The many ways to manufacture a part - plastic mold fabrication

Author:gly Date: 2024-09-30

Thorsten Häuser, development manager, explains: “We developed our TOP 700 dosing pump to meet customer demand for a space- and material-saving solution from ELMET. We’ve achieved this with a footprint of less than 0.5 m² (799 mm × 600 mm) and our new pump design. As a result, this new dosing system is particularly suitable not only for customers processing high-value, shear-sensitive or abrasive materials but also for R&D, prototyping and small-batch applications. The TOP 700 rounds out our product range while setting new standards in compact dosing technology.”

It was reported that new materials R&D for MIM was focused on nickel free alloys, non-magnetic titanium and aluminium alloys. Applications for these materials were found mainly in the automotive and medical industries, including for renewable energy vehicles and medical implants, and in the aerospace and specialist hardware industries.

The major driving force for growth in China’s MIM industry continues to be consumer electronics applications, with the largest application area being mobile phones (65.7%), followed by wearable devices (6.9%) and computers (4.9%). Other application areas for MIM include automotive (7.2%), hardware (6%) and medical devices (3.9%).

TOP 700 provides the same high precision dosing of silicones and additives as Elmet’s flagship TOP 7000 Pro dosing system with its 200 or 20 litre drum size which was launched back in 2021.

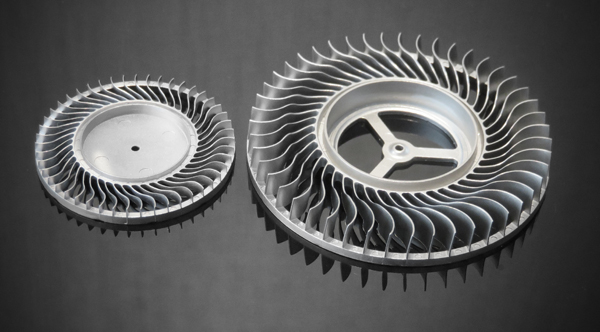

These MIM CPU fans highlight the evolving capabilities of Metal Injection Moulding in China (Courtesy Shenzhen Shindy Technology Co., Ltd, China)

The 2017 China Metal Injection Moulding Industry Status Report, published by the Powder Metallurgy Branch Association of the China Steel Construction Society, provides invaluable insight into the recent development of China’s Metal Injection Moulding industry.

Reach a truly international audience that includes component manufacturers, end-users, industry suppliers, analysts, researchers and more.

Designed to be FDA- and EMA-compliant, the new TOP 700 dosing system is used for applications requiring the highest levels of cleanliness such as medical technology, personal care, foodstuffs and optics. Virtually abrasion-free pumping also prevents metal particle contamination of the LSR which would impair its functionality. There are also no limits to the consistency of the processed LSR under real-world conditions because Elmet’s new system can dose any commercially available product with the same precision thanks to its ability to handle viscosities of between 0.001 Pas and 2000 Pas (shear rate 10/s) or 16,000 Pas (1/s). Its optionally OPC UA- and Euromap 82.3-compliant control system can be seamlessly integrated into the injection moulding machine’s own control system.

Don't miss any new issue of PIM International, and stay up to date with the latest industry news. Sign up to our fortnightly newsletter.

The total shipment of materials (powders and feedstock) for MetaI Injection Moulding was reported at between 8000–8500 tons. The report stated that market share remains relatively equally divided between domestic (55%) and foreign (45%) producers. It was estimated in the report that around 80% of Chinese MIM firms have the capability to produce feedstock in house, although many use a combination of ready to use and self manufactured feedstocks. Of imported feedstock, BASF’s Catamold is reported to have accounted for 90% of the market.

Sales of MIM parts were reported to be in the region of CNY ¥5.4 billion ($788 million) in 2017, an increase of 10–15% compared to 2016. At present, there are said to be over 250 MIM manufacturers in China.

Extensive MIM, CIM industry and sinter-based AM industry news, plus the following exclusive deep-dive articles and reports:

The most widely used MIM materials in China continued to be stainless steels (70%) and low alloy steel (20%), accounting for a combined 90% of production. Tungsten-based materials accounted for 8% of production, with hardmetals and copper, titanium and aluminium alloys making up the remaining 2%.

To avoid operating errors, the drums can be changed fully automatically from the drum rim from three sides within two minutes. Intuitive operation of the system, the use of simple clamp connections, a guided drum change procedure and an integrated cooling system mean even relatively low-skilled personnel can operate it without any problem. Fully automatic venting as standard completes the system’s many and varied safety and convenience features.

The TOP 700 can achieve delivery rates of over five litres/minute at a maximum pump pressure of 210 bar, so enabling short cycle times both when filling larger parts and with large numbers of small cavities. Additives and colours can be dispensed from 1, 4 and 20 litre containers. In order to achieve the dosing precision that is particularly vital for very small parts, the volumetric meter for colours has a resolution of below 0.1 μl/l. Depending on requirements, dosing can be carried out simultaneously or in a freely selectable mixing ratio.

The report anticipates that, with the continued involvement of investors, as well as moves by some Chinese-based MIM enterprises toward stronger integration and overseas development, the pace of growth for the industry will quicken. Meanwhile, innovative small and medium-scale enterprises will continue to have the space to grow and develop as the industry evolves.

The free-to-access PIM International magazine archive offers unparalleled insight into the world of MIM, CIM and sinter-based AM from a commercial and technological perspective through:

Due to the optimised design of the follower plates, just 40 ml of residues are left behind when the 20 litre drums have to be changed, resulting in material utilisation of up to 99.8%. With a design service life of 20 years or more for all its mechanical components, a modular structure and particular ease of servicing which keeps maintenance costs low, the TOP 700 is synonymous with cost-efficiency. Its low energy consumption of less than 50 Wh and minimal compressed air consumption also help to keep costs down.

Discover suppliers of these and more in our advertisers’ index and buyer’s guide, available in the back of PIM International.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly