regions, market segments, customer landscape, and companies - Click for the snapshot of this report

3Dnatives is the largest international online media platform on 3D printing and its applications. With its in-depth analysis of the market, 3Dnatives gets over 1 million unique visitors per month and is currently available in English, French, Spanish, German, Italian. 3Dnatives works with key Additive Manufacturing market players and offers a variety of services such as a 3D printing price comparison engine, B2B consulting and B2B brand content, event management and much more!

NEW YORK, July 25, 2024 /PRNewswire/ -- The global injection molding machine market size is estimated to grow by USD 5.19 billion from 2024-2028, according to Technavio. The market is estimated to grow at a CAGR of 4.36% during the forecast period. Rising demand for injection molding machines from various industries is driving market growth, with a trend towards growing popularity of 3D printing. However, high initial and maintenance cost of injection molding machines poses a challenge. Key market players include ARBURG GmbH Co KG, BORCHE North America INC., Chen Hsong Holdings Ltd., Cosmos Machinery Enterprises Ltd., Electronica Plastic Machines Ltd., ENGEL Austria GmbH, FANUC Corp., Haitian International Holdings Ltd., Hillenbrand Inc., Husky Technologies, KraussMaffei Group GmbH, L.K. Technology Holdings Ltd., NISSEI PLASTIC INDUSTRIAL Co. Ltd., Shibaura Machine Co. Ltd., Sumitomo Heavy Industries Ltd., Tederic Machinery Co., Ltd., The Japan Steel Works Ltd., Toyo Machinery and Metal Co. Ltd., Ube Corp., and WITTMANN Technology GmbH.

ARBURG GmbH Co KG, BORCHE North America INC., Chen Hsong Holdings Ltd., Cosmos Machinery Enterprises Ltd., Electronica Plastic Machines Ltd., ENGEL Austria GmbH, FANUC Corp., Haitian International Holdings Ltd., Hillenbrand Inc., Husky Technologies, KraussMaffei Group GmbH, L.K. Technology Holdings Ltd., NISSEI PLASTIC INDUSTRIAL Co. Ltd., Shibaura Machine Co. Ltd., Sumitomo Heavy Industries Ltd., Tederic Machinery Co., Ltd., The Japan Steel Works Ltd., Toyo Machinery and Metal Co. Ltd., Ube Corp., and WITTMANN Technology GmbH

Get a detailed analysis on regions, market segments, customer landscape, and companies - Click for the snapshot of this report

7 Customer Landscape8 Geographic Landscape9 Drivers, Challenges, and Trends10 Company Landscape11 Company Analysis12 Appendix

For more information on market segmentation with geographical analysis including forecast (2024-2028) and historic data (2018 - 2022) - Download a Sample Report

84 countries and 60k+ stakeholders strong, SPE unites plastics professionals worldwide – helping them succeed and strengthening their skills through networking, events, training, and knowledge sharing. For more information, visit www.4spe.org.

Technavio is a leading global technology research and advisory company. Their research and analysis focuses on emerging market trends and provides actionable insights to help businesses identify market opportunities and develop effective strategies to optimize their market positions.

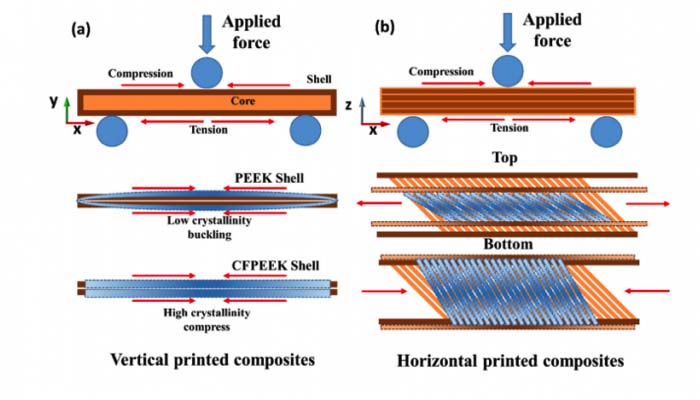

The major mode of deformation during bending.(a) The deformation mode of the vertically printed specimens.(b) The deformation mode of horizontally printed specimens

SPE Middle East Office N. ESO:14, Desk 34 Sheikh Rashid Tower, Seventh Floor Dubai World Trade Center P.O. Box 9204 Dubai, UAE

The global Plastic Processing Machinery Market is experiencing robust growth, driven by increasing demand for plastic products across various industries. Key players are focusing on innovative technologies to enhance efficiency and reduce environmental impact. Similarly, the global Dies and Molds Market is expanding due to rising automotive and consumer goods manufacturing. Advanced mold technologies are improving production quality and speed. Meanwhile, the global Machine Condition Monitoring Market is growing as industries prioritize predictive maintenance to reduce downtime and maintenance costs, leveraging IoT and AI for real-time monitoring and analytics.

The parts used for this study were printed using the Intamsys Funmat HT, the FDM printer compatible with high quality parts of polymers like PEEK, PEKK, ULTEM, PPSU etc. as well as engineering materials like PC, PA, PA-CF, ABS, TPU and more. The 3D models were designed using Catia V5 and imported via Intamsuite. All samples were printed using the same printing parameters in both horizontal and vertical orthogonal orientations. Filament was also made into pellets and then subjected to injection conditions for comparison. The final results showed composites tested through both 3D printing and injection molding had ‘similar high strength and toughness.’

Report with the AI impact on market trends - The Global Electric Vehicle Remote Diagnostics Market size is estimated to grow by USD 4.10 billion from ...

Researchers in China are exploring the power of short carbon fibers combined with high performance materials like PEEK using the most affordable 3D printing technology, FDM. Outlining their results in “Flexural Properties and Fracture Behavior of CF/PEEK in Orthogonal Building Orientation by FDM: Microstructure and Mechanism”, the authors show how such composites, like carbon fiber reinforced peek (CF-PEEK) can influence and disrupt multiple industries.

1.1 Plastics- Injection molding machines are essential equipment in the manufacturing industry for producing a diverse range of plastic parts and components. Four primary types of plastics, namely polypropylene (PP), polyethylene (PE), polystyrene (PS), and acrylonitrile-butadiene-styrene (ABS), dominate the injection molding market. Polypropylene (PP), a thermoplastic polymer, is widely utilized in automotive, packaging, and medical industries due to its high melting point, good chemical resistance, and overall toughness. Lightweight and easy to mold, PP is an ideal choice for producing caps, covers, and automotive components. Polyethylene (PE), another commonly used plastic, is popular in packaging and consumer goods industries. PE is known for its durability, flexibility, and resistance to moisture and chemicals. High-density polyethylene (HDPE) and low-density polyethylene (LDPE) are two main grades, each suitable for different applications. HDPE is used for rigid and durable products, while LDPE is used for more flexible and lightweight applications. Polystyrene (PS), a transparent thermoplastic polymer, is utilized in various consumer goods, packaging, and electronic applications. Known for its excellent dimensional stability and electrical insulation properties, PS is available in crystal and high-impact forms. Crystal PS is used where clarity and transparency are essential, such as food packaging and medical products. High-impact PS, which contains rubber or another elastomer, is used for more durable and impact-resistant applications like toys, automotive components, and electronics. ABS, a thermoplastic polymer, is a versatile material used in automotive parts, toys, electronics, and sporting goods. ABS offers a balance of mechanical, chemical, and thermal properties, making it a popular choice for its high-impact resistance, easy processability, and low cost. Additionally, it is available in various colors and finishes, making it an attractive option for consumer products. These factors contribute to the growth of the plastic segment in the global injection molding machine market during the forecast period.

Carbon is a very popular material in industrial 3D printing due to its ability to enhance materials’ mechanical properties and strength. However, it still suffers from increased porosity and difficult layer adhesion. Therefore, the authors, Qiushi Li, Wei Zhao, Yongxiang Li, Weiwei Yang, and Gong Wang, decided to combine carbon fibers with PEEK and printing the end product within an orthogonal building orientation, and comparing it to the quality of parts made through injection molding.

With the addition of carbon fibers, an increased porosity was observed. The four fracture modes, shown in the picture above, were noted in bending tests with large strain. “The design of a printing route along the stress orientation that cooperates with the incorporation of a reinforced phase into the matrix provides an effective method to enhance the mechanical properties of composites and enlarges the application of 3D printing in lightweight design fields,” concluded the researchers. “This study will be helpful to designers to investigate the influence of microstructures on printed composites during the printing process.”

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly