The Best Desktop Injection Molding Machines in 2024 - large plastic mould maker

Author:gly Date: 2024-09-30

Editor in chief of PlasticsToday since 2015, Norbert Sparrow has more than 30 years of editorial experience in business-to-business media. He studied journalism at the Centre Universitaire d'Etudes du Journalisme in Strasbourg, France, where he earned a master's degree.

"Our acquisition of Schnipke was driven by a focused strategy to deepen our capabilities, capacity, and technical superiority across the entire manufacturing process for medical device components,” said Vinc Ellerbrock, president and CEO of Atalys. “The addition of Schnipke adds two manufacturing sites for scalable growth, broadens our geographic presence and reach, enables us to serve a wider array of customers, and significantly augments our technical capabilities,” said Ellerbrock.

“I am truly excited to take this important next step with the team members from Nexa3D,” offered Jarfelt. “The packages we are offering to injection moulders are truly outstanding and we look forward to connecting with innovators and thought leaders in the US and elsewhere.”

In February, Atalys announced that it is tripling the size of its existing facility in the Dominican Republic from 15,000 to 47,000 square feet through the addition of a new 32,000-square-foot building. The company said that the new building will be dedicated to manual assembly with complementary injection molding, pad printing, tool repair, and warehousing. The existing facility will become the company's primary plastics processing site focused on cleanroom injection molding as well as secondary operations such as testing and packaging.

By aligning with Nexa3D, the NXE 400 platforms can now be used to print larger sized moulds, as well as larger volumes, with Nexa also making its wash and cure units available to FIM users. The two companies first connected at RAPID + TCT 2019 when they were both still to fully commercialise their respective technologies, and three years on have agreed that they can enhance the capabilities of FIM, and the accessibility to it, by partnering up.

In addition to its headquarters in Rochester, Atalys has manufacturing facilities in Asheboro, NC, and the Dominican Republic. The New York and North Carolina plants have multiple Class 8 cleanrooms for molding and assembly on site; the Santo Domingo site in the Dominican Republic offers cleanroom assembly and automation. The company said it adheres to scientific molding principles and is equipped with presses ranging in size from “near micro molding” to 1,400 tons.

“I had the opportunity to witness the powerful impact of Freeform Injection Molding for the first time at RAPID + TCT conference in 2019 and was instinctively intrigued by its potential to reimagine additive tooling,” added Nexa3D CEO & Chairman Avi Reichental. “As both AddiFab and Nexa3D have since productised and industrialised our respective processes, it became obvious that together, we can achieve much more by digitising injection moulding at convincing scale sustainably. I can’t wait to see the far-reaching impact of our collaboration.”

Earlier this week, another medical injection molder made news when Total Molding Services announced that it has been acquired by Haartz Family Holdings, changing its name to Moldgenix in the process.

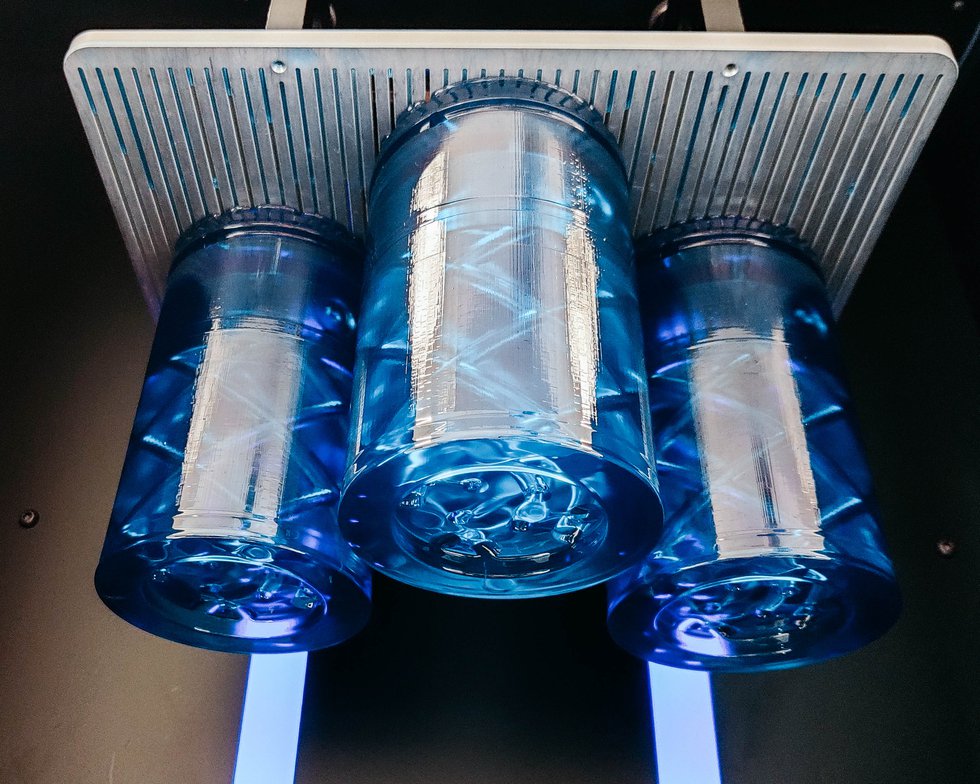

AddiFab introduced its FIM technology to market in 2019, promising customers the ability to additively manufacture complex injection mould tooling in hours, allowing them to validate designs before moving into production more quickly. The AddiFab FIM process sees mould tools 3D printed, placed in an injection moulding machine where a material will be pressed into the mould’s cavity, before the mould is then dissolved. Once the inlets and outlets have been removed, the final prototype part is revealed.

Since launching FIM in 2019, AddiFab has received investment from the EU, Mitsubishi Chemical’s venture arm and Western Hill Capital, with Mitsubishi then launching FIM services across three continents. In the meantime, Nexa3D has rolled out its NXE 400 and NXD 200 systems, with accompanying post-processing units, and a host of materials products. It has also worked to build out its leadership team, made the acquisition of NXT Factory, and has now moved to partner with another up-and-coming outfit in the AM space. A key component of the partnership will be the joint demo facilities in Palo Alto, which AddiFab co-founder and US Chief Commercial Officer Carsten Jarfelt will lead.

Founded in 1967, Schnipke has established a reputation for building tools in-house and designing and engineering molds that meet the medical device industry's stringent requirements for precision at extremely tight tolerances, said the news release. The company claims on its website that it can mold within tolerances of +/-0.001 inches and as small as 0.02 grams in weight. Even smaller dimensions can be accommodated upon customer request.

AddiFab and Nexa3D have partnered to offer Freeform Injection Molding (FIM) powered by NXE 400 stereolithography systems.

“Injection moulding is a complex process, and the tool building is the most complex part of the process,” AddiFab CEO Lasse Staal commented. “With Freeform Injection Molding, we provide injection moulders with a fully transparent set of tools that will allow them to fast-track tool designs and validations while raising the bar on tool innovation. Now, we can take these capabilities to the next level by partnering with Nexa3D to broaden access and superpower performance.”

Schnipke has tooling and plastic injection molding operations at its headquarters in Ottoville, OH, and operates a second manufacturing facility in Tucson, AZ. The company is FDA registered and is certified to ISO 13485:2016.

Plastics injection molder Atalys LLC announced yesterday that it has acquired Schnipke Engraving Co. LLC. Both companies provide injection molding and related services to medical device OEMs. Atalys, based in Rochester, NY, said the acquisition will enhance its manufacturing capabilities, technology, and geographical footprint.

The companies will set up joint Silicon Valley demo facilities in Pala Alto, California, showcase their joint solution at RAPID + TCT in May, and make the solution available via the Nexa3D reseller network.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly