Thermoset Molding Drives DMP’s Growth in Mexico - thermoset injection molding

Author:gly Date: 2024-09-30

Over the past decade, soft-touch overmolding has radically changed the look, feel, and function of a broad range of consumer products.

To ensure that the TPE melt adequately fills the mold cavity, a key consideration is the ratio between flow length and part thickness. The minimum ratio should be around 150:1. Another proven approach is to locate the gate at the thickest area of the part and to keep flow length as short as possible.

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Mold maintenance is critical, and with this collection of content we’ve bundled some of the very best advice we’ve published on repairing, maintaining, evaluating and even hanging molds on injection molding machines.

Within a few years, however, Stafshede sees sustainability becoming more important to consumers worldwide. He hopes to be using 100% plant-based materials in his full line of kayaks, which would be completely recyclable.

In a few cases (e.g., parts with exceptionally long flow paths or highly wear-prone areas), features are designed into the substrate to create a mechanical interlock after overmolding with TPE.

Our community is about connecting people through open and thoughtful conversations. We want our readers to share their views and exchange ideas and facts in a safe space.

Over the past decade, soft-touch overmolding has radically changed the look, feel, and function of a broad range of consumer products. Abundant new color, texture, and tactile options are available in such products as toothbrushes, razors, power tools, cameras, kitchen items, hand-held electronics, and auto-interior parts.

The aim of this presentation is to guide you through the factors and the numbers that will help you determine if a robot is a smart investment for your application. Agenda: Why are you considering automation? What problems are you trying to solve? How and why automation can help Crunch the numbers and determine the ROI

“At first, we were planning to enter the North American market with our existing portfolio of kayak models, but being there and meeting with customers, dealers, and sales reps, we understood that we needed to have a shorter and wider model to reach a broader target group,” he says.

In the long run, five to 10 years, Melker hopes to set up production in North America with 3D printers alongside traditional manufacturing to enable easy customization, but for now, its best use is for prototypes, says Stafshede.

Mixed in among thought leaders from leading suppliers to injection molders and mold makers at the 2023 Molding and MoldMaking conferences will be molders and toolmakers themselves.

This is illustrated by adhesion data for a 55 Shore A TPE containing a color concentrate and overmolded on a PC/ABS substrate (Fig. 3). In this case, a PP concentrate carrier exhibits adverse effects on adhesion, apparently because of a conflict between the carrier and the TPE. In contrast, data show that with this particular TPE, EVA and TPU carriers provide superior adhesion.

• Gate design: In parts that are subject to high wear during use, and consequently prone to layer delamination, gates should be positioned in the areas that will receive highest wear. That’s because TPEs are hotter (and thus generally adhere better) at the gate rather than at the end of flow. When appearance is a priority, as in cosmetics packaging, gating from the back of the substrate via a pin is preferred since it hides gate blemishes on the TPE.

In this collection, which is part one of a series representing some of John’s finest work, we present you with five articles that we think you will refer to time and again as you look to solve problems, cut cycle times and improve the quality of the parts you mold.

Take a deep dive into all of the various aspects of part quoting to ensure you’ve got all the bases—as in costs—covered before preparing your customer’s quote for services.

Driving this change is the increasingly diverse range of thermoplastic elastomer (TPE) materials. In overmolding, a TPE is injection molded over or around a compatible substrate using either insert or multi-shot processes. The resulting hard-soft structures are quite effective in comfortable, non-slip, and abrasion-resistant handles, grips, and buttons.

Selecting a target melt temperature for the TPE depends on the substrate and the adhesion level required. Most TPE suppliers provide a recommended range of melt temperatures for their products. For maximum adhesion, aim towards the upper end of the supplier’s recommended range.

Gifted with extraordinary technical know how and an authoritative yet plain English writing style, in this collection of articles Fattori offers his insights on a variety of molding-related topics that are bound to make your days on the production floor go a little bit better.

In selecting a gating method, it is advisable to begin with a “steel-safe” design of the gates and to size them initially on the small side, enlarging them later as required. Certain TPEs (like SEBS) require a smaller gate to boost shear and ensure complete mold fill. Other TPEs (TPVs and TPUs) generally require larger-than-normal gates to compensate for their high melt viscosity.

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

• Substrate preparation: Proper preparation and handling of inserts is critical to adhesion performance. The cleaner the insert, the better the bond. The optimal production method is to overmold inserts directly after they are produced, since that minimizes chances of contaminants collecting on the insert surface. If storing inserts is unavoidable, they should be scrupulously protected against dust or dirt. Those who handle inserts should wear gloves, since skin oil can impair adhesion. Also, mold releases are best avoided since they seriously impair bond strength between TPE and substrate.

In this three-part collection, veteran molder and moldmaker Jim Fattori brings to bear his 40+ years of on-the-job experience and provides molders his “from the trenches” perspective on on the why, where and how of venting injection molds. Take the trial-and-error out of the molding venting process.

technotrans says climate protection, energy efficiency and customization will be key discussion topics at PTXPO as it displays its protemp flow 6 ultrasonic eco and the teco cs 90t 9.1 TCUs.

3D printing enables nearly limitless prototypes because it can be done on-site or at a local 3D printing service at a fraction of the cost of traditional manufacturing. Being able to iterate and prototype until your design is just right enables Melker to make a better product, Stafshede adds.

While the melting process does not provide perfect mixing, this study shows that mixing is indeed initiated during melting.

Thanks for reading our community guidelines. Please read the full list of posting rules found in our site's Terms of Service.

Making multiple plastic prototypes sounds like it would have sustainability drawbacks and material waste. Melker, however, 3D prints its prototypes from polymer sourced from off-cast fishing nets that are then infused with wood fiber, a plentiful byproduct of Sweden’s lumber industry. Then, the first prototype is ground up and used as material for the next prototype.

Multiple speakers at Molding 2023 will address the ways simulation can impact material substitution decisions, process profitability and simplification of mold design.

This month’s resin pricing report includes PT’s quarterly check-in on select engineering resins, including nylon 6 and 66.

Rapid prototyping with 3D printing has become relatively standard across industries. It’s cheaper and faster than injection molding and CNC machining, resulting in more efficient product development. Melker took it to the next level to develop a new kayak aimed at the North American market in only six months instead of two years, says company CEO & Creative Director Pelle Stafshede.

• TPE melt temperature: The relationship between temperature of the TPE melt and adhesion strength is reflected in the example of a 65 Shore A TPE overmolded on a PC substrate (Fig. 2). As the melt temperature increases from 370 F to 400 F, a notable improvement in adhesion strength is evident. But a further increase to 430 F actually reduces adhesion strength. In this instance, the optimum melt temperature is somewhat less than 400 F. Molders must balance desired adhesion strength against the possible adverse effects of elevated melt temperature, e.g., thermal degradation and ejection difficulty.

In addition, careful selection of color concentrate carriers is needed to ensure good TPE adhesion to nylons. In general, LDPE and EVA are preferred carriers with nylon substrates.

Preheating inserts prior to overmolding often improves adhesion strength. The extent of improvement depends on the degree of compatibility between insert material and TPE. The appropriate insert temperature depends on the substrate and TPE and is best determined through discussions with the materials suppliers.

Say “manufacturing automation” and thoughts immediately go to the shop floor and specialized production equipment, robotics and material handling systems. But there is another realm of possible automation — the front office.

In order to do so, please follow the posting rules in our site's Terms of Service. We've summarized some of those key rules below. Simply put, keep it civil.

Core Technology Molding turned to Mold-Masters E-Multi auxiliary injection unit to help it win a job and dramatically change its process.

Introduced by Zeiger and Spark Industries at the PTXPO, the nozzle is designed for maximum heat transfer and uniformity with a continuous taper for self cleaning.

This Knowledge Center provides an overview of the considerations needed to understand the purchase, operation, and maintenance of a process cooling system.

Nylon-based materials are an increasingly popular substrate in several high-growth overmolding markets—handles and grips for power and hand tools, appliances, and lawn/garden products. The downside is that nylons are often difficult to overmold with good adhesion. TPEs bond relatively well to unmodified and glass-filled nylons, but fall short when joined to versions that are highly formulated with additive packages.

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Resin drying is a crucial, but often-misunderstood area. This collection includes details on why and what you need to dry, how to specify a dryer, and best practices.

Thousands of people visit our Supplier Guide every day to source equipment and materials. Get in front of them with a free company profile.

Formnext Chicago is an industrial additive manufacturing expo taking place April 8-10, 2025 at McCormick Place in Chicago, Illinois. Formnext Chicago is the second in a series of Formnext events in the U.S. being produced by Mesago Messe Frankfurt, AMT – The Association For Manufacturing Technology, and Gardner Business Media (our publisher).

In a time where sustainability is no longer just a buzzword, the food and beverage packaging industry is required to be at the forefront of this innovation. By adopting circular packaging processes and solutions, producers can meet regulatory requirements while also satisfying consumer demand and enhancing brand reputation. Join Husky to learn more about the broader implications of the circular economy — as well as how leading brands are leveraging this opportunity to reduce costs, increase design flexibility and boost product differentiation. Agenda: The cost and operational benefits of embracing circularity Key materials in circular packaging — including rPET and emerging bioplastics How to design a circular food and beverage package Strategies for selecting sustainable closures to future-proof packaging solutions Optimization and streamlining of production processes for enhanced efficiency How Husky Technologies can enable your sustainable success

Melker of Sweden was founded with the ambition to make the outdoor hardware industry more sustainable. Even the final Melker kayaks are made with injection molding of mostly bio-based material with natural flax fibers and cork. It’s a sustainable approach that’s part of the Swedish identity, but not that top-of-mind for Americans, Stafshede says.

Back in Sweden from their North American market research, Melker designers got busy drafting the new more recreational kayak called the Värmdö. It’s wider, shorter, and more lightweight than the company's Swedish-style sea kayaks. It’s also more comfortable, with extra padding and a more customizable-fit cockpit. There are no cup holders, but Stafshede says it was discussed.

Additional considerations also make nylon adhesion more difficult. One is their propensity for high moisture pick-up, which makes careful drying imperative. And the melt temperatures of nylons are higher than for most other substrates, so the TPE melt temperature has to be increased accordingly to ensure good bonding. Preheating of nylon inserts is also generally advised.

Multi-shot molding requires a special press with multiple barrels that allow several materials to be shot into the same mold. (Most often, such parts use two-shot molding, but some parts require three or four shots.) Benefits are reduced overall production time, superior part quality, and lower labor requirements. The approach is economically viable in programs of 250,000 parts/yr or more and regions where labor costs are high.

Another problem is the broad array of available nylons, which differ by resin class (e.g., nylon 6, 66, and 12), reinforcement type and loading, and additives used. In the case of a first-generation TPE, test data show that a dramatic loss of adhesion strength occurs when it is bonded to impact-modified and heat-stabilized nylon 6 (Fig. 4). But progress is being made: Data show that a second-generation, improved-adhesion grade of the same TPE class yields significantly improved adhesion performance, even with heat-stabilized products.

Discover how artifical intelligence is revolutionizing plastics processing. Hear from industry experts on the future impact of AI on your operations and envision a fully interconnected plant.

In this collection of content, we provide expert advice on welding from some of the leading authorities in the field, with tips on such matters as controls, as well as insights on how to solve common problems in welding.

Scientists use the Otter Box to gather data in demanding outdoor environments. The soft TPE’s roles are to provide a waterproof seal, impart a grippy feel, and adhere strongly to the PC-ABS substrate.

Mike Sepe has authored more than 25 ANTEC papers and more than 250 articles illustrating the importance of this interdisciplanary approach. In this collection, we present some of his best work during the years he has been contributing for Plastics Technology Magazine.

The best way to reach the optimal TPE melt temperature is to approach it gradually, not necessarily by increasing barrel temperature, but via higher screw rpm or injection speed. A problem in determining the actual melt temperature is that it is not always equivalent to injection nozzle temperature. A sensible approach is to use a pyrometer to measure melt temperature of a TPE air shot.

In both processes, strength and durability of adhesion between TPE and substrate require compatible hard and soft materials. The type of overmolding method used also affects adhesion performance: Multi-shot molding, by bringing together several melt fronts, generally offers superior adhesion. Adhesion performance is also affected by a number of additional factors:

Join KraussMaffei for an insightful webinar designed for industry professionals, engineers and anyone interested in the manufacturing processes of PVC pipes. This session will provide a comprehensive understanding of the technology behind the production of high-quality PVC pipes: from raw material preparation to final product testing. Agenda: Introduction to PVC extrusion: overview of the basic principles of PVC pipe extrusion — including the process of melting and shaping PVC resin into pipe forms Equipment and machinery: detailed explanation of the key equipment involved — such as extruders, dies and cooling systems — and their roles in the extrusion process Process parameters: insight into the critical process parameters like temperature, pressure and cooling rates that influence the quality and consistency of the final PVC pipes Energy efficiency: examination of ways to save material and energy use when extruding PVC pipe products

• Shut-off design: Design of the transition, or shut-off, area between the TPE and substrate is critical to adhesion. Designs should avoid “feathering,” or gradual thinning of the overmolded TPE. Thin layers cause inadequate bonding and can result in curling or fraying of the TPE layer at the tapered edges (see Fig. 1A).

While the major correction in PP prices was finally underway, generally stable pricing was anticipated for the other four commodity resins.

“We see our innovation, design, research, and development as a long-term investment for our company, coming generations, and the great outdoors,” Stafshede says of his company’s philosophy. “Making the best products is crucial for saving the planet.”

A critical challenge for designers and producers of these parts is poor adhesion of TPE to substrate, which reveals itself in peeling, curling, fraying, or delamination of the material layers. Initially, this was a fairly straightforward issue since the most common approach was to combine an olefin-based TPE with a compatible rigid PP substrate.

One solution is to incorporate a “step” in the substrate profile to create an abrupt transition between TPE and substrate (Fig. 1B). Alternatively, the substrate might include an indentation, with the shut-off designed to put the TPE flush against the substrate (Fig. 1C). Both approaches reduce feathering, neutralize curling, and eliminate tear points that might initiate fraying.

Since prying fingers tend to challenge adhesion in soft-touch infant products, molding technique and tool design are especially critical.

Exhibitors and presenters at the plastics show emphasized 3D printing as a complement and aid to more traditional production processes.

August 29-30 in Minneapolis all things injection molding and moldmaking will be happening at the Hyatt Regency — check out who’s speaking on what topics today.

Plastics Technology’s Tech Days is back! Every Tuesday in October, a series of five online presentations will be given by industry supplier around the following topics: Injection Molding — New Technologies, Efficiencies Film Extrusion — New Technologies, Efficiencies Upstream/Downstream Operations Injection Molding — Sustainability Extrusion — Compounding Coming out of NPE2024, PT identified a variety of topics, technologies and trends that are driving and shaping the evolution of plastic products manufacturing — from recycling/recyclability and energy optimization to AI-based process control and automation implementation. PT Tech Days is designed to provide a robust, curated, accessible platform through which plastics professionals can explore these trends, have direct access to subject-matter experts and develop strategies for applying solutions in their operations.

Join this webinar to explore the transformative benefits of retrofitting your existing injection molding machines (IMMs). Engel will guide you through upgrading your equipment to enhance monitoring, control and adaptability — all while integrating digital technologies. You'll learn about the latest trends in IMM retrofitting (including Euromap interfaces and plasticizing retrofits) and discover how to future-proof your machines for a competitive edge. With insights from industry experts, it'll walk you through the decision-making process, ensuring you make informed choices that drive your business forward. Agenda: Maximize the value of your current IMMs through strategic retrofitting Learn how to integrate digital technologies to enhance monitoring and control Explore the benefits of Euromap interfaces and plasticizing retrofits Understand how retrofitting can help meet new product demands and improve adaptability Discover how Engel can support your retrofitting needs, from free consultations to execution

Across the show, sustainability ruled in new materials technology, from polyolefins and engineering resins to biobased materials.

Prototypes are how companies measure if a new product will sink or swim. At Melker of Sweden, a sport kayak maker, they take this product development stage quite literally — 3D printing full-size prototype kayaks in one piece to field test on the water.

The 3D printing technology behind the prototypes that made the Värmdö possible is very similar to the desktop version hobbyists use to churn out figurines and lampshades but on a much larger scale. Called robotic arm additive manufacturing, melted plastic is extruded layer by layer through a nozzle at the end of a robotic arm, fed by a hopper full of material. The robotic arm follows the path determined by the digital file.

In this collection of articles, two of the industry’s foremost authorities on screw design — Jim Frankand and Mark Spalding — offer their sage advice on screw design...what works, what doesn’t, and what to look for when things start going wrong.

“When the technology and the materials mature, [3D printing] is definitely going to be a very good way of producing kayaks because then you can have local production and mass customization,” says Stafshede. Melker achieved a company milestone in 2023 by bringing all manufacturing to Sweden.

Additive technology creates air pockets in film during orientation, cutting down on the amount of resin needed while boosting opacity, mechanical properties and recyclability.

Despite price increase nominations going into second quarter, it appeared there was potential for generally flat pricing with the exception of a major downward correction for PP.

The Plastics Industry Association (PLASTICS) has released final figures for NPE2024: The Plastics Show (May 6-10; Orlando) that officially make it the largest ever NPE in several key metrics.

• Predrying: Some TPE types—including TPU, TPV, and copolyesters—tend to be hygroscopic, or prone to moisture pick-up. If not appropriately dried prior to molding, absorbed moisture can turn to steam and harm adhesion at the interface of the two materials. Moisture also can hydrolyze some resins, harm surface properties, and increase ejection difficulty. Moisture at the time of molding generally should not exceed 0.05% by volume. Common practice is to dry TPEs in a desiccant dryer with a –40 F dewpoint.

North America is the largest kayak market in the world with expected 3.6% annual growth over the next 10 years fueled by a rising emphasis on adventure sports and the popularity of water sports, particularly kayaking competitions, according to Transparency Market Research.

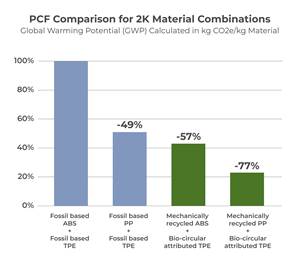

Swedish compounders HEXPOL TPE AB and Polykemi AB have collaborated on a 2K sustainable development project for consumer products.

Across all process types, sustainability was a big theme at NPE2024. But there was plenty to see in automation and artificial intelligence as well.

Ultradent's entry of its Umbrella cheek retractor took home the awards for Technical Sophistication and Achievement in Economics and Efficiency at PTXPO.

Adhesion is not the only important consideration in overmolding, so here is some advice on aspects of tool design that will optimize other areas of performance:

After successfully introducing a combined conference for moldmakers and injection molders in 2022, Plastics Technology and MoldMaking Technology are once again joining forces for a tooling/molding two-for-one.

Melker does not own its own 3D printers yet, instead working with the Research Institute of Sweden (RISE), which is partly government-funded. RISE gives companies like Melker access to high-tech equipment and the engineers that run it but Melker also pays for the access. Even without government funding, Stafshede says, the 3D-printed prototypes are affordable at a fraction of the cost of traditional ones.

Successfully starting or restarting an injection molding machine is less about ticking boxes on a rote checklist and more about individually assessing each processing scenario and its unique variables.

Plastics Technology covers technical and business Information for Plastics Processors in Injection Molding, Extrusion, Blow Molding, Plastic Additives, Compounding, Plastic Materials, and Resin Pricing. About Us

In insert molding, the rigid substrate is molded first and transferred to a second mold, where a TPE is shot around the insert to create the finished part. The process uses standard injection molding machines and relatively simple, low-cost tools. Insert molding is best suited to applications involving relatively low volumes and manufacturing locations where labor costs are low.

Processors with sustainability goals or mandates have a number of ways to reach their goals. Biopolymers are among them.

“There are so many bad products in the world because companies can’t afford just that one more prototype that would have made it perfect,” says Stafshede. “People say, ‘We wish we could have lowered that or made that bigger, but we need to live with this.’ ”

While prices moved up for three of the five commodity resins, there was potential for a flat trajectory for the rest of the third quarter.

Developing a completely new product would have put Melker’s expansion plans back years. The traditional way of developing a kayak goes from computer design to creating an expensive metal mold ($5,000 to $10,000) into which plastic is injected to form the first prototype. Changes require more molds and more prototypes, taking time and material, plus creating plastic waste.

Where the TPE layer is less than 0.060 in. thick, the feel of a soft elastomer can easily be negated by the hardness of the underlying substrate. The degree of cushioning provided by a TPE layer is also greatly influenced by the substrate’s inherent hardness.

Large-scale 3D printing is not widely available as a service from 3D printing companies — although its growing — and only a handful of companies make the equipment. The extruder heads, available from U.S.-based Massive Dimension or Canadian Dyze Design fit onto standard robotic arms, such as from Kuka or ABB. Full turnkey systems are available from 3D printer makers, such as Caracol and CEAD. The controlling software comes from the robotic arm makers or more specialized 3D-printing-focused companies, such as start-ups Ai Build and Adaxis.

While prices moved up for three of the five commodity resins, there was potential for a flat trajectory for the rest of the third quarter.

• Concentrate carrier compatibility: Overmolding with TPEs containing color concentrates can be tricky, one danger being conflict between the colorant carrier and the TPE. The workhorse carrier for TPEs has long been PP, but this carrier frequently performs poorly when bonding certain TPE families to nylon, PC/ABS, and other engineered substrates.

Crisp finish lines between the opaque TPE skin and clear PC substrate are essential in this computer lap station, both for appearance and strong adhesion.

Learn about sustainable scrap reprocessing—this resource offers a deep dive into everything from granulator types and options, to service tips, videos and technical articles.

• Surface texture: Designers are sometimes tempted to underscore the texture and grip properties of a TPE by polishing the mold to add a smooth finish. Yet a smooth finish sometimes actually highlights flaws like knit lines and blemishes in the part. Conversely, texturing of part surfaces is often effective in hiding flaws and imparting a “grippy” or leather-like feel. Certain textures have the effect of imparting a harder or softer feel than might be anticipated in light of the TPE’s Shore A durometer. The goal is to balance the surface texture and durometer values of the TPE to get the intended product feel.

In recent years, however, the range of materials used in overmolding has expanded significantly to include more TPE classes (e.g, TPU, TPV, SEBS) and a broader range of substrates (ABS, PC, and nylon). While the broader materials spectrum for overmolding expands opportunities for soft-touch design, it also adds new levels of complexity and poses new challenges in adhesion.

NPE2024: Coinjection of postconsumer resin, in-mold decoration, LSR micromolding and bioplastics processing are just some of the machine displays at Milacron's booth.

Sustainability continues to dominate new additives technology, but upping performance is also evident. Most of the new additives have been targeted to commodity resins and particularly polyolefins.

Join Wittmann for an engaging webinar on the transformative impact of manufacturing execution systems (MES) in the plastic injection molding industry. Discover how MES enhances production efficiency, quality control and real-time monitoring while also reducing downtime. It will explore the integration of MES with existing systems, emphasizing compliance and traceability for automotive and medical sectors. Learn about the latest advancements in IoT and AI technologies and how they drive innovation and continuous improvement in MES. Agenda: Overview of MES benefits What is MES? Definition, role and brief history Historical perspective and evolution Longevity and analytics Connectivity: importance, standards and integration Advantages of MES: efficiency, real-time data, traceability and cost savings Emerging technologies: IoT and AI in MES

Moreover, thickness of the TPE layer also affects adhesion strength. Thin TPE layers tend to surrender heat rapidly in the cold cavity, and the drop in temperature tends to reduce bonding strength. The challenge for the designer is to strike a balance between the durometer and thickness of the TPE to achieve the cushioning level desired.

Second quarter started with price hikes in PE and the four volume engineering resins, but relatively stable pricing was largely expected by the quarter’s end.

“There’s definitely a different mindset in America. Sales reps and customers are interested enough to listen, but there’s a reluctance to pay more for a boat being produced in a more sustainable manner.”

Setting the Melker brand apart from the competition in the North American market, Stafshede believes, will be its design, sustainability story, and the fact that the Värmdö is made to last a lifetime.

The best antidote is a shut-off design that creates a sharp transition between TPE and substrate. Ideally, a uniform TPE layer thickness of around 0.04 in. is desirable for good adhesion, but that is not always feasible.

Join Engel in exploring the future of battery molding technology. Discover advancements in thermoplastic composites for battery housings, innovative automation solutions and the latest in large-tonnage equipment designed for e-mobility — all with a focus on cost-efficient solutions. Agenda: Learn about cutting-edge thermoplastic composites for durable, sustainable and cost-efficient battery housings Explore advanced automation concepts for efficient and scalable production See the latest large-tonnage equipment and technology innovations for e-mobility solutions

• Ejection efficiency: Part ejection can be facilitated by designing 0.5° to 1° of draft into each side of the mold. With more ejection-resistant materials like TPUs, a 5° to 6° draft is sometimes required. Texturing the tool surface frequently improves ejection, whereas a more polished surface tends to impair it.

When, how, what and why to automate — leading robotics suppliers and forward-thinking moldmakers will share their insights on automating manufacturing at collocated event.

• Vent design: Air entrapment in the cavity during TPE overmolding is also detrimental to adhesion and is best addressed by adequate venting in the tool. Insufficient venting can show up as poor adhesion at the end-of-flow points, scorching of the TPE, or even short shots. Typical vent depths are between 0.0005 and 0.001 in. The right vent depth for a given part depends partly on the flow properties of the TPE involved.

• “Feel” versus thickness: The tactile feel of an overmolded part is the sum of several factors, just one being the inherent softness (Shore A durometer) of the TPE. Part feel also depends on the TPE’s coefficient of friction, texture, and—most notably—wall thickness.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly