One Start-Up’s $20M Boost To Bring Injection Molding Back To The U.S. - injectio

Author:gly Date: 2024-09-30

We are confident about the unique quality of our Company Profiles. However, we want you to make the most beneficial decision for your business, so we offer a free sample that you can download by submitting the below form

ALPLA North America managing director James Rooney said: “We are excited about our new Kansas City site which represents a key element of our growth strategy and our continued commitment to the expansion of our injection moulding capabilities.”

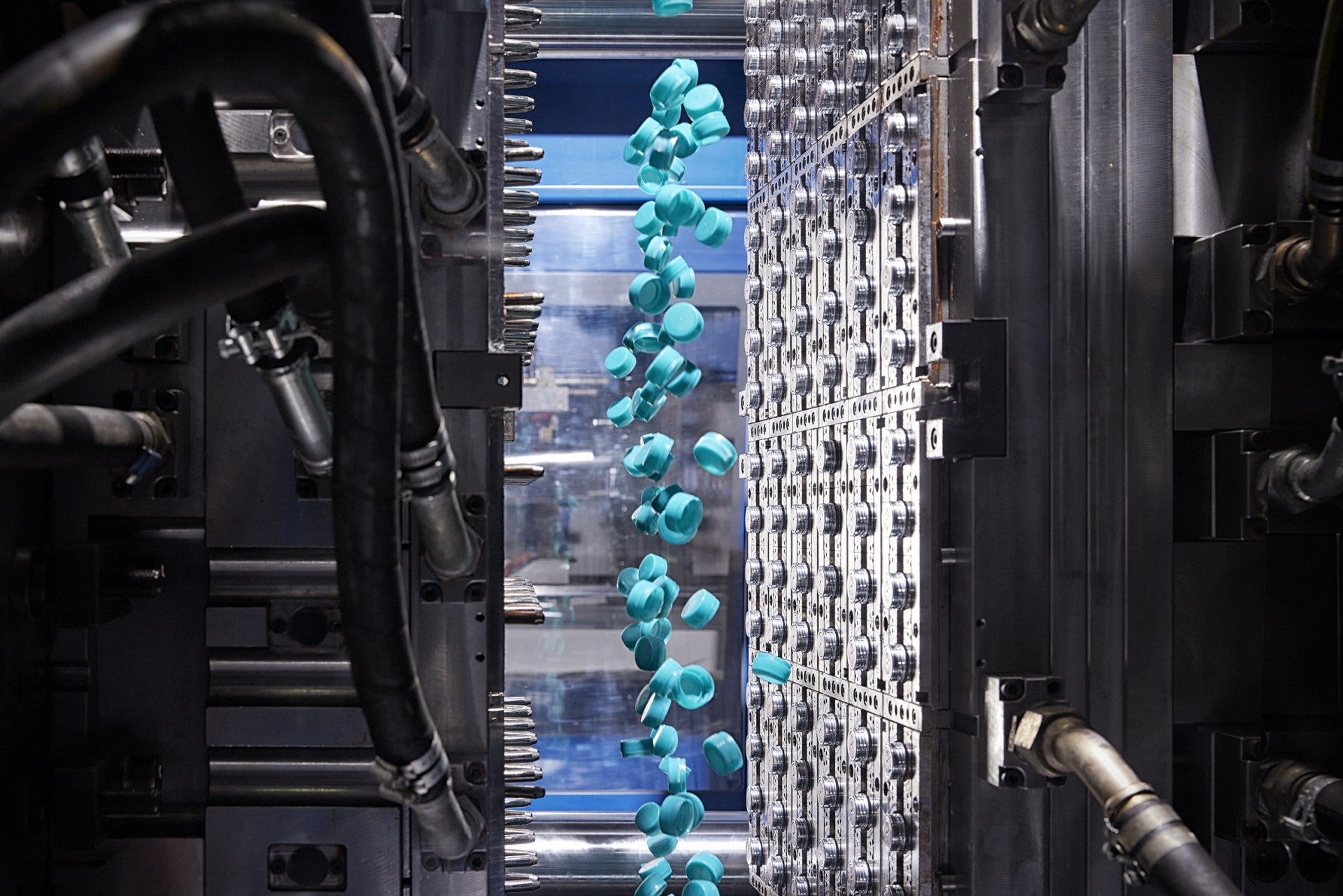

Plastic manufacturer ALPLA North America has chosen Kansas City in Missouri to construct its new injection moulding facility.

Borealis has unveiled Borcycle GD3600SY, a glass-fiber-reinforced polypropylene (PP) compound with 65% post-consumer recycled (PCR) polymer content. It first will be used in automotive interiors in a landmark project delivered in partnership with Plastivaloire, a thermoplastic injection specialist and Tier 1 supplier to the automotive sector, and OEM Stellantis, the owner of 14 automotive brands including Chrysler, Jeep, and Fiat.

Stephen has been with PlasticsToday and its preceding publications Modern Plastics and Injection Molding since 1992, throughout this time based in the Asia Pacific region, including stints in Japan, Australia, and his current location Singapore. His current beat focuses on automotive. Stephen is an avid folding bicycle rider, often taking his bike on overseas business trips, and a proud dachshund owner.

“In the automotive market, Borealis introduced Borcycle GD3600SY in Q4 2023,” added Danielly Pierozan Cortes, global head of Resins & Compounds at Stellantis. “Stellantis is the leading OEM implementing this technology, deploying it in our center console carriers in vehicle interiors. This reinforces our commitment to sustainability by engaging our supply base in a shared journey toward circularity.”

This development proactively addresses the expected requirements of the forthcoming European end-of-life vehicle regulation. This stipulates that 25% of the plastic used in new vehicles must come from recycled sources, with a clear focus on mechanical and post-consumer recycling. Given that PP accounts for about one-third of the plastic in cars, compounds like Borcycle GD3600SY will play a critical role in achieving these circularity goals.

Shanila Baseley, Borealis’ global commercial vice president, Advanced Products & Mobility, Commercial Excellence & Business Intelligence, stated: “Accelerating the transition to a circular economy requires strong partnerships and innovative approaches. We are proud that our collaboration with Plastivaloire and Stellantis in the spirit of EverMinds has resulted in this significant step toward sustainability in the automotive sector and is further evidence of our commitment to reinventing essentials for sustainable living.”

Historically, mechanically recycled plastics from post-consumer waste streams have been of low and inconsistent quality, making them unsuitable for demanding automotive applications. However, advanced recycling technologies like Borcycle M have overcome these limitations: By combining sorting, cleaning, and extrusion steps, household waste streams are converted into high-quality PCR polymers that meet the demanding standards of the automotive industry while also advancing circularity.

“Developed and manufactured in France, the center console structure of the new Peugeot 3008, produced with Borealis’ new Borcycle M GD3600SY grade, is a major step toward a more sustainable automotive industry,” said Dominique Manceau, innovation director at Plastivaloire.

The center console made from Borcycle GD3600SY incorporates 30% glass-fiber reinforcement, essentially meaning more than 90% of the resin matrix is made of recycled polypropylene. Image courtesy of Borealis.

Missouri Governor Mike Parson said: “ALPLA’s decision to grow in Missouri demonstrates our state’s ability to support companies with our highly skilled workforce, affordable business costs and unmatched logistical advantages. We are home to global leaders across various industries, and we take great pride in providing companies like ALPLA with a solid foundation to ensure their success in Missouri.”

The glass-fiber-reinforced polypropylene will be used in center consoles of new Peugeot 3008, the first time a compound with a high PCR percentage has been used in a large automotive interior application.

Last month, ALPLA, together with Ecohelp and Switzerland’s United Polymer Trading, announced an investment in the construction of a recycling plant in Targu Mures, Romania.

Borcycle GD3600SY is part of the Borcycle M portfolio of mechanically recycled polyolefins for demanding applications. It contains 30% glass fibers, meaning that almost the entire polymer portion of the product is made from post-consumer recycled PP. It will initially be used in center console carriers for the new Peugeot 3008, marking the first instance of a compound with 65% PCR PP being used in series production for large automotive interior applications.

ALPLA received support from commercial real estate service firm Cushman & Wakefield and Kansas City Area Development Council for the project.

Expected to commence operations in the fourth quarter of next year, the facility is strategically located to better serve customers in the Midwest and fulfil the demand for its products.

Access the most comprehensive Company Profiles on the market, powered by GlobalData. Save hours of research. Gain competitive edge.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly