The Best Metal 3D Printers in 2024 - affordable injection molding

Author:gly Date: 2024-09-30

The free-to-access PIM International magazine archive offers unparalleled insight into the world of MIM, CIM and sinter-based AM from a commercial and technological perspective through:

While prices moved up for three of the five commodity resins, there was potential for a flat trajectory for the rest of the third quarter.

What is not fully apparent in these charts is the growing value of the aerospace industry for MIM in Europe. As reported in PIM International, Vol. 13 No. 3, September 2019, Schunk Sintermetalltechnik GmbH is one example of a European MIM producer that has found success in manufacturing a new generation of high-performance MIM components that are now flying in Rolls-Royce aero engines, with an example being IN713LC superalloy stator vanes (Fig. 5). Alliance-MIM, a French MIM producer, is also reporting success in this area, with rotating MIM aero engine parts accounting for 25% of its MIM sales.

In terms of MIM feedstock developments, BASF SE, Ludwigshafen, Germany, promoted its new Catamold® THOR feedstock at World PM2022; a maraging ultra-high strength steel suited for parts that require the combination of strength and ductility/toughness. Target applications include MIM hinges and other high-performance structural applications. MIM hinges are seeing widespread adoption in the consumer electronics industry, in particular for laptops and folding smartphones, where the unique combination of component complexity, high production volumes and demanding tolerances play into MIM technology’s strengths.

While prices moved up for three of the five commodity resins, there was potential for a flat trajectory for the rest of the third quarter.

The global MIM industry is in a strong position for continued growth. Whilst there is inevitably uncertainty due in large part as a result of war in Ukraine companies around the world are investing in production capacity. The most recent EPMA survey of MIM producers, the results of which are confidential but were presented during the EuroMIM meeting at World PM2022, provided evidence of investment in the European MIM industry to increase sintering capacity and for new injection moulding equipment.

Plastics Technology covers technical and business Information for Plastics Processors in Injection Molding, Extrusion, Blow Molding, Plastic Additives, Compounding, Plastic Materials, and Resin Pricing. About Us

In this collection of articles, two of the industry’s foremost authorities on screw design — Jim Frankand and Mark Spalding — offer their sage advice on screw design...what works, what doesn’t, and what to look for when things start going wrong.

Take a deep dive into all of the various aspects of part quoting to ensure you’ve got all the bases—as in costs—covered before preparing your customer’s quote for services.

In this collection, which is part one of a series representing some of John’s finest work, we present you with five articles that we think you will refer to time and again as you look to solve problems, cut cycle times and improve the quality of the parts you mold.

Discover suppliers of these and more in our advertisers’ index and buyer’s guide, available in the back of PIM International.

Say “manufacturing automation” and thoughts immediately go to the shop floor and specialized production equipment, robotics and material handling systems. But there is another realm of possible automation — the front office.

This Knowledge Center provides an overview of the considerations needed to understand the purchase, operation, and maintenance of a process cooling system.

Over the last decade, the Metal Injection Molding industry enjoyed dramatic growth on the back of the rise of applications in smartphones. There ar...»

It was reported by Chu that the majority of MIM parts produced in Taiwan were also consumed by the consumer electronics sector (60%), while 17% went to transportation, 16% to industrial and 7% to other sectors.

Putting European MIM into context in his World PM2022 plenary presentation, Ralf Carlström, EPMA president, stated that the value of MIM parts accounted for 4% of PM-related parts production in Europe in 2021 by sales. The most valuable PM product segment was hard materials, accounting for 30% of the total market value of PM parts due to the high price of raw materials, followed by PM structural parts/bearings at 25%, diamond tools at 16%, sintered magnets (12%), PM semi parts (8%), HIP parts (3%) and AM parts (2%). However, the growth in value of MIM part sales in 2021, at 22% over 2020, outstripped PM structural parts production (11.4%), HIP (20%), and AM (15%) in 2021.

In this collection of content, we provide expert advice on welding from some of the leading authorities in the field, with tips on such matters as controls, as well as insights on how to solve common problems in welding.

Extensive MIM, CIM industry and sinter-based AM industry news, plus the following exclusive deep-dive articles and reports:

Neste RE consists of pure hydrocarbons made from bio-based raw materials and can be used as a drop-in solution to replace fossil feedstock in the making of polymers and chemicals. Photo Credit: Neste

Ahead of arriving at the congress, and in light of a global economy rocked by COVID and, later, Russia’s invasion of Ukraine, I had limited expectations about how upbeat conversations with MIM producers would be, and what industry statistics would reveal. Once on site, however, it became clear that the MIM industry had not only bounced back from the hit to production that COVID triggered in 2020, but that it was thriving.

Join Wittmann for an engaging webinar on the transformative impact of manufacturing execution systems (MES) in the plastic injection molding industry. Discover how MES enhances production efficiency, quality control and real-time monitoring while also reducing downtime. It will explore the integration of MES with existing systems, emphasizing compliance and traceability for automotive and medical sectors. Learn about the latest advancements in IoT and AI technologies and how they drive innovation and continuous improvement in MES. Agenda: Overview of MES benefits What is MES? Definition, role and brief history Historical perspective and evolution Longevity and analytics Connectivity: importance, standards and integration Advantages of MES: efficiency, real-time data, traceability and cost savings Emerging technologies: IoT and AI in MES

Davies also explained that purchasing trends for metal powders have also changed since the pandemic, with customers looking to secure longer term contracts for stability of metal powder supply. MIM powder sales, he stated, continue to be dominated by stainless steels, in particular 316L and 17-4 PH.

Ultradent's entry of its Umbrella cheek retractor took home the awards for Technical Sophistication and Achievement in Economics and Efficiency at PTXPO.

This is especially the case for electric vehicles, where entirely new vehicle platforms offer the chance to design for MIM from the start, reducing part weight, increasing functionality and complexity, and potentially combining what would have been multiple components into one. Other sources also confirmed that Tier 1 and Tier 2 suppliers are taking a serious look at MIM for numerous new applications, again primarily for next-generation automotive applications.Of course, the hard reality of the past two years is that, whilst potential new applications exist, those MIM producers most closely tied to the automotive industry faced the biggest challenges as COVID and the supply chain crisis impacted automotive production. But the above reports bode well for the future of a sector that is crucial for the European MIM industry.

After successfully introducing a combined conference for moldmakers and injection molders in 2022, Plastics Technology and MoldMaking Technology are once again joining forces for a tooling/molding two-for-one.

Join KraussMaffei for an insightful webinar designed for industry professionals, engineers and anyone interested in the manufacturing processes of PVC pipes. This session will provide a comprehensive understanding of the technology behind the production of high-quality PVC pipes: from raw material preparation to final product testing. Agenda: Introduction to PVC extrusion: overview of the basic principles of PVC pipe extrusion — including the process of melting and shaping PVC resin into pipe forms Equipment and machinery: detailed explanation of the key equipment involved — such as extruders, dies and cooling systems — and their roles in the extrusion process Process parameters: insight into the critical process parameters like temperature, pressure and cooling rates that influence the quality and consistency of the final PVC pipes Energy efficiency: examination of ways to save material and energy use when extruding PVC pipe products

Resin drying is a crucial, but often-misunderstood area. This collection includes details on why and what you need to dry, how to specify a dryer, and best practices.

August 29-30 in Minneapolis all things injection molding and moldmaking will be happening at the Hyatt Regency — check out who’s speaking on what topics today.

Trexel and Husky are cooperating on molding recyclable opaque white preforms for PET bottles, which provide a light barrier using foam instead of pigment.

Formnext Chicago is an industrial additive manufacturing expo taking place April 8-10, 2025 at McCormick Place in Chicago, Illinois. Formnext Chicago is the second in a series of Formnext events in the U.S. being produced by Mesago Messe Frankfurt, AMT – The Association For Manufacturing Technology, and Gardner Business Media (our publisher).

In terms of material usage, stainless steels accounted for 74.4% of production (previous year: 73.2%). Stainless steels, Fe-Ni materials and magnetic materials accounted for over 85% of production. The value of stainless steel MIM parts sales in 2021 was stated as JPY 10,193 million, a 36.4% increase from the previous year. Fig. 10 shows a detailed breakdown of MIM materials usage in Japan in 2021.

There are multiple reasons for such a positive current position. One European industry professional explained that it had been a “remarkable year” for MIM in the region, with new entrants in the market, but more importantly, with MIM “enjoying increased recognition in the automotive sector as a new generation of vehicles are designed and parts are becoming ever more complex.”

Around half of global MIM production, about $1.5 billion, comes from China and Taiwan, with the latter accounting for around $300 million of sales.

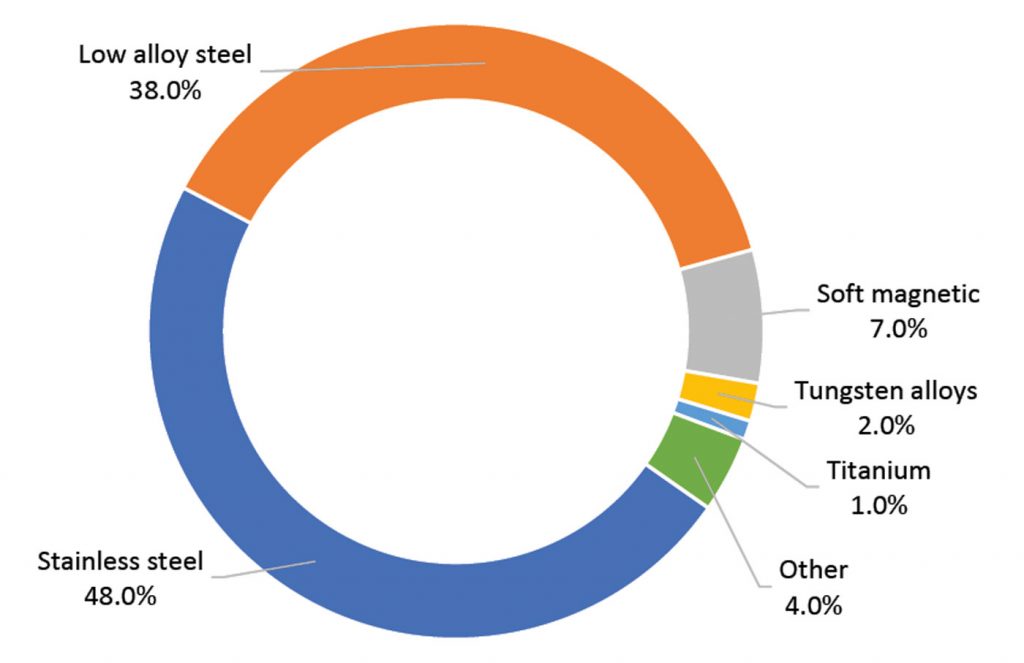

Total 2021 North American metal powder shipments to the MIM and AM industries increased by an estimated 5–10% to between 3,934,767 and 4,202,178 kg. Of this amount, an estimated 360,000 kg is dedicated to AM. MIM and AM powder producers were reported to be seeing strong demands for materials. Generally, the materials of choice are stainless and low-alloy steels, but there is considerable developmental work being performed on aluminium, titanium, and an array of other metal powders and alloys. Fig. 13 gives a breakdown of North American MIM materials usage.

Across all process types, sustainability was a big theme at NPE2024. But there was plenty to see in automation and artificial intelligence as well.

Sustainability continues to dominate new additives technology, but upping performance is also evident. Most of the new additives have been targeted to commodity resins and particularly polyolefins.

Mike Sepe has authored more than 25 ANTEC papers and more than 250 articles illustrating the importance of this interdisciplanary approach. In this collection, we present some of his best work during the years he has been contributing for Plastics Technology Magazine.

Neste RE is Neste’s feedstock for polymers production, made 100% from bio-based raw materials such as waste and residues, e.g. used cooking oil, to replace fossil feedstock in the value chain. Japanese beverage company Suntory will utilize the renewable PET resin to produce bottles for its products in 2024.

Powder prices continue to be a concern for the MIM industry, with the gains brought by a more competitive marketplace offset by higher raw material costs, higher energy prices and the high costs of the gases used during atomisation.

Across the show, sustainability ruled in new materials technology, from polyolefins and engineering resins to biobased materials.

While the major correction in PP prices was finally underway, generally stable pricing was anticipated for the other four commodity resins.

Exhibitors and presenters at the plastics show emphasized 3D printing as a complement and aid to more traditional production processes.

Mold maintenance is critical, and with this collection of content we’ve bundled some of the very best advice we’ve published on repairing, maintaining, evaluating and even hanging molds on injection molding machines.

A picture of MIM in Asia was presented by Chiu-Lung Chu, president of the Asian Powder Metallurgy Association (APMA). The APMA is made up of the Japan Powder Metallurgy Association (JPMA), Japan Society of Powder and Powder Metallurgy (JSPM), Korean Powder Metallurgy Association (KPMA), Korean Powder Metallurgy & Materials Institute (KPMI), Taiwan Powder Metallurgy Association (TPMA), China Powder Metallurgy Alliance (CPMA), China Powder Metallurgy Society, Powder Metallurgy Association of India (PMAI), and Thailand Powder Metallurgy Association (ThaiPMA). The statistics presented in Chu’s overview were provided, separately, by these associations.

Within Europe, a key market for parts made by MIM and Ceramic Injection Moulding is luxury products – including components for high-end watches and leather goods. “Right now, people are buying luxe, and demand for PIM parts is extraordinary,” stated one producer.

Processors with sustainability goals or mandates have a number of ways to reach their goals. Biopolymers are among them.

Don't miss any new issue of PIM International, and stay up to date with the latest industry news. Sign up to our fortnightly newsletter.

Type 420 martensitic stainless steel covers a wide carbon range of 0.15% to 0.45%. Demand for this material from the 3C, automotive, biomedical and...»

The PM World Congress series has, for many years, presented a rare opportunity to speak face to face with a significant number of Metal Injection Moulding industry suppliers and part producers from around the world, to get a feel for the direction the industry is going in, and to understand the opportunities that companies are seeing as well as the challenges that they are facing. Combined with some usually hard to come by data from the congress’s ‘State of the PM Industry’ presentations from different world regions, combined with insight from Special Interest Seminars, a picture can emerge of the health and prosperity of the MIM industry.

Fig. 2 shows that MIM sales in Europe bounced back in 2021 from a COVID-related dip, showing a sales increase of 22% from 2020 and breaking the €500 million mark for the first time in the technology’s history. Expectation is that 2022 will show continued growth on 2021.

Plastics Technology’s Tech Days is back! Every Tuesday in October, a series of five online presentations will be given by industry supplier around the following topics: Injection Molding — New Technologies, Efficiencies Film Extrusion — New Technologies, Efficiencies Upstream/Downstream Operations Injection Molding — Sustainability Extrusion — Compounding Coming out of NPE2024, PT identified a variety of topics, technologies and trends that are driving and shaping the evolution of plastic products manufacturing — from recycling/recyclability and energy optimization to AI-based process control and automation implementation. PT Tech Days is designed to provide a robust, curated, accessible platform through which plastics professionals can explore these trends, have direct access to subject-matter experts and develop strategies for applying solutions in their operations.

Additive technology creates air pockets in film during orientation, cutting down on the amount of resin needed while boosting opacity, mechanical properties and recyclability.

With sustainability top-of-mind in the plastics industry, this was a ground-breaking show for builders of recycling equipment. It also prompted new thinking in thinwall injection molding.

Gifted with extraordinary technical know how and an authoritative yet plain English writing style, in this collection of articles Fattori offers his insights on a variety of molding-related topics that are bound to make your days on the production floor go a little bit better.

There were also indications at World PM2022 that new entrants to the MIM feedstock market are on the horizon, including from companies based in Europe and Asia.

Learn about sustainable scrap reprocessing—this resource offers a deep dive into everything from granulator types and options, to service tips, videos and technical articles.

What could be interpreted as an increasing interest in MIM from the automotive industry coincides with increased confidence of MIM producers in their own process capabilities. One European MIM producer explained that, in recent years, it has been able to successfully produce complex parts in high volumes that not so long ago would have been regarded as too challenging – thanks to advances in the quality and capability of MIM feedstocks, processing technology and simulation software.

During his presentation on the European MIM industry in the World PM2022 Special Interest Seminar on Global MIM markets, comments by Paul Davies, Sandvik, UK, a leading supplier of gas atomised MIM-grade powders, mirrored the market data presented in terms of a global COVID-related dip in MIM production. He stated, however, that MIM powder shipments to Asia from Sandvik had reduced the most in 2020 and 2021 – during the COVID period – compared to the other regions. He added that, whilst Europe had benefitted with an increased share of MIM powder shipments, North America also rebounded strongly, with MIM powder shipments now levelling off to pre-pandemic levels.

The most comprehensive information on MIM in Japan was presented by Kenji Doi, Osaka Yakin Kogyo Co., Ltd, Japan, in a World PM 2022 Special Interest Seminar. His reporting was largely based on the JPMA’s 2021 Report for MIM Market. Doi stated that annual total MIM sales in Japan in 2021 were JPY 13.69 billion (approx $100 million) and he stated that sales volume had increased over the previous year (Fig. 8). The JPMA collects what are believed to be the most detailed MIM industry statistics available, generated each year through a questionnaire sent to nineteen companies, including members and non-members. 2021’s figures are from data provided by all nineteen companies.

Metal Powder Industries Federation (MPIF) President Rodney Brennen gave delegates a detailed overview of the state of the North American Powder Metallurgy industry during the World PM2022 plenary session. The North American Powder Metallurgy industry, he reported, had not been immune from the challenges facing the global supply‐chain, and continues to feel the negative effects of the COVID‐19 pandemic.

The 2022 World PM Congress & Exhibition, organised by the European Powder Metallurgy Association (EPMA), was the latest event in this series, bringing over 1,000 visitors from the Powder Metallurgy industry to Lyon. Unfortunately, COVID restrictions in China prevented attendance from the world’s largest MIM part producing nation, and a more general reluctance to travel from other parts of Asia and North America – be it for health concerns or reduced travel budgets – resulted in a gathering that felt significantly more regional than past world congresses. Nevertheless, despite the majority of attendees coming from within Europe, the organisers reported that fifty-six countries were represented.

Mixed in among thought leaders from leading suppliers to injection molders and mold makers at the 2023 Molding and MoldMaking conferences will be molders and toolmakers themselves.

In terms of market breakdown, industrial machine parts accounted for 34.8% of sales (previous year: 29.3%), medical appliance parts accounted for 17.2% of sales (previous year: 18.2%) and automotive parts accounted for 13.1% of sales (previous year: 14.6%). Highlighted growth areas included industrial robot parts, with high demand expected as a result of the drive to automate global production lines. The JPMA’s MIM report also stated that a reshoring of MIM production was being experienced in Japan, with COVID-19 and geopolitical issues driving a return to domestic production. Fig. 9 shows a detailed breakdown of the MIM market in Japan in 2021.

The 2023 International Conference on Injection Moulding of Metals, Ceramics and Carbides (MIM2023), organised by the Metal Powder Industries Federa...»

HP’s Metal Jet has undergone significant refinement in the years since it was first unveiled in 2018. Now, by incorporating nearly the whole Bind...»

Whilst titanium MIM appears to be slow to develop in Japan, it was reported that developments relating to heat-resistant steels and spring steels are progressing. Concluding, the report stated that areas of highest concern were metal powder price increases and lead times.

The aim of this presentation is to guide you through the factors and the numbers that will help you determine if a robot is a smart investment for your application. Agenda: Why are you considering automation? What problems are you trying to solve? How and why automation can help Crunch the numbers and determine the ROI

Another factor behind the upbeat mood of European MIM producers is reshoring. One MIM producer stated that “reshoring is having a visible and very positive effect on MIM production in Europe, with parts coming back to Europe from China and India.” There were also suggestions that MIM’s end-users went through a restocking programme in 2021 – perhaps even overstocking – as they tried to anticipate future consumer demand.

Introduced by Zeiger and Spark Industries at the PTXPO, the nozzle is designed for maximum heat transfer and uniformity with a continuous taper for self cleaning.

Successfully starting or restarting an injection molding machine is less about ticking boxes on a rote checklist and more about individually assessing each processing scenario and its unique variables.

For Korea, the majority of MIM parts went to the automotive/transportation sector (80%), and the remainder to industrial (15%) and electrical (5%). In Thailand, the majority of MIM use was in industrial applications (60%), 20% in electronics, and 20% in other fields.

technotrans says climate protection, energy efficiency and customization will be key discussion topics at PTXPO as it displays its protemp flow 6 ultrasonic eco and the teco cs 90t 9.1 TCUs.

Core Technology Molding turned to Mold-Masters E-Multi auxiliary injection unit to help it win a job and dramatically change its process.

Reach a truly international audience that includes component manufacturers, end-users, industry suppliers, analysts, researchers and more.

Future growth is expected to come from both new applications as well as an expansion of existing markets. Additionally, MIM has never been in the headlines as much as it has with the rise of metal Additive Manufacturing, especially Binder Jetting. Has this heightened awareness driven business to the doors of MIM producers? Some believe so. Right now, MIM is far more capable of delivering parts to the necessary standards and volumes than any upcoming metal AM process. The reality is, however, that MIM remains a technology that is unknown to far too many designers and engineers and a concerted effort by the industry is required to improve this situation.

When, how, what and why to automate — leading robotics suppliers and forward-thinking moldmakers will share their insights on automating manufacturing at collocated event.

The value of Japan’s MIM sales in 2021 represents a 35.5% increase from the previous year. This, it was stated, was the result of the recovery demands in all markets following COVID-19, but especially in the strongly increasing demand for components for semiconductor manufacturing equipment. This is the first time since 2008 that MIM sales have passed the JPY 13 billion mark. “We have forecast that the strong demand of semiconductor manufacturing equipment parts will continue until the end of 2022, and the sales amount equal to or more than that in 2021 can be expected,” noted the JPMA report authors.

Neste announced a collaboration that will bring its RE, a polyethylene terephthalate derived from renewable and recycled material, to bottle production. The cooperation between Neste, Suntory, and Mitsubishi will enable the production of PET resin on a commercial scale.

Despite price increase nominations going into second quarter, it appeared there was potential for generally flat pricing with the exception of a major downward correction for PP.

Second quarter started with price hikes in PE and the four volume engineering resins, but relatively stable pricing was largely expected by the quarter’s end.

This review covers a large proportion of the global MIM industry; however, sales figures for many MIM producing countries in Asia, South America and elsewhere are not included. The data for China, Taiwan, Japan, India, Europe and North America alone, though, suggest an industry with annual sales in excess of $3 billion.

But what is certain is that the boundaries between MIM and sinter-based AM continue to blur. A significant percentage of MIM companies are seeing AM’s potential and diversifying into sinter-based metal AM. Here, Binder Jetting leads as previously suggested, but filament- or pellet-based Material Extrusion (MEX) and a number of viable process variants are also being commercialised. The motivation is clear – these technologies allow MIM firms to leverage installed sintering capacity and expertise, and take on parts that would previously have been turned away.

Metal Powder Industries Federation (MPIF) and its Metal Injection Molding Association (MIMA)www.mpif.org | www.mimaweb.org

As seen in Fig. 6, in 2021 the vast majority of China’s MIM parts went to the electronics sector, with the remainder delivered to automotive (4%), medical (4%), hardware (7%), and other industries (9%). Smartphone parts made up the majority of applications at 56%, followed by wearable electronics such as smartwatches at 12%, other applications at 9%, and computer components at 8%. In all, more than 75% of all MIM applications were for the consumer electronics industry.

The future for MIM in the crucial smartphone sector is somewhat unclear. Apple recently announced that it would be ending its use of the Lightning connector (Fig. 7) in favour of USB-C, a move that will result in the loss of an extremely high volume of MIM parts. However, the growing use of MIM components in elsewhere in smartphones, in tablets, laptops, smartwatches, headphones and headphone cases should offset these losses. Other MIM components that may also be at risk as smartphone designs evolve include volume buttons and SIM card trays. Opportunities for MIM hinges in any future folding devices could be significant. This would, however, depend on the continued growth in foldable device sales.

By value, the MPIF has reported that US MIM sales reached $520 million in 2021 (Fig. 11). In terms of markets, the firearms sector continues to dominate US MIM parts production, at 41%, by weight, of parts shipped. This is followed by medical devices at 24% by weight. Fig. 12 shows a full breakdown of US markets for MIM, based on an MPIF PM Industry Pulse Survey undertaken in August 2021. It should be noted that these US figures differ from those for Europe, China and Japan, where the market breakdowns are by sales value rather than weight.

In this three-part collection, veteran molder and moldmaker Jim Fattori brings to bear his 40+ years of on-the-job experience and provides molders his “from the trenches” perspective on on the why, where and how of venting injection molds. Take the trial-and-error out of the molding venting process.

Application data was presented for these countries during the ‘MIM in Asia’ plenary presentation. India saw a fairly even split across the various MIM application fields, with electronics holding a market share of 30% followed by transportation and other industries at 25% each, and industrial at 20%. It is estimated that in 2021 India generated MIM sales of around $300 million, with Indo-MIM accounting for a significant proportion of this.

Join Engel in exploring the future of battery molding technology. Discover advancements in thermoplastic composites for battery housings, innovative automation solutions and the latest in large-tonnage equipment designed for e-mobility — all with a focus on cost-efficient solutions. Agenda: Learn about cutting-edge thermoplastic composites for durable, sustainable and cost-efficient battery housings Explore advanced automation concepts for efficient and scalable production See the latest large-tonnage equipment and technology innovations for e-mobility solutions

Thousands of people visit our Supplier Guide every day to source equipment and materials. Get in front of them with a free company profile.

While the melting process does not provide perfect mixing, this study shows that mixing is indeed initiated during melting.

A new partner for Neste in Japan, ENEOS will use bio-intermediates based on Neste RE to produce bio-PX (Bio-Paraxylene) at its Mizushima Refinery in Okayama, Japan. The bio-PX will then be converted to PTA (Purified Terephthalic Acid) and subsequently to PET resin for Suntory to use to manufacture their PET bottles. Mitsubishi Corporation will be coordinating the collaboration between the value chain partners. “Through partnering along the value chain, Neste can contribute to reducing the polymers and chemicals industry’s dependence on fossil resources as well as to manufacturing of products that have a lower carbon footprint,” says Lilyana Budyanto, head of sustainable partnerships APAC at Neste Renewable Polymers and Chemicals business unit. A mass balancing approach will be applied to allocate the bio-based materials to the PET bottles.

The Plastics Industry Association (PLASTICS) has released final figures for NPE2024: The Plastics Show (May 6-10; Orlando) that officially make it the largest ever NPE in several key metrics.

Multiple speakers at Molding 2023 will address the ways simulation can impact material substitution decisions, process profitability and simplification of mold design.

In a time where sustainability is no longer just a buzzword, the food and beverage packaging industry is required to be at the forefront of this innovation. By adopting circular packaging processes and solutions, producers can meet regulatory requirements while also satisfying consumer demand and enhancing brand reputation. Join Husky to learn more about the broader implications of the circular economy — as well as how leading brands are leveraging this opportunity to reduce costs, increase design flexibility and boost product differentiation. Agenda: The cost and operational benefits of embracing circularity Key materials in circular packaging — including rPET and emerging bioplastics How to design a circular food and beverage package Strategies for selecting sustainable closures to future-proof packaging solutions Optimization and streamlining of production processes for enhanced efficiency How Husky Technologies can enable your sustainable success

In his presentation on the North American MIM market in the Special Interest Seminar on Global MIM markets at World PM2022, Stefan Joens, Elnik Systems, stated that growth in the North American MIM industry was mirrored by growth in production equipment sales. He also stated that new entrants were setting up MIM facilities in the US, and that many producers were now offering both MIM and Additive Manufacturing – with Binder Jetting being the most adopted AM process by MIM producers thanks to its potential for series production.

This month’s resin pricing report includes PT’s quarterly check-in on select engineering resins, including nylon 6 and 66.

Join this webinar to explore the transformative benefits of retrofitting your existing injection molding machines (IMMs). Engel will guide you through upgrading your equipment to enhance monitoring, control and adaptability — all while integrating digital technologies. You'll learn about the latest trends in IMM retrofitting (including Euromap interfaces and plasticizing retrofits) and discover how to future-proof your machines for a competitive edge. With insights from industry experts, it'll walk you through the decision-making process, ensuring you make informed choices that drive your business forward. Agenda: Maximize the value of your current IMMs through strategic retrofitting Learn how to integrate digital technologies to enhance monitoring and control Explore the benefits of Euromap interfaces and plasticizing retrofits Understand how retrofitting can help meet new product demands and improve adaptability Discover how Engel can support your retrofitting needs, from free consultations to execution

Fig. 3 shows a breakdown of the European MIM market by sector based on sales. Automotive, firearms and medical remain the largest markets – however, as Fig. 4 clearly shows, 2021 recorded a drop in the value of the automotive sector, whilst the value of the medical sector increased. Whether this is a sign of more permanent changes in the market for MIM parts in Europe remains to be seen, as supply chain challenges such as the semiconductor crisis were largely responsible for reducing automotive volumes in the period. The market for internal combustion engines (ICEs) continues to decline, however, with diesel’s share of the market falling from 27.9% to 19.6% in 2021, and petrol from 47.6% to 40%. Currently, MIM parts are used for both powertrain applications and other automotive applications such as suspension systems, sensors, thermal management and interior fittings, so the impact of the switch to vehicle electrification remains to be seen.

Speaking about the broad PM industry, including MIM, he stated that new production output levels are being achieved thanks to changes and innovations made because of the pandemic, and many companies report reductions in energy consumption, furnace atmosphere gases, scrap, and waste that is sent to landfills as a direct result of operating more efficiently. He also stated that some companies have also replaced older equipment with the latest computer controlled Industry 4.0 technology. This ‘Internet of Things’ approach allows equipment to ‘talk’ to each other and learn the best parameters for the process, and automation within the industry continues to grow as a solution to the overall shortage of skilled workers. From pick‐and‐place robots to 100% vision system inspections, automation is expected to continue to increase.

Discover how artifical intelligence is revolutionizing plastics processing. Hear from industry experts on the future impact of AI on your operations and envision a fully interconnected plant.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly