New Multicomponent Injection Molding Machine Line Launches - 2k molding

Author:gly Date: 2024-09-30

In terms of physical space, individual employees and machine fleet, the two groups in this year’s benchmarking survey were virtually indistinguishable. The average floor space of a Top Shops entrant was 88,184 ft2, with the rest averaging 79,614 ft2. Total employees at Top Shops averaged 95 vs. 98 at other entrants, with workers directly involved in plant-floor operations coming in at 73 for Top Shops and 78 at all others.

While the major correction in PP prices was finally underway, generally stable pricing was anticipated for the other four commodity resins.

Mass production with 3D printing is making inroads in areas where it commercially makes sense, with hearing aids the most significant area of early widespread adoption. Consumers are walking on shoes with 3D printed midsoles, purchased at retail, or with personalized insoles made to fit their feet via a smartphone app. Medical products, like prosthetics and orthotics, can also be made specifically for a wearer. Produced together with traditional techniques, 3D printing supplements an overarching process to create next-generation end-use products.

Mike Sepe has authored more than 25 ANTEC papers and more than 250 articles illustrating the importance of this interdisciplanary approach. In this collection, we present some of his best work during the years he has been contributing for Plastics Technology Magazine.

Join this webinar to explore the transformative benefits of retrofitting your existing injection molding machines (IMMs). Engel will guide you through upgrading your equipment to enhance monitoring, control and adaptability — all while integrating digital technologies. You'll learn about the latest trends in IMM retrofitting (including Euromap interfaces and plasticizing retrofits) and discover how to future-proof your machines for a competitive edge. With insights from industry experts, it'll walk you through the decision-making process, ensuring you make informed choices that drive your business forward. Agenda: Maximize the value of your current IMMs through strategic retrofitting Learn how to integrate digital technologies to enhance monitoring and control Explore the benefits of Euromap interfaces and plasticizing retrofits Understand how retrofitting can help meet new product demands and improve adaptability Discover how Engel can support your retrofitting needs, from free consultations to execution

A nearly identical number of all survey participants said their facilities featured an in-house tool room (78% of Top Shops and 77% of all others), with both groups utilizing them in equal measure for mold building (rather than just repairs)—44% of Top Shops and 41% of other entrants. While 36% of Top Shops’ molds featured hot runners, only 22% of tools at the other facilities applied this technology. Only 9% of the Top Shops’ tools and 8% of the other entrants’ molds had more than 16 cavities.

At the start of 2021, as it does every year, Plastics Technology asked injection molders to look back on the year prior and take stock of their operations. The only difference this time: COVID-19.

Those challenges, just like the virus, didn’t stop at the border. Aida Cecilia Mercado Salazar of Mexican Top Shop molder and moldmaker IEMSA in San Luis Potosi, said her company had to adapt to and embrace how the pandemic changed day-to-day life and work. “The first big challenge was to get used to the new normal,” Salazar says, citing the two most recognizable aspects of the pandemic: masks and uncertainty. “In the beginning, we were scared because we didn’t know how safe we actually were.” Ultimately, IEMSA, like so many of the molders we surveyed, never halted operations and came through the crisis even stronger. “We became a closer team, and because of that trust it was easier to overcome the challenges in the way.”

Processors with sustainability goals or mandates have a number of ways to reach their goals. Biopolymers are among them.

Fully 70% of Top Shops perform regular, formal business reviews, compared with 54% of others, with 83% of Top Shops applying business-metric goal setting vs. 42% of others. And 87% of Top Shops have regular management meetings, compared with just 63% of others.

In a time where sustainability is no longer just a buzzword, the food and beverage packaging industry is required to be at the forefront of this innovation. By adopting circular packaging processes and solutions, producers can meet regulatory requirements while also satisfying consumer demand and enhancing brand reputation. Join Husky to learn more about the broader implications of the circular economy — as well as how leading brands are leveraging this opportunity to reduce costs, increase design flexibility and boost product differentiation. Agenda: The cost and operational benefits of embracing circularity Key materials in circular packaging — including rPET and emerging bioplastics How to design a circular food and beverage package Strategies for selecting sustainable closures to future-proof packaging solutions Optimization and streamlining of production processes for enhanced efficiency How Husky Technologies can enable your sustainable success

Looking more deeply into the numbers, while the Top Shops and the other respondents were very close in average fleet size, the presses on Top Shops’ floors had considerably less miles on them, boasting an average age of nine years compared with 14. The Top Shops ran horizontal machines exclusively, while 9% of the other facilities also had vertical presses in their plants. Top Shops operated slightly fewer hydraulic machines (62% vs. 71%) than other survey entrants; and far more all-electric presses (65% vs. 50%) and hybrid (50% vs. 26%) machines.

The new kid on the production block, 3D printing, can be an exciting meet-cute — new shapes, complex forms, high-value/low-volume production, all built layer by layer to increasingly exacting standards. Ideated since the 19th century, with modern patents tracing to the 1980s, 3D printing rethinks manufacturing from the first layer. More oversight, standards, and validation are seeing the technology move more into the production world and finally, finally begin fulfilling what had been overblown early promises.

Despite price increase nominations going into second quarter, it appeared there was potential for generally flat pricing with the exception of a major downward correction for PP.

While the melting process does not provide perfect mixing, this study shows that mixing is indeed initiated during melting.

technotrans says climate protection, energy efficiency and customization will be key discussion topics at PTXPO as it displays its protemp flow 6 ultrasonic eco and the teco cs 90t 9.1 TCUs.

PlastiCert’s Porter says his company’s location in a small, rural farming community in Minnesota situated between two large cities equates to a shallow talent pool. Its answer to that geographic challenge: “First and foremost, we have created a desirable and accommodating workplace environment, resulting in turnover being practically negligible,” Porter says. The company has also sought to raise its visibility in the community and to partner with a nearby state university for a stream of interns.

Sustainability continues to dominate new additives technology, but upping performance is also evident. Most of the new additives have been targeted to commodity resins and particularly polyolefins.

Formnext Chicago is an industrial additive manufacturing expo taking place April 8-10, 2025 at McCormick Place in Chicago, Illinois. Formnext Chicago is the second in a series of Formnext events in the U.S. being produced by Mesago Messe Frankfurt, AMT – The Association For Manufacturing Technology, and Gardner Business Media (our publisher).

Join Wittmann for an engaging webinar on the transformative impact of manufacturing execution systems (MES) in the plastic injection molding industry. Discover how MES enhances production efficiency, quality control and real-time monitoring while also reducing downtime. It will explore the integration of MES with existing systems, emphasizing compliance and traceability for automotive and medical sectors. Learn about the latest advancements in IoT and AI technologies and how they drive innovation and continuous improvement in MES. Agenda: Overview of MES benefits What is MES? Definition, role and brief history Historical perspective and evolution Longevity and analytics Connectivity: importance, standards and integration Advantages of MES: efficiency, real-time data, traceability and cost savings Emerging technologies: IoT and AI in MES

“We are very open and honest with our employees and communicate frequently on the state of our business and outlook,” Murphy says. “We have always had a great culture at PRD where everyone feels like family. For some it is just a job, but many feel ownership and accountability for our success. We try to provide clear production goals, learn from our mistakes and celebrate our successes.”

Thousands of people visit our Supplier Guide every day to source equipment and materials. Get in front of them with a free company profile.

Across the show, sustainability ruled in new materials technology, from polyolefins and engineering resins to biobased materials.

In this collection, which is part one of a series representing some of John’s finest work, we present you with five articles that we think you will refer to time and again as you look to solve problems, cut cycle times and improve the quality of the parts you mold.

A quick checklist of when it makes sense to pivot production toward AM would include parts that fall under some of these categories:

As for their fleets’ clamp-force ranges, Top Shops and other entrants tracked closely in the 0-100, 101-500, and 501-1000-ton ranges, but only 9% of Top Shops utilized machines over 1000 tons, vs. 15% of other entrants. Top Shops also offered more specialty injection molding technologies, outstripping other entrants in providing two-shot, gas/water-assist, in-mold label and insert molding.

This month’s resin pricing report includes PT’s quarterly check-in on select engineering resins, including nylon 6 and 66.

With capabilities in polymers, metals, pastes, and even bio-materials, there are few material areas that 3D printing hasn’t begun to explore. There is, naturally, a hefty chasm between lab exploration and real-world application, and that’s one that 3D printing has begun to bridge tidily.

Mold maintenance is critical, and with this collection of content we’ve bundled some of the very best advice we’ve published on repairing, maintaining, evaluating and even hanging molds on injection molding machines.

Multiple speakers at Molding 2023 will address the ways simulation can impact material substitution decisions, process profitability and simplification of mold design.

3D printing’s sweet spot is in high-value, low-volume production, the opposite of injection molding. Here’s the good, bad, and ugly of both technologies, and advice on when it makes sense to pivot from one to the other.

On the equipment side, the average fleet size for Top Shops and the other respondents registered at 21 and 20 injection molding machines, respectively. So, we are looking at basically the same amount of workers utilizing the same amount of machines in the same amount of space for the two groups, but there are also some key differences.

When, how, what and why to automate — leading robotics suppliers and forward-thinking moldmakers will share their insights on automating manufacturing at collocated event.

AM remains a nascent technology, for all its recent growth and maturation. Adopting the technology for the first time requires a major learning curve as product designers well versed in DFM have a new skill set to gain in DfAM — design for additive manufacturing. Risk-averse sectors where validation is critical and new installations expensive in terms of training and investment are hesitant to adopt before they understand a full ROI. Often, adoption relies on a single internal champion, and AM-using departments tend to run as something of a startup inside an established company.

PRD’s Murphy says his company has thrown people and automation at the skills gap, which is “by far the biggest challenge. We have implemented automation where possible, increased wages, and gone out of our way to ensure our employees know how much we appreciate them,” including discretionary bonuses. “Unfortunately, I don’t hear anyone with a good answer to the predicament we find ourselves in. Everyone talks about the end of extra unemployment benefits, and while they do not help the situation, I am not convinced this well be the solution.”

Establishing and understanding the break-even point of cost-versus-quantity will often inform the decision for when to adopt which manufacturing process. Considerations obviously differ from batch sizes of 2 to 25 to 250 to 250,000.

Gifted with extraordinary technical know how and an authoritative yet plain English writing style, in this collection of articles Fattori offers his insights on a variety of molding-related topics that are bound to make your days on the production floor go a little bit better.

For all the new materials coming into AM — with giants like Arkema, BASF, Evonik, Henkel, Sabic, and many more dipping their toes in the 3D-printed waters — the overall portfolio is exponentially smaller compared to what’s available for traditional manufacturing.

Resin drying is a crucial, but often-misunderstood area. This collection includes details on why and what you need to dry, how to specify a dryer, and best practices.

On the non-people or robotic side, 52% of Top Shops increased automation in 2020, compared with 35% of the rest of the shops surveyed. Those investments add to an already sizable fleet of robots for top shops, fully 96% of whom said their facilities used automation, compared with 68% of others.

Start by picking a target melt temperature, and double-check data sheets for the resin supplier’s recommendations. Now for the rest...

Sarah Goehrke is the founder of AM-specific contract services company Additive Integrity and sits on the Board of Advisors for the Additive Manufacturing Coalition. She focuses in the additive manufacturing industry on advances in diversity, sustainability, and ecosystem positioning with a heightened focus on messaging. Goehrke has been a leader in the 3D-printing industry since 2014, previously serving as the Managing Editor of Fabbaloo; Editor-in-Chief of 3DPrint.com; and Senior Director, Strategic Communications and Ecosystems at ultrafast 3D-printing leader Nexa3D. Through Additive Integrity, she has worked with more than two dozen companies across the industry, contributed to publications including Forbes.com, and keynoted across three continents. She is deeply and actively passionate about advancing diversity, equity, and inclusion in the 3D-printing industry. Goehrke holds bachelor’s degrees in English and Theatre from Muskingum College, as well as a certificate in Diversity & Inclusion for HR from Cornell University.

Discover how artifical intelligence is revolutionizing plastics processing. Hear from industry experts on the future impact of AI on your operations and envision a fully interconnected plant.

Fully 83% of Top Shops and 80% of other shops experienced a skills gap in 2020, with all participants looking to address the issue, just in different ways. On the people side, Top Shops outstripped other respondents in flexible schedules, mentor programs, and outreach at local schools by 18, eight and 26 percentage points, respectively. As for partnering with area schools for open houses or staff recruitment, 64% of Top Shops took that step, while only 28% of the other respondents did so.

Second quarter started with price hikes in PE and the four volume engineering resins, but relatively stable pricing was largely expected by the quarter’s end.

“The biggest challenge was the unknown,” explains Mark Murphy, president of molder and moldmaker PRD Inc. in Springville, Ind.—one of PT’s 23 newest Top Shops. “We had gone for so many years with growing sales and a growing economy. We knew this could probably be the event that brought it all to a halt.”

Standards, while also coming more into play, are also lagging. Many potential adopters cannot even consider 3D printing, as defense and other government-mandated organizations are limited in the scope of processes on the table. Until more standards are recognized and more support comes from all levels — such as with President Biden’s 2022 AM Forward initiative expanding reach nationally, locally, and internationally — adoption will remain lower than theoretically possible.

The biggest pro for additive manufacturing is perhaps also its biggest con: The sweet spot is in high-value, low-volume production. This is counterbalanced by injection molding’s sweet spot, which is just the opposite.

While this is technically a survey of injection molders, in reality, nearly all of its participants are more accurately described as contract manufacturers. A purchase order for molding a single component dropped from the cavity with nothing else done to it—inspection, decoration, assembly, packaging—is most definitely not the business model for today’s molders. Fully 78% of Top Shops and 81% of other shops provide assembly for customers, with 70% of Top Shops and 60% of the remaining survey respondents offering customers collaborative design services. Where Top Shops go even further is in shipping/packaging/labeling, with 87% of our honorees providing those services, compared with 66% of others.

As with any tool in a toolbox, nuance is vital to the appropriate application of solution to challenge. When all you have is a hammer, after all, everything looks like a nail. Today’s toolbox is substantially more robust, leaving us with options and the wherewithal to make informed decisions: When do I need a hammer? When do I need something else?

In this three-part collection, veteran molder and moldmaker Jim Fattori brings to bear his 40+ years of on-the-job experience and provides molders his “from the trenches” perspective on on the why, where and how of venting injection molds. Take the trial-and-error out of the molding venting process.

“The biggest challenges were maintaining operations, assuring customers that we were taking steps to sustain their order flow, and keeping our coworkers safe,” says Craig Porter, president and owner of another Top Shop, PlastiCert in Lewiston, Minn. “As a small manufacturer, keeping track of COVID legislation, mandates and programs around finances for the company and our employees was a full-time job for people that typically already wear multiple hats.”

The strongest use case for any manufacturing process is, at its heart, straightforward. Use what makes sense. There is no single solution to meet every challenge. Each part, each end-use product, has unique specifications and, in an ideal world, should be approached individually. Take the time to understand the exact needs, explore available solutions, and narrow down to what makes the most sense for your application in terms of expense, time, expertise, and final product.

Well-known as it may be, the design for manufacturing process for IM is lengthy and often non-linear. As a molding-based technology, IM relies on removable molds, which stifle the ability to design for low part counts and complex internal geometries. Further, creating those molds can add weeks to months to a production timeline.

As some of today’s largest applications, like the adidas 3D-printed midsole, highlight, the best ultimate solution is to use the technologies that make sense where they make sense. Often, this is a complementary, rather than an either-or, solution. 3D-printed injection molds, for instance, offer an interesting combination of desirable traits for an overall fitting solution.

Plastics Technology covers technical and business Information for Plastics Processors in Injection Molding, Extrusion, Blow Molding, Plastic Additives, Compounding, Plastic Materials, and Resin Pricing. About Us

3D printing first made headlines as a half-Star Trek, half-everyman technology that brought science fiction to the kitchen table. Gassed-up media reports positioned the technology as an “anyone can make anything” process. Unsurprisingly, no such process exists with push-button precision. Mainstream perceptions dimmed, dismissing the technology.

Because of the wrinkle of the global pandemic, or perhaps in spite of it, Plastics Technology’s annual Top Shops survey received its best-ever response as injection molders seemed anxious to take a deep dive into operations that stayed open as essential businesses, while other segments of the broader economy faltered.

In this collection of articles, two of the industry’s foremost authorities on screw design — Jim Frankand and Mark Spalding — offer their sage advice on screw design...what works, what doesn’t, and what to look for when things start going wrong.

Scale, speed, uniformity — injection molding ticks the right boxes for high-volume production. Able to reliably handle a huge array of materials, injection molding offers predictability and quality.

Markets served for both groups largely mirror each other, except for two sectors: medical/healthcare and building/construction. While 74% of the other respondents serve the building/construction market, only 35% of Top Shops generate business from it. And 74% of Top Shops have medical customers, vs. 54% of other survey respondents.

In fact, average plant-floor employee age, plastics/manufacturing experience, turnover rate and hourly wages were nearly identical for all survey participants—41/40 yrs; 17/16 yrs; 17/16% ; and $17/$16—for Top Shops/Others in all those categories, respectively.

Now in its fifth year, this benchmarking survey of injection molders queries participants on demographic data, performance indicators, and business and process strategies. A selection of those performance metrics are then scored, with the highest scoring companies named Top Shops for 2021 based on their 2020 operations. The Top Shops display some stark contrasts with all other entrants, but in many ways they are quite similar.

Tried and true, injection molding (IM) has made its stand for decades. Patented in the late 1800s, IM boomed decades later as WWII demanded low-cost, high-volume production. It can hardly be said to have slowed since. Nearly ubiquitous in modern manufacturing environments, IM is perhaps best described as the devil you know; it has its kinks and limitations, but it’s familiar and generally reliable. Could IM, though, be displaced by newcomer AM?

Learn about sustainable scrap reprocessing—this resource offers a deep dive into everything from granulator types and options, to service tips, videos and technical articles.

August 29-30 in Minneapolis all things injection molding and moldmaking will be happening at the Hyatt Regency — check out who’s speaking on what topics today.

The single most important thing to keep in mind when adopting AM is a simple one: Just because you can doesn’t always mean you should. It makes the most sense to stick with injection molding for:

The new industrial event from the publisher of Plastics Technology will feature data, sourcing and technology updates for manufacturing businesses, including injection molders.

“We listen to each others’ ideas to make the best choices and become closer as a team,” IEMSA’s Salazar says. “We also allow doubts and mistakes to happen—we let the learning process be part of our daily life—always taking care of the situation and solving the issues.”

Across all process types, sustainability was a big theme at NPE2024. But there was plenty to see in automation and artificial intelligence as well.

Successfully starting or restarting an injection molding machine is less about ticking boxes on a rote checklist and more about individually assessing each processing scenario and its unique variables.

Five industry pros with more than 200 years of combined molding experience provide step-by-step best practices on mounting a mold in a horizontal injection molding machine.

Say “manufacturing automation” and thoughts immediately go to the shop floor and specialized production equipment, robotics and material handling systems. But there is another realm of possible automation — the front office.

On the injection side, this firm deploys all-electric presses with integrated parts-handling robots and machine-monitoring systems that can run unattended. “We also mounted cameras strategically throughout our facility so remote operators can log in from their phones.”

Join KraussMaffei for an insightful webinar designed for industry professionals, engineers and anyone interested in the manufacturing processes of PVC pipes. This session will provide a comprehensive understanding of the technology behind the production of high-quality PVC pipes: from raw material preparation to final product testing. Agenda: Introduction to PVC extrusion: overview of the basic principles of PVC pipe extrusion — including the process of melting and shaping PVC resin into pipe forms Equipment and machinery: detailed explanation of the key equipment involved — such as extruders, dies and cooling systems — and their roles in the extrusion process Process parameters: insight into the critical process parameters like temperature, pressure and cooling rates that influence the quality and consistency of the final PVC pipes Energy efficiency: examination of ways to save material and energy use when extruding PVC pipe products

Core Technology Molding turned to Mold-Masters E-Multi auxiliary injection unit to help it win a job and dramatically change its process.

Plastics Technology’s 2020 Top Shops benchmarking survey reveals that the most effective molders are, not surprisingly, the most efficient, accomplishing more than their peers from a smaller manufacturing footprint.

The aim of this presentation is to guide you through the factors and the numbers that will help you determine if a robot is a smart investment for your application. Agenda: Why are you considering automation? What problems are you trying to solve? How and why automation can help Crunch the numbers and determine the ROI

While prices moved up for three of the five commodity resins, there was potential for a flat trajectory for the rest of the third quarter.

Materials run by our survey entrants largely tracked along similar lines, with other shops running slightly more polyolefins than Top Shops (63% to 52%), while Top Shops processed more engineering resins (87% to 76%). Only in LSR and bioplastics was the gap noticeably wide, with 9% of Top Shops running LSR and 17% bioplastics, compared with 2% and 7%, respectively, for other plants.

Jim Goerges, president of Precision Tool Technologies Inc. (PTT) in Brainerd, Minn., another Top Shops honoree, says that even before the pandemic, the company had a goal of unattended machining through all 168 hr in a work week, investing in lights-out capable machines over the years to get there. “Our investment in the right automated machining technologies put us in a strong position to navigate the issues related to increased social distancing during the pandemic,” Goerges says.

The AM benefits for production are many. Complex internal structures can be incorporated directly into a single finished piece as the full product is produced at one time, reducing part counts as well as weak points of connection. Lightweighting, such as with lattice structures or simply through reduced part count, is desirable in weight-conscious industries like aerospace and automotive, where every ounce matters. A faster time-to-market is also a prime consideration as 3D printers can localize production. Importantly, 3D printing also forestalls the need for tooling, removing a time-intensive stage of many manufacturing processes. More validated materials are coming to market all the time, as well, bringing familiar materials to a new stable.

With newer solutions coming to market and proving out their claims, injection molding is poised to lose some of its dominance in production.

Meetings may be the bane of many in the business world, and certainly the running butt of a slew of jokes, but the communication, goal setting and goal measuring that well-designed and organized meetings facilitate are very much a part of Top Shops’ winning strategies.

Additive technology creates air pockets in film during orientation, cutting down on the amount of resin needed while boosting opacity, mechanical properties and recyclability.

In this collection of content, we provide expert advice on welding from some of the leading authorities in the field, with tips on such matters as controls, as well as insights on how to solve common problems in welding.

Overall, IM can reliably produce parts with known quality at high quantity — but it takes a while. When lower-volume end-use product runs are required, injection molding may add time and molding costs that counterbalance desirable ROI.

Introduced by Zeiger and Spark Industries at the PTXPO, the nozzle is designed for maximum heat transfer and uniformity with a continuous taper for self cleaning.

Injection molding is a well-understood and go-to manufacturing process, but naturally isn’t without its limitations. The learning curve and expense of setting up an IM installation are significant, as is the ramp-up time to actually producing a new design.

While prices moved up for three of the five commodity resins, there was potential for a flat trajectory for the rest of the third quarter.

The 2019 Plastics Technology Top Shops Survey shows that for its highest-rated respondents, injection molding is just one element in a growing suite of services and capabilities offered to customers.

What had been overblown promises about a decade ago are now deliverables: Production, scale, quality, validation, and volume are now end-use realities.

Take a deep dive into all of the various aspects of part quoting to ensure you’ve got all the bases—as in costs—covered before preparing your customer’s quote for services.

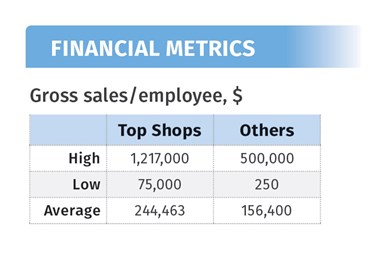

Where the gap between the groups widens further is the volume of resins processed, with Top Shops nearly doubling the other entrants’ poundage, running an average of 22.3 million lb of material in 2020 vs. 12.5 million lb average for the others. In addition to more material, our honorees processed more kinds of resins. Top Shops ran an average of 43 different material categories, compared to 18 for the remaining survey participants.

After successfully introducing a combined conference for moldmakers and injection molders in 2022, Plastics Technology and MoldMaking Technology are once again joining forces for a tooling/molding two-for-one.

Further, bridge production is increasingly showing its value as 3D printing begins what injection molding can finish at scale. Especially critical during early days of the COVID-19 pandemic, when personal protective equipment (PPE) and necessary parts for ventilators were in short supply and need-it-now high demand, 3D printing stepped up to outfit medical professionals and patients with what they needed while IM ramped up to meet broader demand. Some remain in use, as 3D printing may have enhanced testing devices’ efficacy.

Join Engel in exploring the future of battery molding technology. Discover advancements in thermoplastic composites for battery housings, innovative automation solutions and the latest in large-tonnage equipment designed for e-mobility — all with a focus on cost-efficient solutions. Agenda: Learn about cutting-edge thermoplastic composites for durable, sustainable and cost-efficient battery housings Explore advanced automation concepts for efficient and scalable production See the latest large-tonnage equipment and technology innovations for e-mobility solutions

Plastics Technology’s Tech Days is back! Every Tuesday in October, a series of five online presentations will be given by industry supplier around the following topics: Injection Molding — New Technologies, Efficiencies Film Extrusion — New Technologies, Efficiencies Upstream/Downstream Operations Injection Molding — Sustainability Extrusion — Compounding Coming out of NPE2024, PT identified a variety of topics, technologies and trends that are driving and shaping the evolution of plastic products manufacturing — from recycling/recyclability and energy optimization to AI-based process control and automation implementation. PT Tech Days is designed to provide a robust, curated, accessible platform through which plastics professionals can explore these trends, have direct access to subject-matter experts and develop strategies for applying solutions in their operations.

Today’s 3D printing is an indisputably industrial suite, though, with attainable production-level efficiency. Together with the processes, the ways in which we refer to the technology have matured. No longer is “3D printing” or the original “rapid prototyping” the phrase bandied about in most professional labs; now, “additive manufacturing” or, more casually, AM, is the go-to terminology, placing these layer-by-layer processes squarely in the manufacturing realm.

The Plastics Industry Association (PLASTICS) has released final figures for NPE2024: The Plastics Show (May 6-10; Orlando) that officially make it the largest ever NPE in several key metrics.

Mixed in among thought leaders from leading suppliers to injection molders and mold makers at the 2023 Molding and MoldMaking conferences will be molders and toolmakers themselves.

Sarah Goehrke is the founder of AM-specific contract services company Additive Integrity; serves on the Board of Directors and as the Head of DEI at Women in 3D Printing; and sits on the Board of Advisors for the Additive Manufacturing Coalition. She focuses in the additive manufacturing industry on advances in diversity, sustainability, and ecosystem positioning with a heightened focus on messaging. Goehrke has been a leader in the 3D-printing industry since 2014, previously serving as the Managing Editor of Fabbaloo; Editor-in-Chief of 3DPrint.com; and Senior Director, Strategic Communications and Ecosystems at ultrafast 3D-printing leader Nexa3D. Through Additive Integrity, she has worked with more than two dozen companies across the industry, contributed to publications including Forbes.com, and keynoted across three continents. She is deeply and actively passionate about advancing diversity, equity, and inclusion in the 3D-printing industry. Goehrke holds bachelor’s degrees in English and Theatre from Muskingum College, as well as a certificate in Diversity & Inclusion for HR from Cornell University.

Examining other key metrics more closely, we see that Top Shops had more active molds (398 vs. 219) that molded more total parts (73 million vs. 32 million) for more active customers (102 vs. 56). Ultimately, it is that ability to wring maximum production from every person, every square foot, every tool and every machine that is part of what characterizes a Top Shop.

This Knowledge Center provides an overview of the considerations needed to understand the purchase, operation, and maintenance of a process cooling system.

Exhibitors and presenters at the plastics show emphasized 3D printing as a complement and aid to more traditional production processes.

In so many ways, AM remains an unknown quantity. Fewer materials, lower adoption, less training, and slower absolute per-part speeds combine into a difficult formula for adoption. The perception for some “big players” to keep their AM investment and use close to the vest as a “secret sauce” competitive secret also holds back the capability for many AM suppliers to tout their biggest success stories.

“We think our coworkers have a feel for how our operation is doing and strive to maintain a high level of engagement in operational efficiency and quality,” Porter says, noting that PlastiCert has a monthly “all coworker” meeting, which has become two meetings an hour apart as the business grows. In these meetings, leadership communicates revenue trends, areas of operational interest, new internal developments, and items of interest in the surrounding community. “We also pick a customer to tell workers more about how what we do for that customer contributes to its mission,” Porter says.

While an IM setup can be a huge upfront investment, the ROI is huge as its use scales. Indeed, peer-reviewed research indicates that “Injection molding is the best way to mass-produce small, precise polymer components with complex shapes.”

Ultradent's entry of its Umbrella cheek retractor took home the awards for Technical Sophistication and Achievement in Economics and Efficiency at PTXPO.

GETTING A QUOTE WITH LK-MOULD IS FREE AND SIMPLE.

FIND MORE OF OUR SERVICES:

Plastic Molding

Rapid Prototyping

Pressure Die Casting

Parts Assembly