Plastic Parts Direct launches 3D printed injection mould tool service - prototyp

Author:gly Date: 2024-09-30

“Mold grows very easily in small, hard-to-reach crevices that can be warm and moist for long periods of time,” says Siddiqui.

“Any product that frequently comes into contact with water or is routinely in a moist area is very susceptible to mold growth,” says Siddiqui. “And there’s even more of a chance of mold for items that have small holes or openings that are difficult to clean with soap and water — such as bath toys and sponges.” (Looking at you, rubber duckies.)

Due to this lack of uptake, the UK industry is missing some of the potential benefits of industrial robots, including improved productivity, efficiency and throughput. As a primary distributor of Shibaura Machine robots in the UK, the TM Robotics team has spotted opportunities for the injection moulding sector to reap the rewards of robotic automation.

“It’s very important parents don’t make their child throw up,” Sardar says. “It’s an antiquated practice that can hurt your child’s throat.”

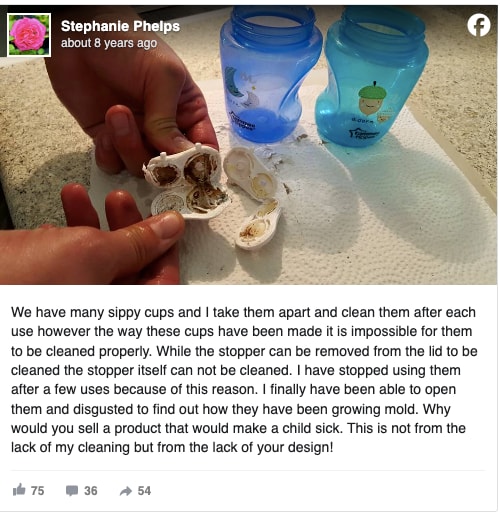

Additionally, the parts of sippy cups, which are notoriously difficult to clean, make these products even more attractive to mold.

“Mold itself is not considered dangerous to a healthy individual but can cause medical issues in someone who may be allergic,” says Siddiqui. “Symptoms such as congestion, sneezing, coughing and sometimes respiratory difficulties such as asthma may happen in people of the latter category. Children that are immunocompromised or have a weakened immune system due to medication or underlying medical conditions may be more sensitive to symptoms due to mold.”

Injection moulding applications have long played a key part in the UK’s manufacturing industry, producing everything from medical components, automotive parts, food containers, packaging items and much more. Traditionally, our manufacturers have relied on hydraulic-powered injection moulding machines in their operations. However, the industry is now at a crossroads, faced with the imperative to embrace technological advancements for sustainability and cost-effectiveness.

“Mold craves warmth and moisture — and when you add food particles to the mix, mold will find your child’s sippy cup irresistible,” Sardar says.

While sippy cups and the ubiquitous reusable water bottles with straws may be the great love of mold’s life, they aren’t the fungus’ only suitor.

It can happen to the most meticulous of parents. You take apart your child’s sippy cup or water bottle with the straw to wash it, or squeeze the excess bathwater from their rubber duckie — and staring back at you is that undeniable black gunk: mold. While the thought of mold growing inside your child’s cup or bath toys is, well, gross, try not to get too down on yourself, because it sneaks up on good parents everywhere.

According to Zahir Sardar, Pharm.D., specialist in poison information at the Poison Control Center at Children’s Hospital of Philadelphia, the reason mold often crops up in kids’ cups is because the conditions are just right.

The most obvious application for robots in mould machine shops is for the loading and unloading of injection mould machines. However, many end users currently have relatively low robotic ability, having traditionally chosen Cartesian X-Y gantry style robots to unload injection moulding machines.

The injection moulding process is responsible for up to 90 per cent of the Global Warming Potential (GWP) in the entire mould lifecycle. Recognising this, TM Robotics has championed investment in all-electric injection mould machines to replace older, more energy-intensive models.

And this wasn’t the first time a mold scandal rocked the parenting community either: A year prior, mold was found in GoGo Squeez Applesauce Pouches, and in 2018, an Indiana dad found mold in his child’s Capri Sun.

“It’s also advisable to check for allergies to mold with your doctor or allergist if you’ve found mold in your home,” she says.

So mold happens, but is this common fungus dangerous to your little one? Here’s what the experts have to say about mold in your child’s toys and sippy cups.

Sippy cups are pretty much a dream locale for the fungus, says Dr. Sara Siddiqui, a pediatrician and clinical assistant professor in the Department of Pediatrics at NYU Langone’s Hassenfeld Children’s Hospital in New York.

“If the answer is yes to either of these questions, chances are that a product will be a little more susceptible to mold growth,” he says. “Common examples are water expanding toys, stress balls, bath toys, sippy cups and water bottles.”

One notable observation is the prevalence of hydraulic legacy equipment that is still being used by UK manufacturers. The TM Robotics’ injection moulding servicing department has witnessed this first-hand and regularly visits manufacturing sites to service and maintain Shibaura Machine’s own hydraulic injection mould machines — some of which have been in action for up to three decades. On one hand, it is a testament to the resilience of these machines, but the industry must consider the environmental downsides of this ageing equipment.

If your child is experiencing abdominal pain, nausea or vomiting after you discover mold in their sippy cup, Siddiqui suggests checking in with their doctor.

In 2016, parents of young kids were (understandably) taken aback when two moms posted photos of mold in Tommee Tippee sippy cup valves on Facebook.

Nigel Smith, managing director of TM Robotics, the international distribution partner of Shibaura Machine and the UK and Ireland distributor of its injection mould machines, explores the changing landscape of plastic's injection moulding sector and argues the case for investment in new technologies, both for better operational efficiency and improved sustainability.

The flagship all-electric range from TM Robotics is the SXIII all-electric series from Shibaura Machine. Shibaura Machine is the new name for Toshiba Machine — the Japanese manufacturer of industrial robots and injection mould machines. The SXIII range boasts faster injection speeds, enhanced sustainability and a streamlined design when compared to its hydraulic predecessors. What’s more, despite the perception of higher costs for all-electric machines, this range can improve cost efficiency by lowering the cost-per-part.

If you’re unsure if a product of your child’s is susceptible to growing mold, Sardar recommends asking yourself the following two questions: Is this product good at holding onto moisture? Are there cracks or pores that saliva or food can get trapped in?

“Mold is all around us, and we breathe in and swallow some mold every day,” Sardar says. “The type of mold, the length of time someone was exposed to mold, how they were exposed to mold and an individual’s own medical history makes each case of mold exposure unique. However, it makes sense to keep exposure to mold as low as we can reasonably manage.”

If you find mold on your child’s toy or on their bath sponge, remember there’s a good chance they didn’t ingest it — in which case, there’s nothing to worry about. And even if they did (i.e. they swallowed some bath water), in most cases, it was likely a small amount and won’t do any harm. In rare cases, kids who are sensitive to mold may experience vomiting, upset stomach or diarrhea after ingestion, according to Cincinnati Children’s Hospital.

This was demonstrated by TM Robotics’ customer Lotan, a manufacturer of plastic containers based in Leicestershire, UK. Lotan’s production facility exclusively uses all-electric injection mould machines from Shibaura Machine. The SXIII provides significantly faster injection speeds than traditional moulding equipment, providing 35% faster cycle times than conventional hydraulic servo IMMs.

Care.com does not employ any caregiver and is not responsible for the conduct of any user of our site. All information in member profiles, job posts, applications, and messages is created by users of our site and not generated or verified by Care.com. You need to do your own diligence to ensure the job or caregiver you choose is appropriate for your needs and complies with applicable laws.

There are over 5,800 companies operating in the UK plastics industry, contributing £25 billion to our economy each year. As a key player in Britain’s manufacturing sector, injection mould shops must embrace technological advancements in injection moulding machinery and accompanying automation for improved profit, productivity and sustainability.

Another area of debate in the injection moulding world is robot integration. The UK seriously lags behind other developed countries for its number of robot installations. That’s not just for the world of injection moulding, but in the UK manufacturing sphere more widely. In fact, the International Federation of Robotics (IFR) reports that the UK has just 101 robots per 10,000 employees — rookie numbers compared to competitors in the US, China and Germany.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly